Novel adsorbent for removing fluorine ions in wastewater and preparation method

An adsorbent and fluoride ion technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of increasing adsorption capacity and adsorption rate, so as to improve hydraulic performance, improve economy, The effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

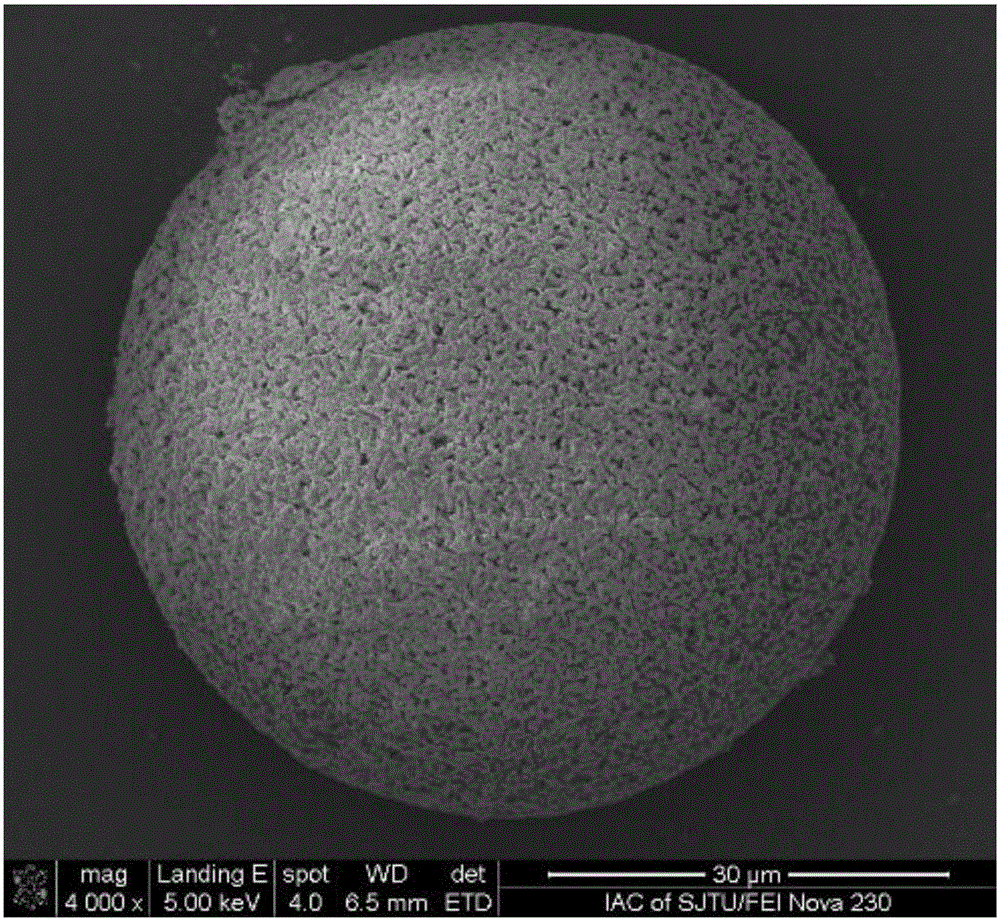

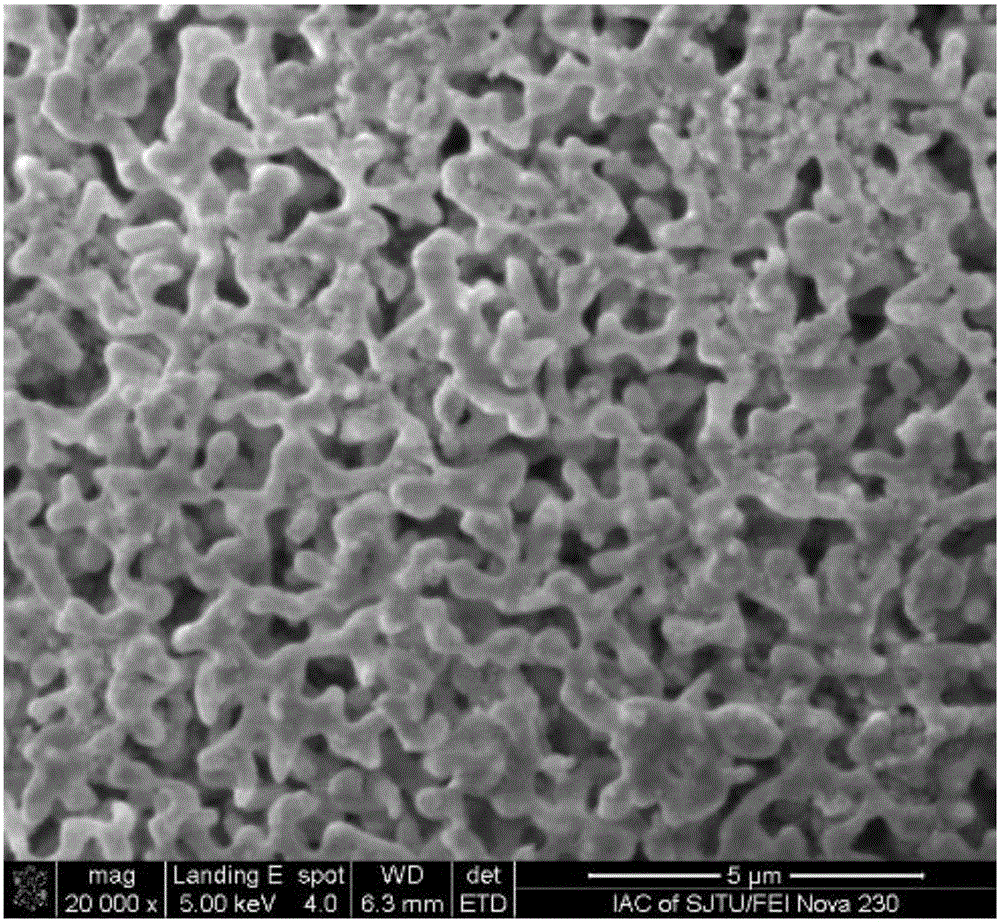

[0023] 1. Weigh 25g of Ce(NO 3 ) 3 ·6H 2 O was placed in a 1000mL pear-shaped bottle, added to 200mL methanol, and stirred to completely dissolve it. Then add 20g of SiO 2 .

[0024] 2. Use a rotary evaporator to rotate the above mixture at 0.5 atmospheric pressure for 1 hour, and then let it stand at atmospheric pressure for 1 hour.

[0025] 3. After standing still, use a rotary evaporator to carry out vacuum distillation of the above mixture under a 66°C water bath. The decompression process should be carried out slowly until the methanol in the pear-shaped bottle is basically evaporated to dryness, leaving only solids.

[0026] 4. Put the solid in the pear-shaped bottle in a vacuum drying oven, and dry under vacuum at 40° C. overnight.

[0027] 5. Put the above dried solid in a muffle furnace and calcinate at 250°C for 3 hours to obtain light yellow CeO 2 / SiO 2 Adsorbent.

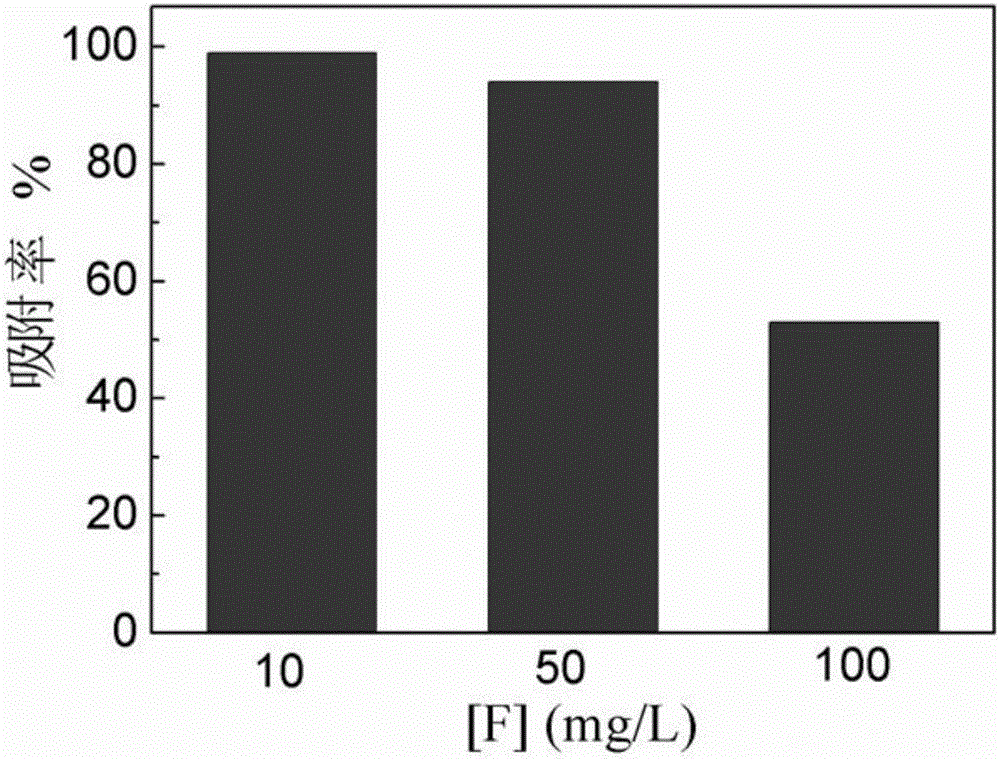

[0028] Implementation Case 2 Adsorption Experiment

[0029] CeO 2 / SiO 2 The adsorbent is...

Embodiment 3

[0030] Embodiment 3 regeneration experiment

[0031] 1. Add CeO 2 / SiO 2 The adsorbent is mixed with a solution with a pH of 3 and a fluoride ion solubility of 100mg / L at a solid-to-liquid ratio of 0.05g / 20mL, shaken in a water bath at 25°C for 5 hours, and then filtering the mixed solution to test the fluorine in the solution before and after adsorption. content, and then calculate the adsorption rate.

[0032] 2. The adsorbed CeO 2 / SiO 2 Dry the adsorbent, then mix it with 0.1mol / L NaOH solution at a solid-to-liquid ratio of 0.05g / 20mL, shake it in a water bath at 25°C for 5 hours, then filter the mixed solution, and test the fluorine content in the solution before and after desorption , and then calculate the desorption rate.

[0033] 3. The desorbed CeO 2 / SiO 2 The adsorbent was washed with distilled water until neutral, dried, and then re-adsorbed and desorbed according to steps 1 and 2, and cycled 4 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com