A method of supercritical carbon dioxide enzymatic cooking, bleaching and dyeing of hemp roving

A carbon dioxide and supercritical technology, applied in dyeing, enzyme/microbial biochemical treatment, plant fiber, etc., can solve the problems of high water consumption, hemp fiber roving boiling and bleaching, and high pollution in the dyeing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087]Hemicellulase, pectinase and glucose oxidase were purchased from Jiangsu Ruiyang Biotechnology Co., Ltd. Hemicellulase: activity ≥ 20000U / g, applicable pH value 4.0-5.5, optimal pH value 4.5-5, applicable temperature 30-60℃, the best temperature is 45-50℃; pectinase: activity ≥ 10000U / g, suitable pH value is 3.5-6.5, the best pH value is 5.5-6, suitable temperature is 45-65℃, the best temperature is 50- 55°C; Glucose oxidase: activity ≥300U / g, applicable pH value 4.0-5.5, optimum pH value 3.5-6.5, applicable temperature 20-70°C, optimum temperature 50-55°C. Prepare hemicellulase, pectinase, and glucose oxidase in a ratio of 1:1:1 to form a compound biological enzyme solution with a concentration of 1%, stir evenly and set aside.

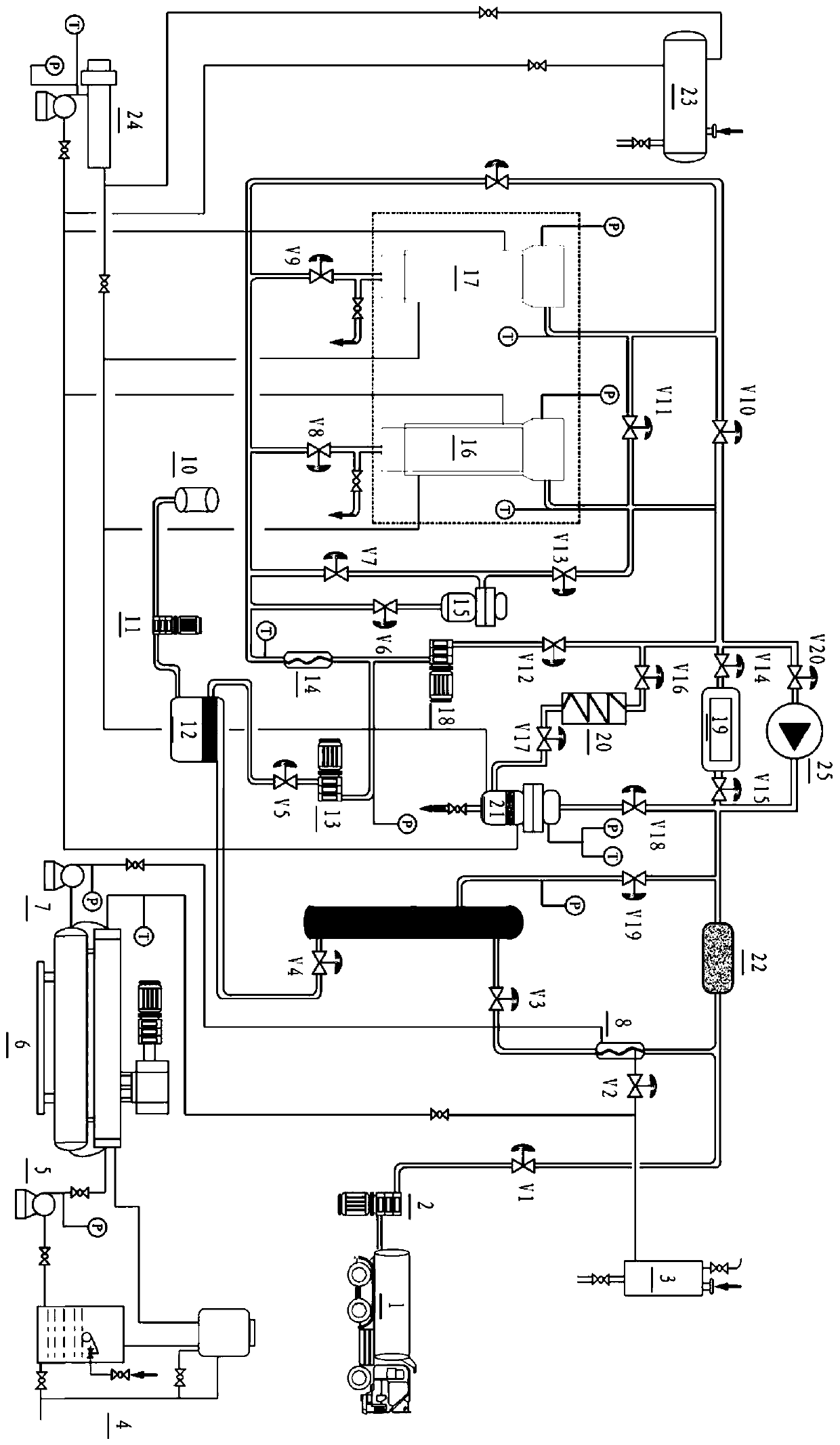

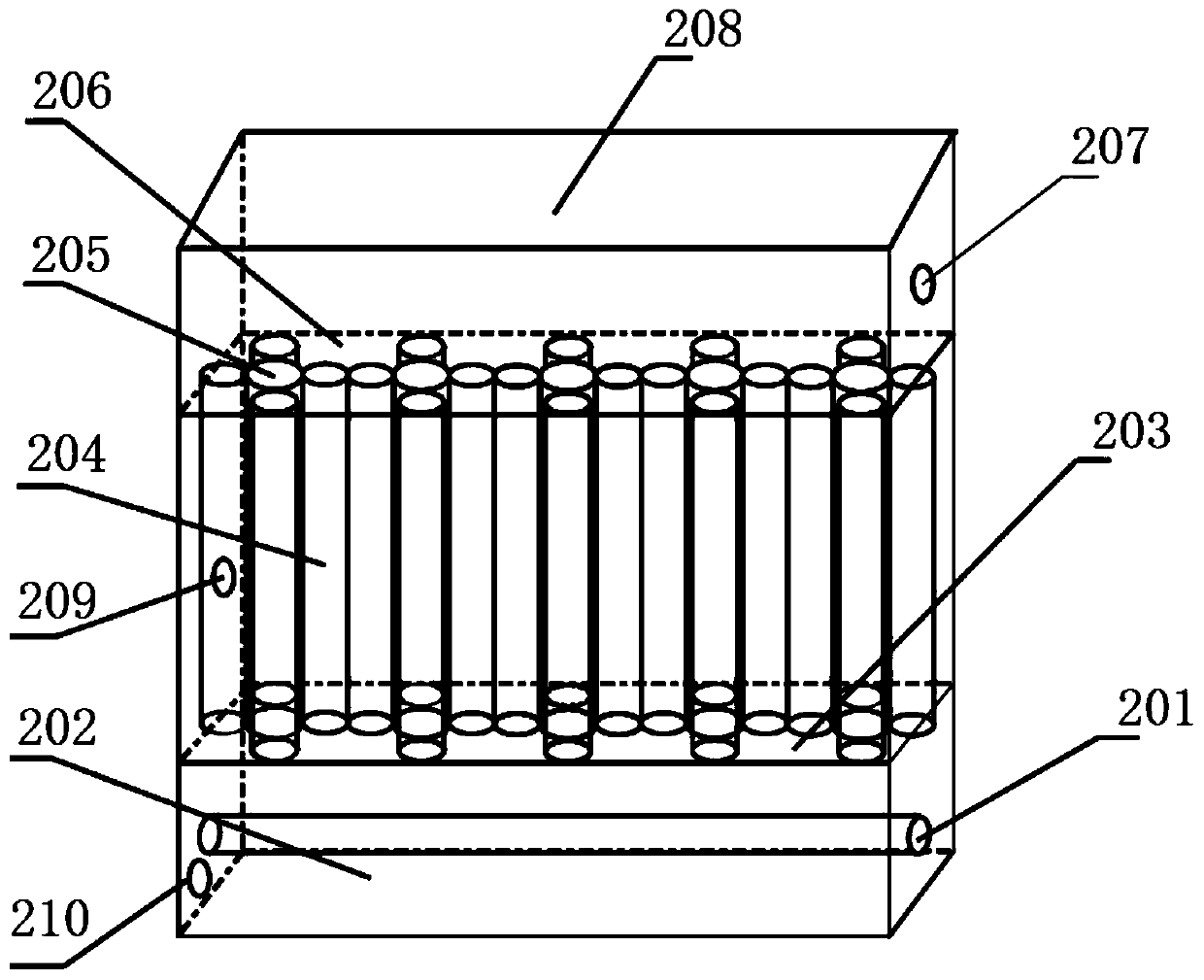

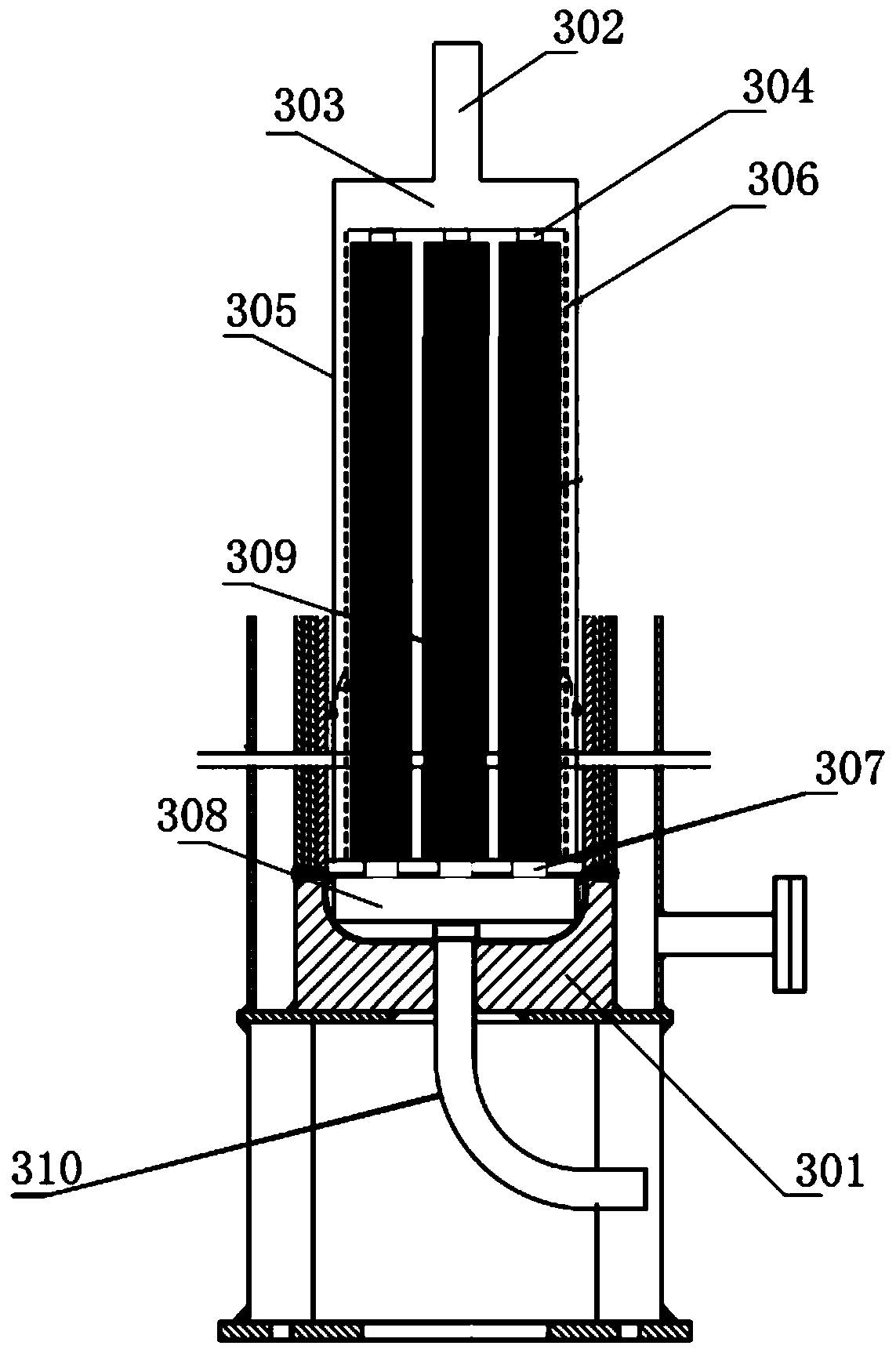

[0088] Put 10kg flax roving, 1% (o.w.f.) of disperse dye and 1% compound biological enzyme solution into supercritical carbon dioxide cooking, bleaching and dyeing kettle 16, 17, dye kettle 15 and co-solvent tank 10 in sequence; open gas storag...

Embodiment 2

[0092] Hemicellulase, pectinase and glucose oxidase were purchased from Jiangsu Ruiyang Biotechnology Co., Ltd. Hemicellulase: activity ≥ 20000U / g, applicable pH value 4.0-5.5, optimal pH value 4.5-5, applicable temperature 30-60℃, the best temperature is 45-50℃; pectinase: activity ≥ 10000U / g, suitable pH value is 3.5-6.5, the best pH value is 5.5-6, suitable temperature is 45-65℃, the best temperature is 50- 55°C; Glucose oxidase: activity ≥300U / g, applicable pH value 4.0-5.5, optimum pH value 3.5-6.5, applicable temperature 20-70°C, optimum temperature 50-55°C. Prepare hemicellulase, pectinase, and glucose oxidase in a ratio of 1:1:3 to form a compound biological enzyme solution with a concentration of 4%, stir evenly and set aside.

[0093] Put 15kg ramie roving, 2% (o.w.f.) of reactive disperse dyes and 4% compound biological enzyme solution into supercritical carbon dioxide cooking, bleaching and dyeing kettle 16, 17, dye kettle 15 and co-solvent tank 10 successively; op...

Embodiment 3

[0097] Hemicellulase, pectinase and glucose oxidase were purchased from Jiangsu Ruiyang Biotechnology Co., Ltd. Hemicellulase: activity ≥ 20000U / g, applicable pH value 4.0-5.5, optimal pH value 4.5-5, applicable temperature 30-60℃, the best temperature is 45-50℃; pectinase: activity ≥ 10000U / g, suitable pH value is 3.5-6.5, the best pH value is 5.5-6, suitable temperature is 45-65℃, the best temperature is 50- 55°C; Glucose oxidase: activity ≥300U / g, applicable pH value 4.0-5.5, optimum pH value 3.5-6.5, applicable temperature 20-70°C, optimum temperature 50-55°C. Prepare hemicellulase, pectinase, and glucose oxidase in a ratio of 1:2:3 to form a compound biological enzyme solution with a concentration of 3%, stir evenly and set aside.

[0098] Put 20kg hemp roving, reactive dye 1.5% (o.w.f.) and concentration 3% compound biological enzyme solution into supercritical carbon dioxide cooking, bleaching and dyeing kettle 16, 17, dye kettle 15 and co-solvent tank 10 successively; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com