Transparent super-hydrophobic film and preparation method and application thereof

A super-hydrophobic, thin-film technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of poor performance, large pollution, long and complicated experimental process, etc., and achieve the effect of good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Prepare transparent superhydrophobic film on n-Si surface, preparation method is as follows:

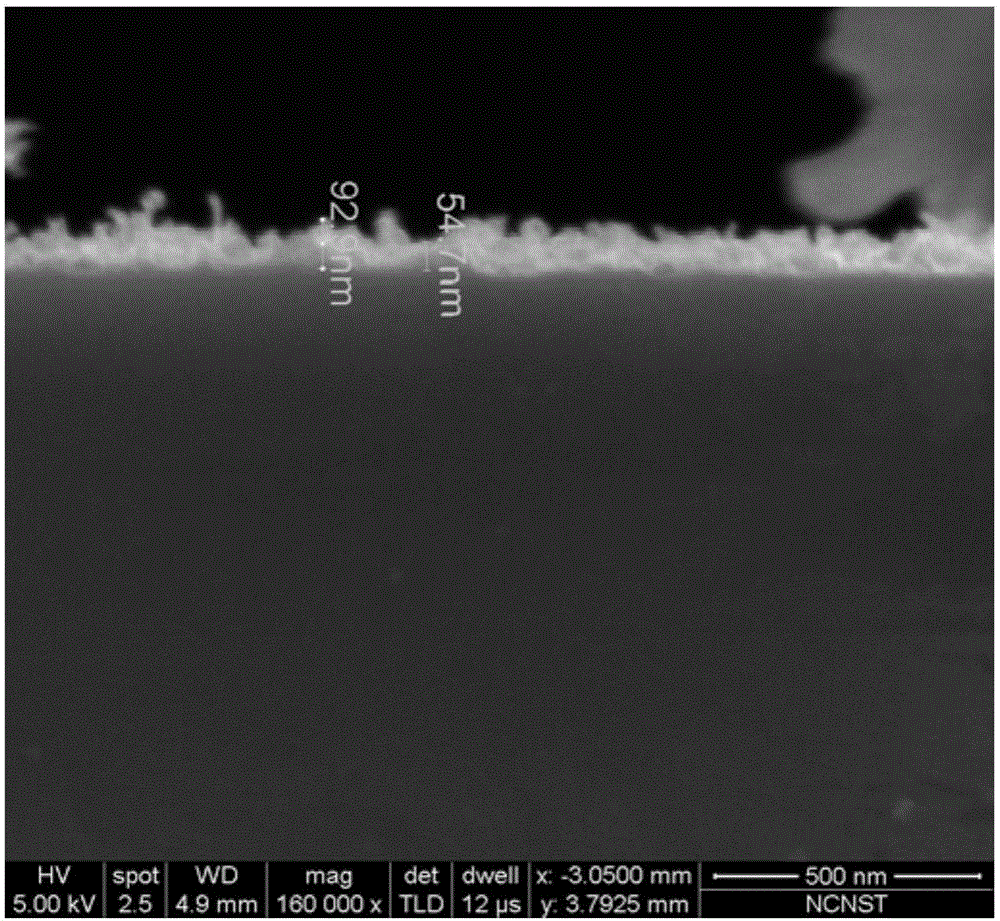

[0081] 1) The cleaned n-Si is placed on a magnetron sputtering substrate stage, an ultrapure zinc target with a purity of 99.999% is used as a sputtering source, and ultrapure argon is used as a working gas to prepare a zinc film. During the preparation of the zinc film, vacuumize until the background vacuum exceeds 10 - 7 torr; the working pressure is 8mtorr; the substrate temperature is room temperature; the RF power is 150w; the deposition time is 50min.

[0082] 2) The sample obtained in step 1) (the zinc film is supported on the upper surface of the n-Si substrate) is placed on the substrate stage of magnetron sputtering to anneal the zinc film to prepare a zinc oxide film. Vacuum until the background vacuum exceeds 10 -6 torr; heat the substrate to 350°C, feed high-purity oxygen 10 sccm, and anneal in an oxygen atmosphere for 1 hour; then raise the substrate temperatu...

Embodiment 2

[0088] Except that the substrate was replaced by ordinary glass (Glass), and the fluorination treatment time of step 3) was adjusted to 20s, other preparation methods and conditions were the same as in Example 1.

[0089] The product prepared in this embodiment is composed of ordinary glass and a transparent super-hydrophobic film loaded on its surface, named glass coated with self-cleaning film.

[0090] Figure 3a The surface topography figure of the product prepared for this embodiment, as can be seen from the figure, the surface of the transparent self-cleaning film is rough, and many irregular nanorods are distributed.

[0091] Figure 3b The measured contact angle diagram of the product prepared for this example and water, it can be seen from the figure that the contact angle with water is >170°, and it has superhydrophobicity.

[0092] Figure 4 It is a comparison chart of the spectral curves of the product prepared in Example 2 and the ordinary glass of Comparative ...

Embodiment 3

[0094] Except that the substrate was replaced by K9 glass, and the deposition time of step 1) was adjusted to 1 h, other preparation methods and conditions were the same as in Example 2.

[0095] The product prepared in this embodiment is composed of K9 glass and a transparent super-hydrophobic film loaded on its surface.

[0096] Figure 5a The AFM image of the product prepared in this embodiment shows that the roughness Ra=57.

[0097] Figure 5b The measured contact angle diagram of the product prepared for this example and water, it can be seen from the figure that the contact angle with water>170°, which has excellent superhydrophobicity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com