Anti-adhesive weather-resistant coatings, bonding coats for bonding waterstops to concrete, composite waterproofing systems

A technology of anti-adhesive weather resistance and weather resistance, which is applied in the direction of coatings, building insulation materials, building components, etc., and can solve the problem of adhesive layer type, bonding effect, weather resistance, indeterminate functionality, reduced weather resistance, and reduced adhesive performance And other problems, to achieve excellent interface bonding performance, slow down the aging speed, enhance the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

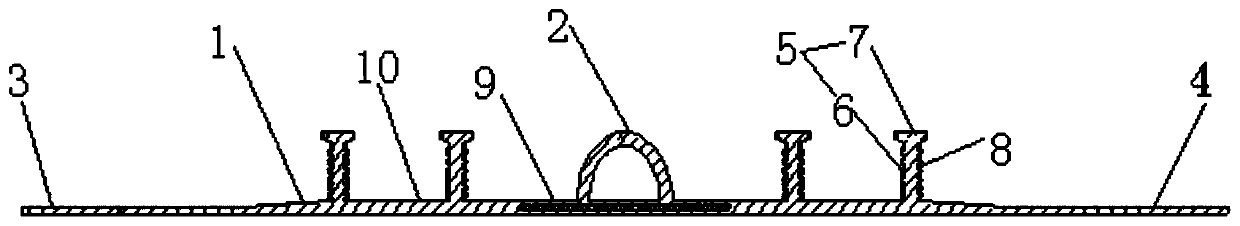

Image

Examples

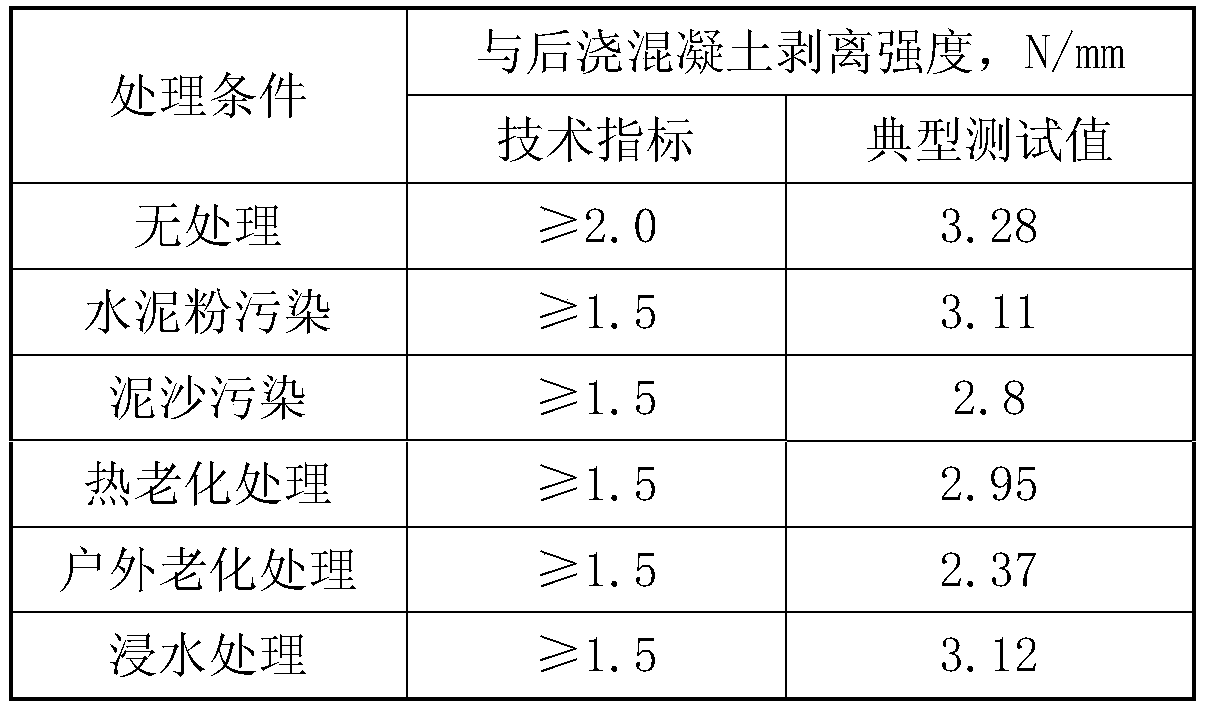

Embodiment 1

[0033] This embodiment provides a kind of anti-adhesive and weather-resistant coating, and its formulation raw materials include: heavy calcium carbonate, talcum powder, titanium dioxide and water-based emulsion, and the water-based emulsion contains functional groups that can coordinate and complex with basic groups in concrete .

[0034] This embodiment also provides an adhesive layer for bonding waterstops and concrete, including a pressure-sensitive adhesive layer and an anti-adhesive weather-resistant coating arranged on the pressure-sensitive adhesive layer. The material of the pressure-sensitive adhesive layer is pressure-sensitive adhesive layer. The material of the sensitive adhesive and anti-adhesive weather-resistant coating is the above-mentioned anti-adhesive weather-resistant coating, the pressure-sensitive adhesive layer is used to be arranged on the waterstop, and the adhesive layer is used to be arranged between the waterstop and the concrete.

[0035] The ant...

Embodiment 2

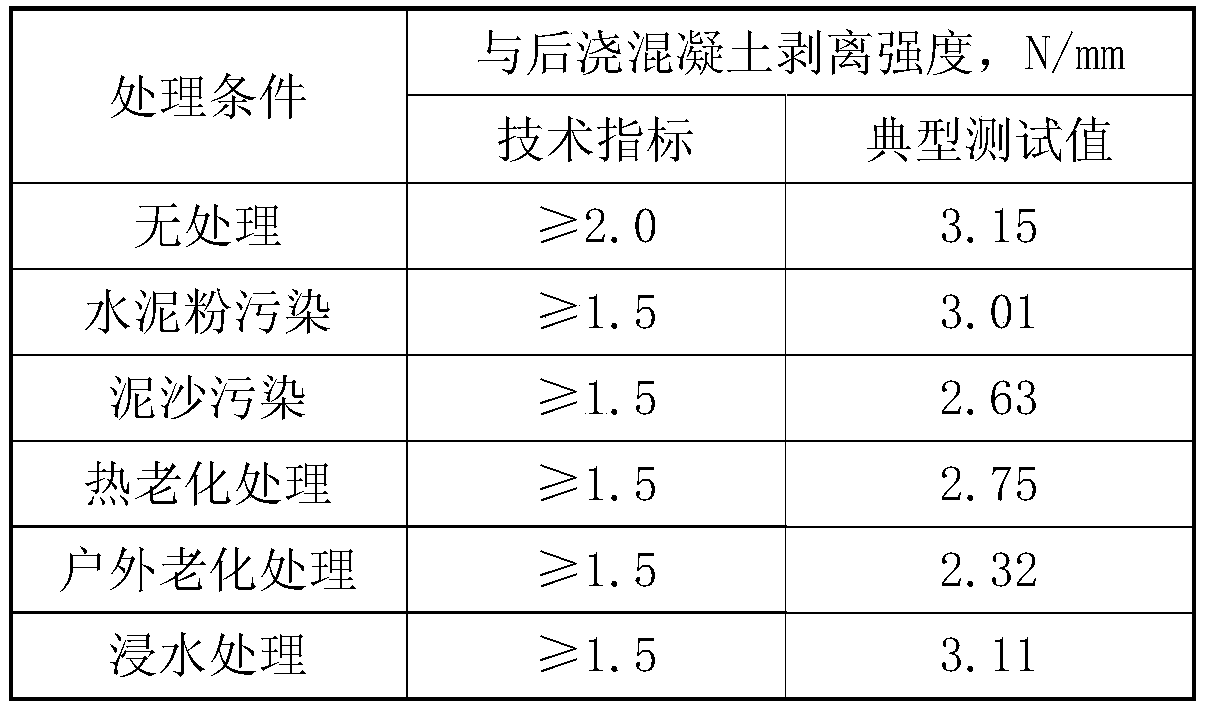

[0043] The present embodiment provides a kind of anti-adhesive weather-resistant coating, and its formula raw material comprises: the ground calcium carbonate of 62 weight parts, the talcum powder of 4 weight parts, the titanium dioxide of 2 weight parts and the water-based emulsion of 272 weight parts, in the water-based emulsion Contains functional groups that can coordinate and complex with basic groups in concrete. The functional group in the aqueous emulsion that can coordinate and complex with the basic group in the concrete is silicate.

[0044] Heavy calcium carbonate is the first heavy calcium carbonate and the second heavy calcium carbonate, the ratio of the particle size of the first heavy calcium carbonate to the particle size of the second heavy calcium carbonate is 1:10; the first heavy calcium carbonate The weight ratio of calcium to the second heavy calcium carbonate is 1:61; the particle diameter of the first heavy calcium carbonate is 800 mesh, and the partic...

Embodiment 3

[0062] The present embodiment provides a kind of anti-adhesive weather-resistant coating, and its formulation raw material comprises: the ground calcium carbonate of 61 weight parts, the talcum powder of 4 weight parts, the titanium dioxide of 3 weight parts and the aqueous emulsion of 320 weight parts, in the aqueous emulsion Contains functional groups that can coordinate and complex with basic groups in concrete.

[0063] Heavy calcium carbonate is the first heavy calcium carbonate and the second heavy calcium carbonate, the ratio of the particle size of the first heavy calcium carbonate to the particle size of the second heavy calcium carbonate is 1:10; the first heavy calcium carbonate The weight ratio of calcium to the second heavy calcium carbonate is 2:59; the particle diameter of the first heavy calcium carbonate is 800 mesh, and the particle diameter of the second heavy calcium carbonate is 80 mesh.

[0064] The water-based emulsion includes pure acrylic emulsion and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com