High-performance flame-retardant double-component silane modified polyether sealant and preparation method thereof

A silane-modified polyether, flame-retardant technology, applied in the field of sealants, can solve problems such as difficult to meet the flame-retardant performance requirements of sealant products, and achieve good curing rate stability and construction stability, good mechanical properties, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

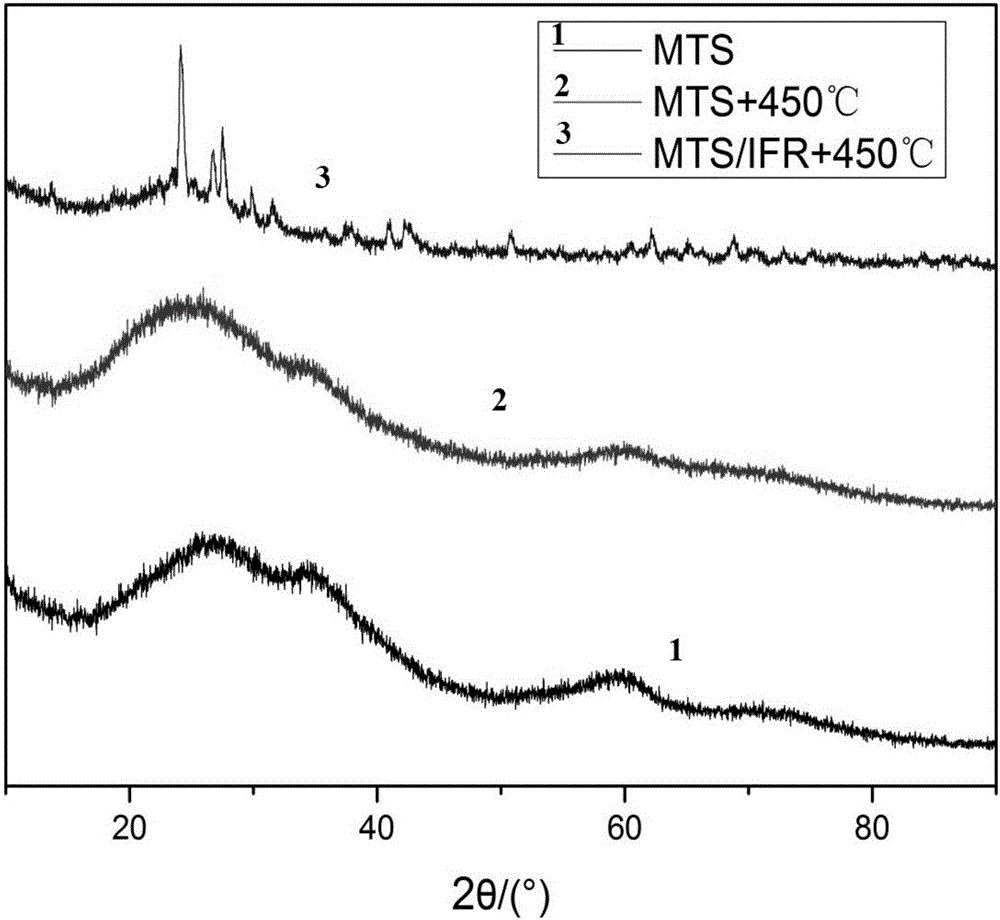

Image

Examples

Embodiment 1

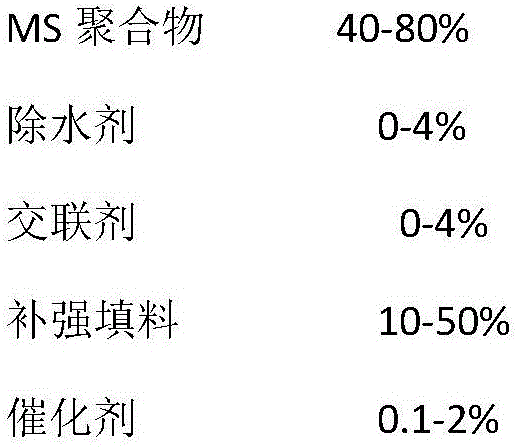

[0030] Component A:

[0031]

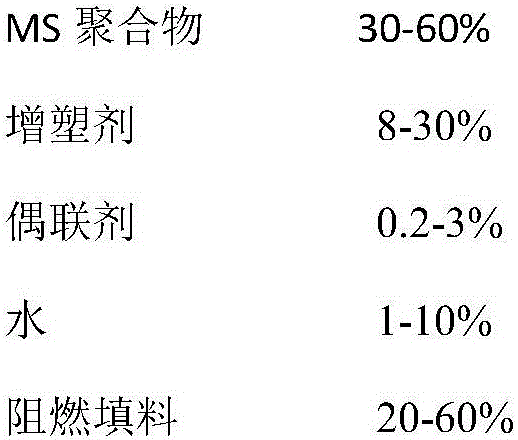

[0032] The ratio of component B:

[0033]

[0034] Flame retardant filler:

[0035] Magnesium Trisilicate 30%

[0036] Ammonium polyphosphate 50%

[0037] Pentaerythritol 20%.

Embodiment 2

[0039] Component A:

[0040]

[0041] Component B:

[0042]

[0043] Flame retardant filler:

[0044]

[0045]

Embodiment 3

[0047] Component A:

[0048]

[0049] Component B:

[0050]

[0051] Flame retardant filler:

[0052] Magnesium Trisilicate 25%

[0053] Melamine polyphosphate 55%

[0054] Pentaerythritol 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com