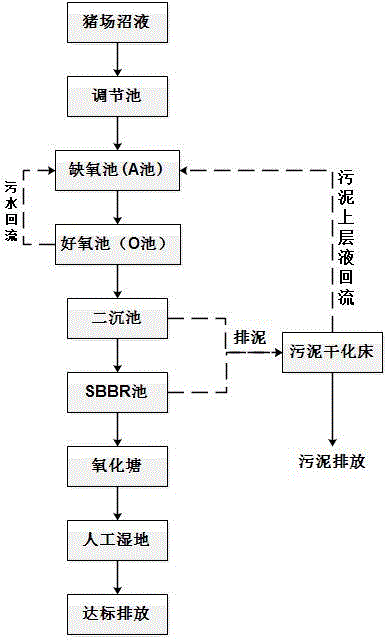

A/O-SBBR-oxidation pond-artificial wetland treatment pig farm biogas slurry technology

An O-SBBR-, artificial wetland technology, applied in the field of environmental science and engineering, can solve the problems of unstable treatment effect, difficult to meet the treatment standard, high operation and management costs, and achieve easy debugging and management, save chemical costs, and low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The processing capacity is 400m 3 / d pig farm biogas slurry, biogas slurry water quality: CODCr 1200~1500mg / L, NH 3 -N 500~630mg / L, TP 20~30mg / L, SS 450~800mg / L. The pig farm biogas slurry enters the adjustment pond after passing through the grille, and the water quality and water quantity are adjusted. Then the wastewater enters the anoxic section of the A / O process, where the hydrolysis and acidification of heterotrophic bacteria is used to degrade organic matter and improve the biodegradability of wastewater. The effluent from the anoxic section flows into the aerobic section, where a large amount of organic matter is degraded through microbial metabolism and most of the ammonia nitrogen is removed through nitrification under aerobic conditions. At the same time, part of the mixed liquid in the aerobic tank is controlled to flow back to the anoxic tank to improve the effect of denitrification and denitrification. Aerobic pool effluent CODCr 900~1000mg / L, NH 3 -N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com