Modification method and application of hollow glass microspheres

A technology of hollow glass microspheres and modification, applied in glass manufacturing equipment, manufacturing tools, etc., can solve problems such as uneven distribution, decreased compressive strength, unstable performance of cement slurry, etc., and achieve low permeability and small water loss , good mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

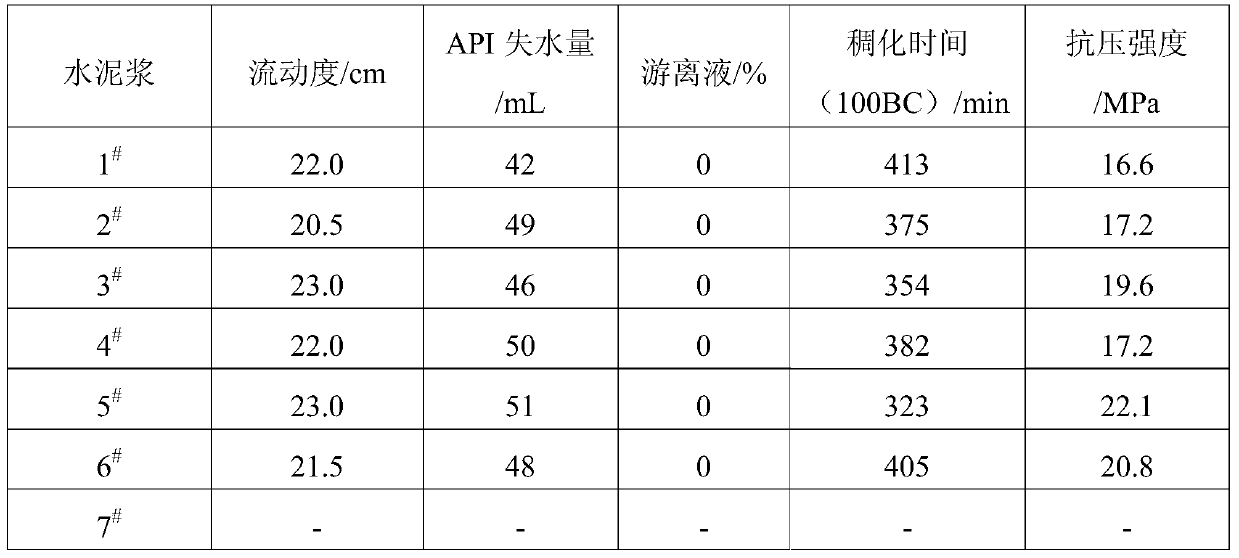

Examples

Embodiment 1

[0030] The modification of the hollow glass microspheres of the present embodiment is carried out according to the following steps:

[0031] 1) Cleaning treatment: select 400-mesh hollow glass microspheres 10g, fill them evenly in a glass vessel, place them in the chamber of the plasma processor, turn on the power, turn on the vacuum pump, and when the vacuum degree in the chamber reaches 9Pa, open the flow valve and put Air, when the air flow is stable to 0.5L / min, turn on the high-frequency power supply to clean the hollow glass microspheres, in which the power of the plasma processor is 50W; the cleaning time is 60s.

[0032] (2) Activation treatment: After finishing the cleaning treatment, keep the vacuum degree of the chamber at 9Pa, open the flow valve and put in oxygen, and when the oxygen flow rate is stabilized to 0.5L / min, turn on the high-frequency power supply to activate the hollow glass microspheres. Among them, the power of the plasma processor is 100W; the acti...

Embodiment 2

[0039] The modification of the hollow glass microspheres of the present embodiment is carried out according to the following steps:

[0040] 1) Cleaning treatment: Select 20g of 400-mesh hollow glass microspheres, fill them evenly in a glass container, place them in the cavity of the plasma processor, turn on the power, turn on the vacuum pump, and when the vacuum in the cavity reaches 9Pa, open the flow valve and put Oxygen, when the oxygen flow rate is stable to 0.5L / min, turn on the high-frequency power supply to clean the hollow glass microspheres, in which the power of the plasma processor is 120W; the cleaning time is 100s;

[0041] (2) Activation treatment: After finishing the cleaning treatment, keep the vacuum degree of the chamber at 9Pa, open the flow valve and put in oxygen, and when the oxygen flow rate is stabilized to 0.3L / min, turn on the high-frequency power supply to activate the hollow glass microspheres. Among them, the power of the plasma processor is 200W...

Embodiment 3

[0048] The modification of the hollow glass microspheres of the present embodiment is carried out according to the following steps:

[0049] 1) Cleaning treatment: Select 400-mesh hollow glass microspheres 15g, fill them evenly in a glass vessel, place them in the chamber of the plasma processor, turn on the power, turn on the vacuum pump, and when the vacuum degree in the chamber reaches 7Pa, open the flow valve and put Air, when the air flow is stable to 0.5L / min, turn on the high-frequency power supply to clean the hollow glass beads, in which the power of the plasma processor is 100W; the cleaning time is 80s;

[0050] (2) Activation treatment: After finishing the cleaning treatment, keep the vacuum degree of the cavity at 7Pa, open the flow valve and put in the mixture of air and nitrogen. Turn on the high-frequency power supply to activate the hollow glass microspheres, wherein the power of the plasma processor is 150W; the activation treatment time is 100s;

[0051] (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com