Zirconia ceramic for oil/gas well and preparation method of zirconia ceramic

A technology for zirconia ceramics and oil and gas wells, applied in the field of ceramics, can solve problems such as excessive friction coefficient, low friction coefficient, and high sintering temperature, and achieve the effects of low friction coefficient, lower sintering temperature, and increase density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

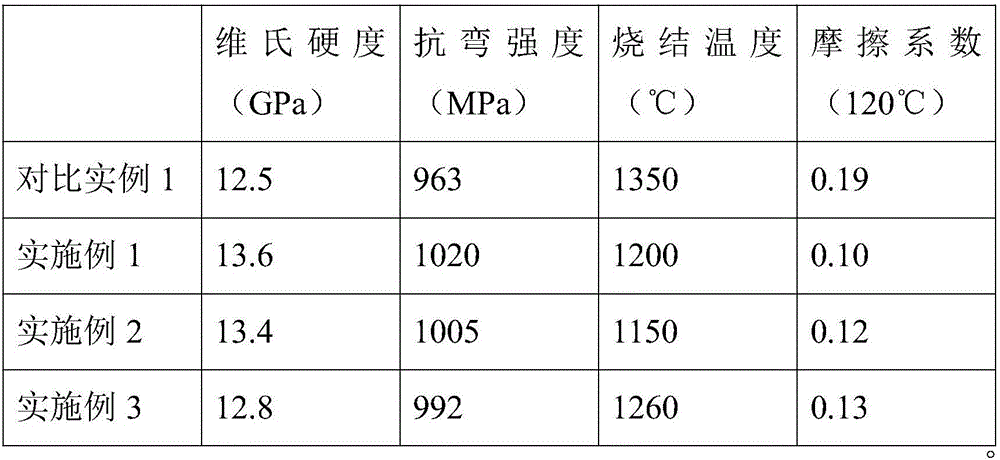

Examples

Embodiment 1

[0026] A zirconia ceramic for oil and gas wells, calculated in parts by weight, comprising the following raw materials:

[0027] 62 parts of zirconium oxide, 2 parts of millionth oxide, 0.5 part of lanthanum oxide, 1.5 parts of samarium oxide, 1 part of graphite, 2 parts of molybdenum carbide, 1 part of methyl cellulose and 1 part of polyammonium methacrylate; wherein, the graphite and Molybdenum carbide needs to be soaked in dilute nitric acid first, and then solid-liquid separation.

[0028] The preparation method comprises the following steps:

[0029] 1) Pretreatment: graphite and molybdenum carbide need to be soaked in 1mol / L dilute nitric acid for 30 minutes, and then separated from solid and liquid to obtain pretreated graphite and molybdenum carbide;

[0030] 2) Ball milling powder: Weigh zirconia, 100 million oxide, lanthanum oxide and samarium oxide according to the ratio, and then mix them with pretreated graphite and molybdenum carbide and add them to the ball mil...

Embodiment 2

[0036] A zirconia ceramic for oil and gas wells, calculated in parts by weight, comprising the following raw materials:

[0037] 70 parts of zirconium oxide, 1.5 parts of millionth oxide, 0.4 part of lanthanum oxide, 0.5 part of samarium oxide, 1.5 parts of graphite, 4 parts of molybdenum carbide, 2 parts of ethyl cellulose and 2 parts of polyammonium methacrylate; wherein, the graphite and Molybdenum carbide needs to be soaked in dilute nitric acid first, and then solid-liquid separation.

[0038] The preparation method comprises the following steps:

[0039] 1) Pretreatment: graphite and molybdenum carbide need to be soaked in 0.5mol / L dilute nitric acid for 40 minutes, and then separated from solid and liquid to obtain pretreated graphite and molybdenum carbide;

[0040] 2) Ball milling powder: Weigh zirconia, 100 million oxide, lanthanum oxide and samarium oxide according to the ratio, and then mix them with pretreated graphite and molybdenum carbide and add them to the b...

Embodiment 3

[0046] A zirconia ceramic for oil and gas wells, calculated in parts by weight, comprising the following raw materials:

[0047]60 parts of zirconium oxide, 2.5 parts of millionth oxide, 1.2 parts of lanthanum oxide, 1.5 parts of samarium oxide, 0.5 parts of graphite, 2 parts of molybdenum carbide, 1.5 parts of ethyl cellulose and 1.5 parts of polyammonium methacrylate; wherein, the graphite and Molybdenum carbide needs to be soaked in dilute nitric acid first, and then solid-liquid separation.

[0048] The preparation method comprises the following steps:

[0049] 1) Pretreatment: graphite and molybdenum carbide need to be soaked in 3mol / L dilute nitric acid for 20 minutes, and then separated from solid and liquid to obtain pretreated graphite and molybdenum carbide;

[0050] 2) Ball milling powder: Weigh zirconia, billionth oxide, lanthanum oxide and samarium oxide according to the ratio, and then mix them with pretreated graphite and molybdenum carbide and add them to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com