Method for improving gain of microchannel plate

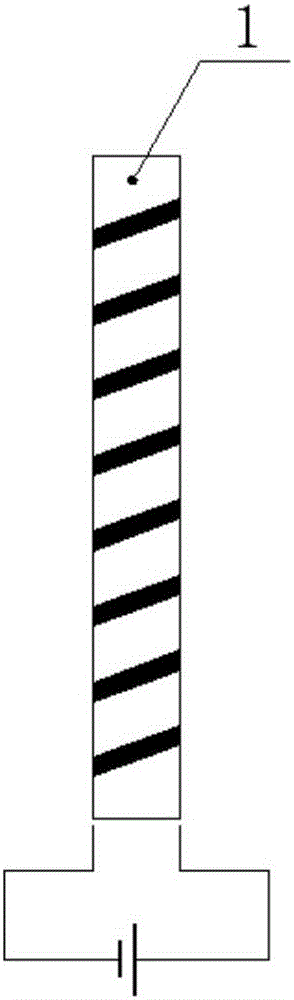

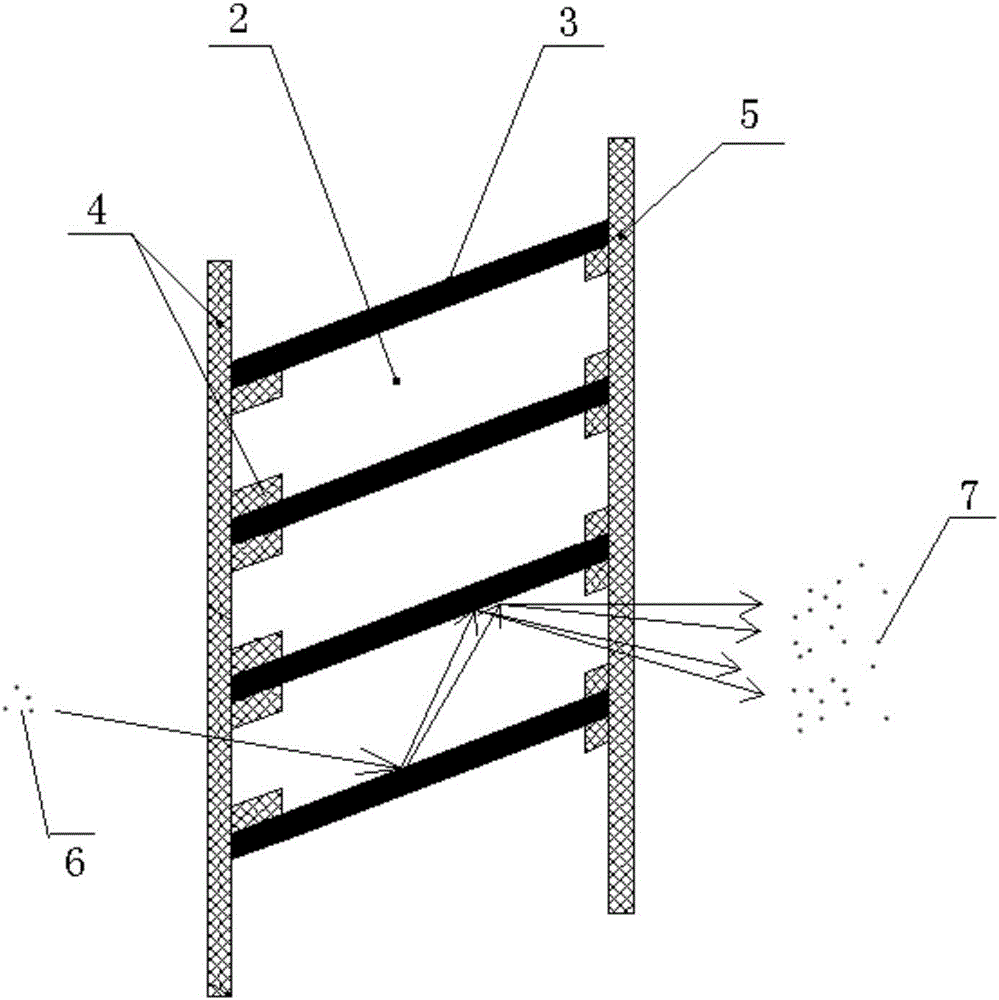

A technology of microchannel plate and dielectric film layer, which is applied in the direction of multiple dynode electrode devices, dynodes, electron multiplier tubes, etc., to achieve the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

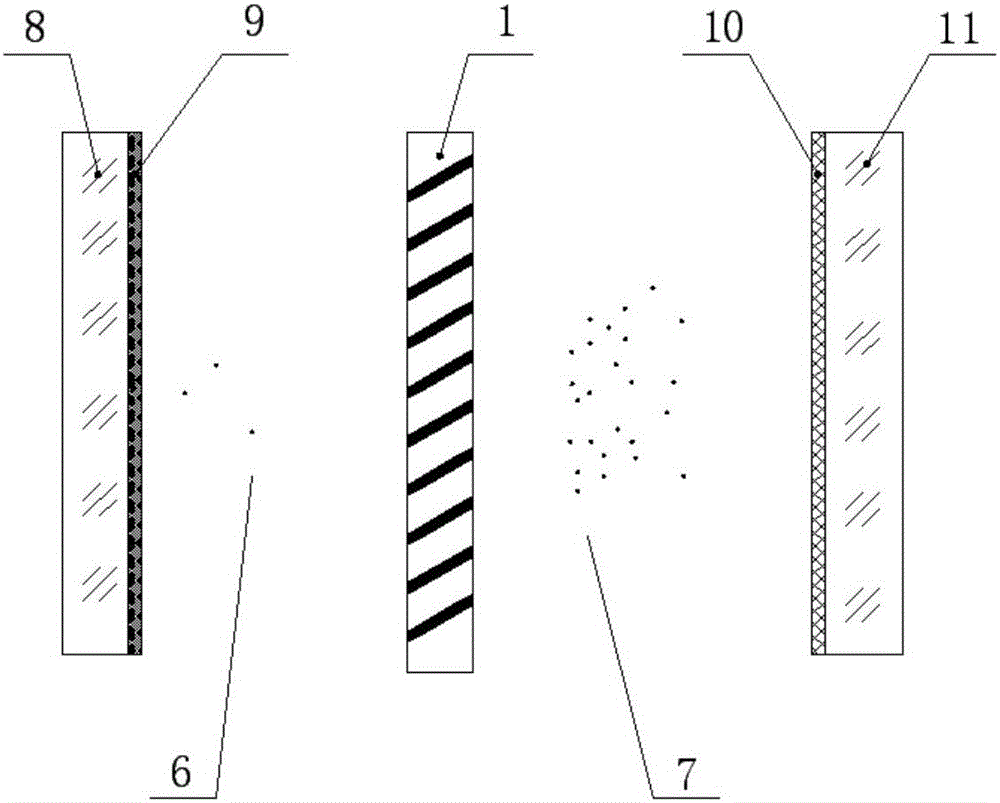

[0024] Put the MCP with a diameter of Φ25mm and a channel diameter of 6 μm into the MCP coating fixture, and put the coating fixture together with the MCP on the workpiece turntable of the coating machine. The coating machine is the ARES710 coating machine of LEYBOLD OPTICS Company.

[0025] Put a certain amount of silica particles in the crucible of the coating machine. The manufacturer of silica is UMICORE Company, the brand is 0481269, the particle size is 0.2-0.7mm, and the purity is 99.99%.

[0026] Close the coater door. Set the parameters of the coating machine as follows: start the vacuum pumping system of the coating machine. When the vacuum degree of the coating machine reaches 4×10 -5 After lifting, start to heat the turntable of the coating machine, the temperature is set to 120° C., the heating time is 25 minutes, and the holding time is 15 minutes.

[0027] After the heating is over, start the coating program. The coating procedure is basically the same as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com