Preparation process for cornstalk pentosane sulfate

A straw pentosan sulfate ester and preparation process technology, which is applied in the structural transformation and application field of natural products, can solve the problems of low sulfuric acid substitution degree of esterification products and high equipment requirements, and achieve good market application prospects and sulfation degree High, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

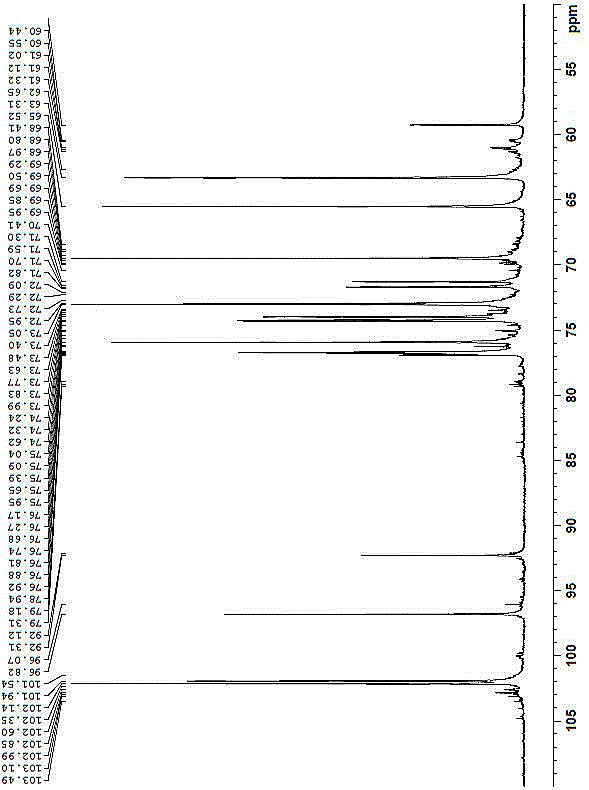

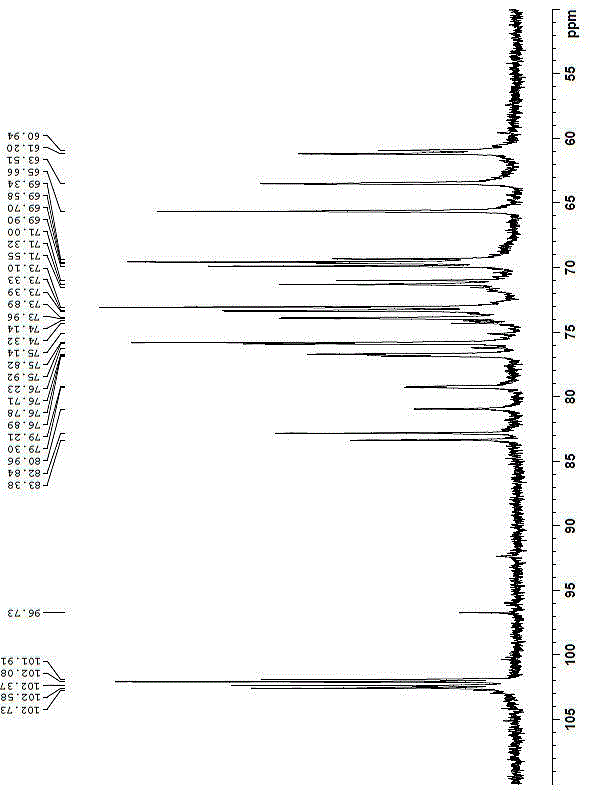

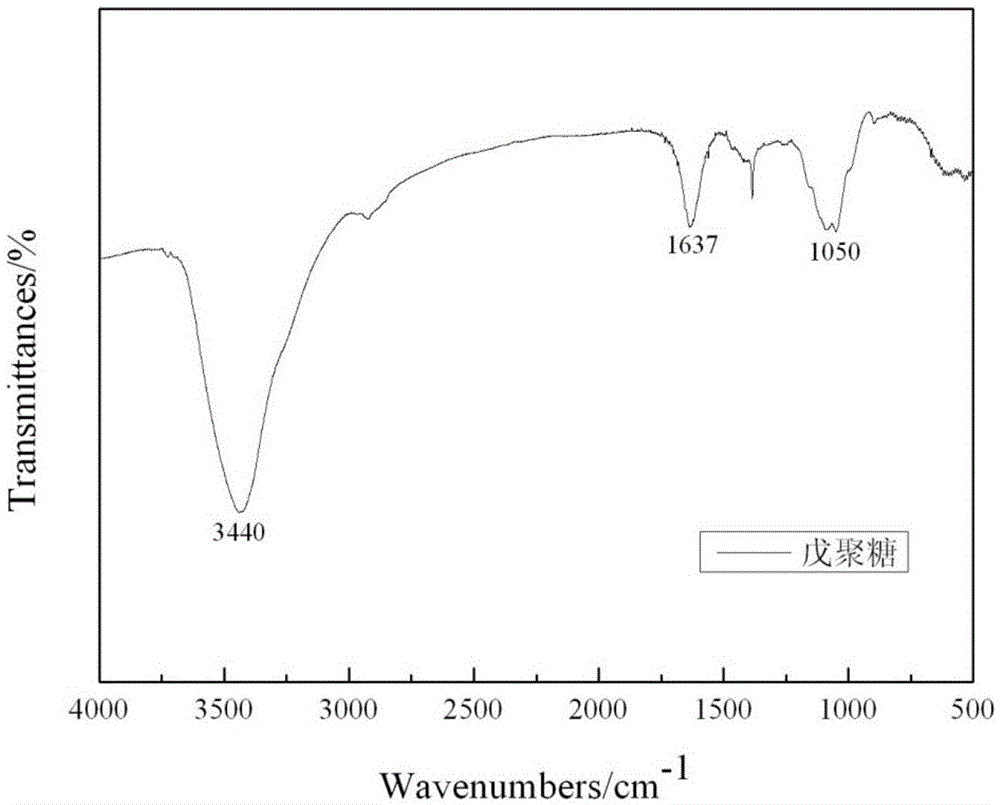

Image

Examples

Embodiment 1

[0025] 1. Extraction of Corn Stalk Pentosans

[0026] Add 4g of corn stalks (screened through a 60-mesh standard sieve) into 120mL of NaOH solution (ω is 10%), and react at 70°C for 6h. Suction filtration, adjust the pH of the filtrate to 7 with HCl (ω is 9%), concentrate in vacuo to 80 mL, cool to room temperature, add 240 mL of absolute ethanol to settle, and settle at 0°C for 9 hours. Suction filtration, the filter cake was washed 3 times with 20 mL of absolute ethanol, and the filter cake was dried in a vacuum oven at 30° C. for 12 hours to obtain crude pentosan.

[0027] 2. Purification of Corn Stalk Pentosans

[0028] (1) Recrystallization: Add the crude pentosan in Example 1 into 50 mL of NaOH solution (ω is 5%), stir and dissolve, filter with suction, add HCl dropwise to the filtrate (ω is 9%) to adjust the pH of the solution to 7. Concentrate in vacuo to 30 mL, add 90 mL of absolute ethanol after cooling, produce a large amount of white crystals, settle for 8 hours,...

Embodiment 2

[0032] 1. Preparation of Pentosan Sulfate

[0033] (1) Add 40mLNaHSO 3 The solution (ω is 32.5%) was added to a 100mL three-necked flask with a thermometer and a condenser, and slowly added dropwise 10mL NaNO 2 solution (ω is 20%), control the rate of addition, 20 minutes to complete the drop. React at 90°C for 1.5h to obtain the esterification reagent sodium aminotrisulfonate solution (ω is 18.7%).

[0034] (2) Adjust the pH of the sodium aminotrisulfonate solution obtained in step (1) to 9 with NaOH (ω is 5%), add 2g of pentosan from Example 1, and react at 50°C for 5h.

[0035] (3) Concentrate the reaction solution obtained in step (2) to 20 mL in vacuo, add 60 mL of absolute ethanol, settle for 1 hour, filter with suction, and rinse the filter cake with 20 mL of absolute ethanol three times.

[0036] (4) Add 20mL of distilled water to the filter cake obtained in step (3), stir to dissolve, then add 5mL of HCl (ω is 18%) dropwise for acidification, add dropwise slowly, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com