A kind of graphene oxide reinforced magnesium-based composite material and preparation method thereof

A composite material and manufacturing method technology, applied in the field of materials, can solve the problems affecting the properties of graphene oxide reinforced magnesium-based composite materials, the relationship between graphene and metal matrix is not clear, the shape and dispersion uniformity are difficult to control, etc., to achieve Promoting sustainable development, reducing the probability of oxidation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of the graphene oxide reinforced magnesium-based composite material provided in this embodiment comprises the following steps:

[0039]S1: Mix graphite oxide and water according to the dosage ratio of 0.25g:50mL, and ultrasonically disperse at 20KHz for 20min to obtain a graphene oxide dispersion;

[0040] S2: The graphene oxide dispersion was mixed with CTAB and AZ80 magnesium chips, and then dried at 0.08MPa and 35°C to obtain chip-like composite materials; wherein, the dosage ratio of graphite oxide, CTAB, and AZ80 magnesium chips was 0.25g: 200mL: 89.60g;

[0041] S3: Heating the crumb-like composite material to 250° C. and keeping it warm for 20 minutes, and then pressing it into shape.

[0042] This embodiment also provides a graphene oxide-reinforced magnesium-based composite material prepared by the above-mentioned method for producing a graphene oxide-reinforced magnesium-based composite material.

Embodiment 2

[0044] The preparation method of the graphene oxide reinforced magnesium-based composite material provided in this embodiment comprises the following steps:

[0045] S1: Mix graphite oxide and water according to the dosage ratio of 0.30g:100mL, ultrasonically disperse at 40KHz for 10min to obtain a graphene oxide dispersion, and put the graphene oxide dispersion into a sealed container for later use;

[0046] S2: Ultrasonic cleaning of AZ31 magnesium chips at 40KHz for 10 minutes;

[0047] Add graphene oxide dispersion into water and mix, then ultrasonically disperse at 40KHz for 20min, then add the cleaned AZ31 magnesium chips, mechanically stir for 10min, then ultrasonically disperse at 40KHz for 20min to obtain a mixed solution, and place the mixed solution at 0.098 Dry at MPa and 100°C to obtain chip-like composite materials; wherein, the dosage ratio of graphite oxide, water, and AZ31 magnesium chips is 0.30g: 200mL: 89.80g;

[0048] S3: Heating the crumb-like composite ...

Embodiment 3

[0051] The preparation method of the graphene oxide reinforced magnesium-based composite material provided in this embodiment comprises the following steps:

[0052] S1: Mix graphite oxide and water according to the dosage ratio of 0.27g:75mL, ultrasonically disperse at 30KHz for 15 minutes to obtain a graphene oxide dispersion, and then put the graphene oxide dispersion into a sealed container for later use;

[0053] S2: Ultrasonic cleaning of AZ31 magnesium chips at 30KHz for 15 minutes;

[0054] Add the graphene oxide dispersion obtained in step S1 to 200mL of analytical alcohol with a purity of 99.99%, mix, and then ultrasonically disperse at 30KHz for 30min, then add 89.73g of AZ31 magnesium chips after cleaning, mechanically stir for 5min and then dissolve at 30KHz Under ultrasonic dispersion treatment for 30min, the mixed solution was obtained, and the mixed solution was dried at 0.087MPa and 50°C to obtain 90g of crumb composite material;

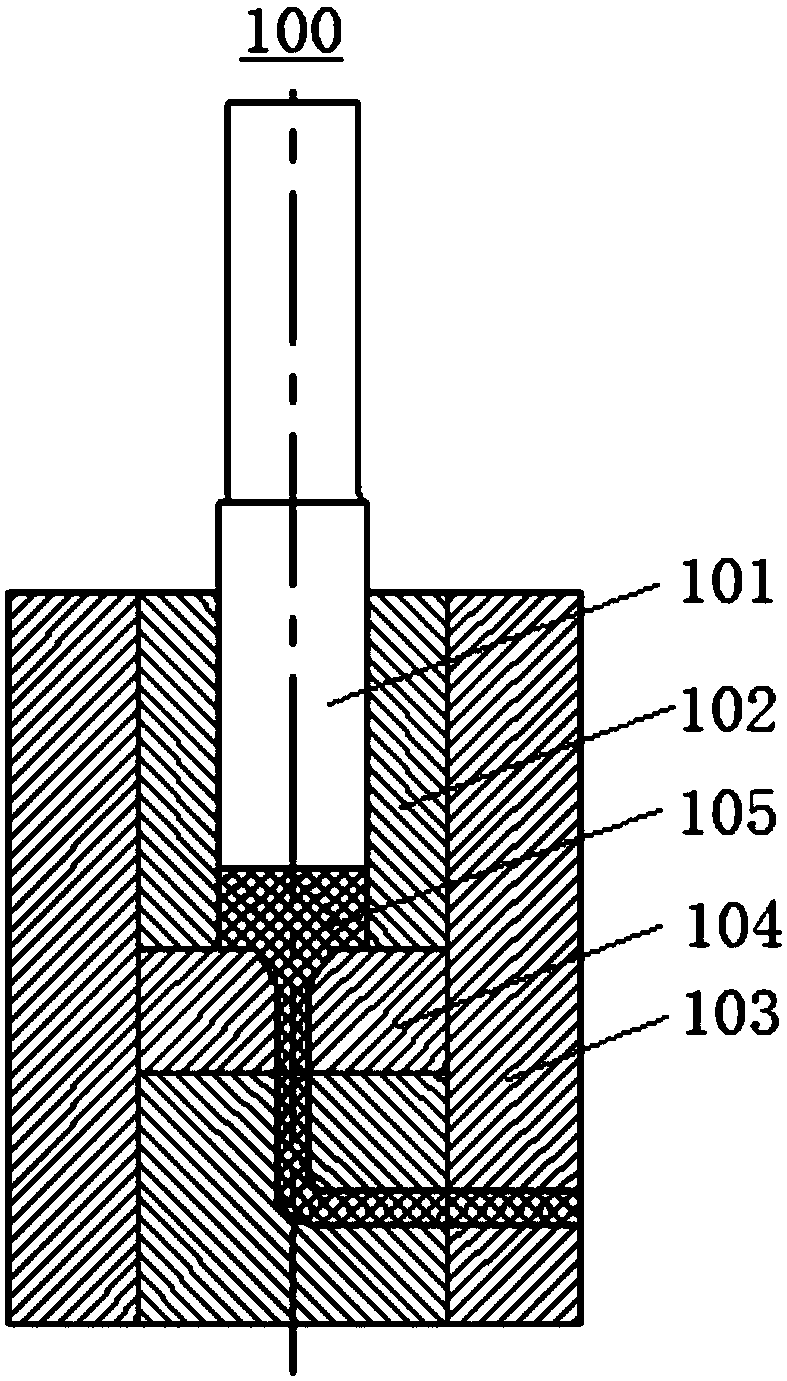

[0055] S3: if figure 1 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com