Preparation method for positive non-magnetic toner

A non-magnetic toner, positively charged technology, applied in the direction of developer, electrography, optics, etc., can solve the problems of restricted user use, blackboard trailing, OPC ghosting, etc., and achieve good printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

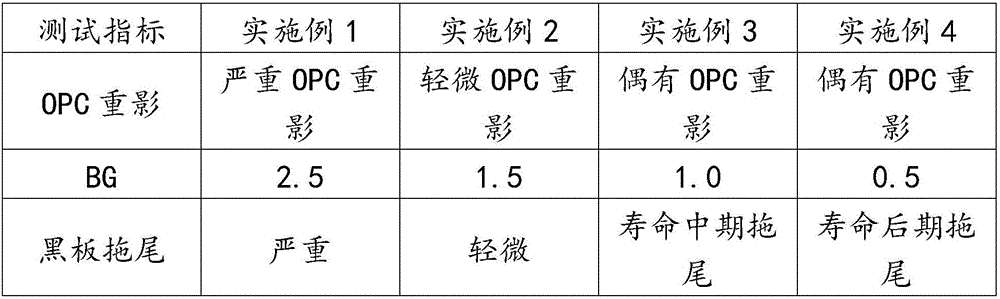

[0013] The positively charged non-magnetic toner of the present invention includes a toner masterbatch and additives, the toner masterbatch includes a styrene-acrylic resin, a release agent, a colorant and a charge control agent, and the additives include silicon dioxide, barium titanate and polymethyl Methyl acrylate, the inventor prepared 4 groups of positively charged non-magnetic toners by adjusting the formula, see Table 1 for the content of each component.

[0014] Table 1

[0015]

[0016] Among them, the particle diameter of fine particle silica is between 7 nanometers and 20 nanometers, the particle diameter of large particle silica is between 40 nanometers and 200 nanometers, and the surfaces of fine particle silica and large particle silica are uniform. Hydrophobic treatment. In the present invention, except carbon black, the colorant can also use cyanine black, ferrite, aniline black, etc., and the wax used in the release agent can be paraffin wax, low molecula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com