Homogenized white light source and homogenizing method

A technology of white light source and light source, which is applied to optical elements, lighting devices, and components of lighting devices for changing the spectral characteristics of emitted light, etc. Changes in properties, etc., to achieve the effect of controllable and stable color temperature and color rendering index, improving long-term stability, and reducing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

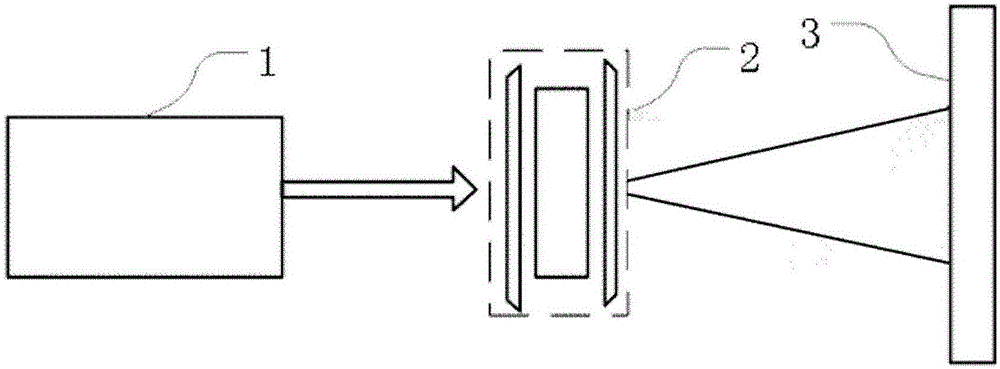

[0060] Such as figure 1 As shown, this embodiment proposes a homogenized white light source, including a light source 1, a homogenization system 2 and a fluorescent conversion device 3, wherein:

[0061] Light source 1 is a point light source for emitting light beams;

[0062] The homogenization system 2 is used to homogenize the beam so that the beam forms a homogenized surface light source;

[0063] The fluorescent conversion device 3 is used to receive and convert the light beam of the homogenized surface light source to form homogenized white light.

[0064] The above-mentioned light source 1 is a blue laser diode with a center wavelength of 450nm, which is output through optical fiber coupling.

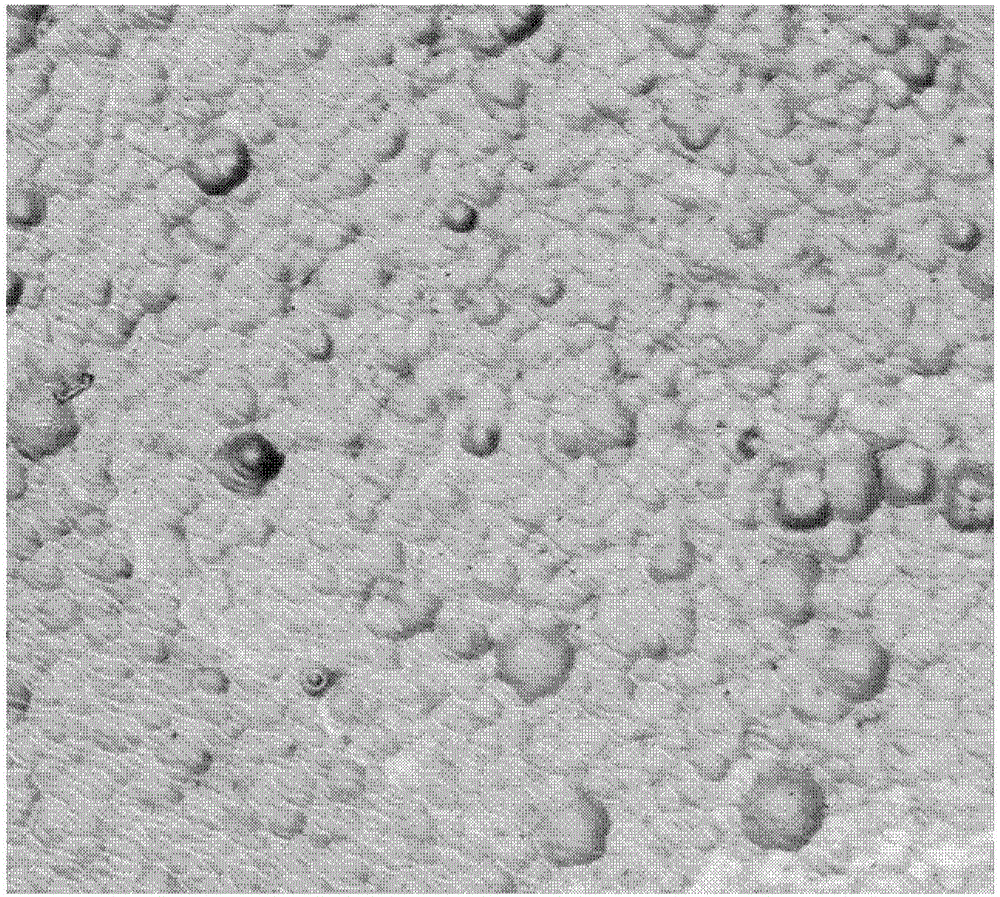

[0065] The above-mentioned homogenization system 2 adopts a diffusion sheet with a surface structure as shown in FIG. 2 , so that the point light source of the blue laser diode irradiated on the diffusion sheet becomes a diffuse and homogenized surface light source. Figure 2(a...

Embodiment 2

[0069] Such as Figure 4 As shown, this embodiment proposes a homogenized white light source, including a plurality of light sources and a homogenization system, wherein:

[0070] Multiple light sources are point light sources for emitting beams of different wavelengths;

[0071] The homogenization system is used to homogenize beams of different wavelengths to form homogenized white light.

[0072] The above multiple light sources are respectively: a red laser 11 with a central wavelength of 650nm, a green laser 12 with a central wavelength of 532nm, and a blue laser 13 with a central wavelength of 450nm.

[0073] The above-mentioned homogenization system adopts a diffractive optical element 14 with surface phase information as shown in FIG. Use MATLA software to simulate the square homogenization and circular homogenization effects of the diffractive optical element 14, and obtain the simulation effect diagrams shown in Figure 6 (a) and Figure 6 (b), from Figure 6 (a) and F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com