Ceramic coating diaphragm, preparation method thereof and application

A technology of ceramic coating and diaphragm, applied in nanotechnology, nanotechnology, electrical components, etc. for materials and surface science, to achieve good ionic conductivity and mechanical properties, strong operability, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

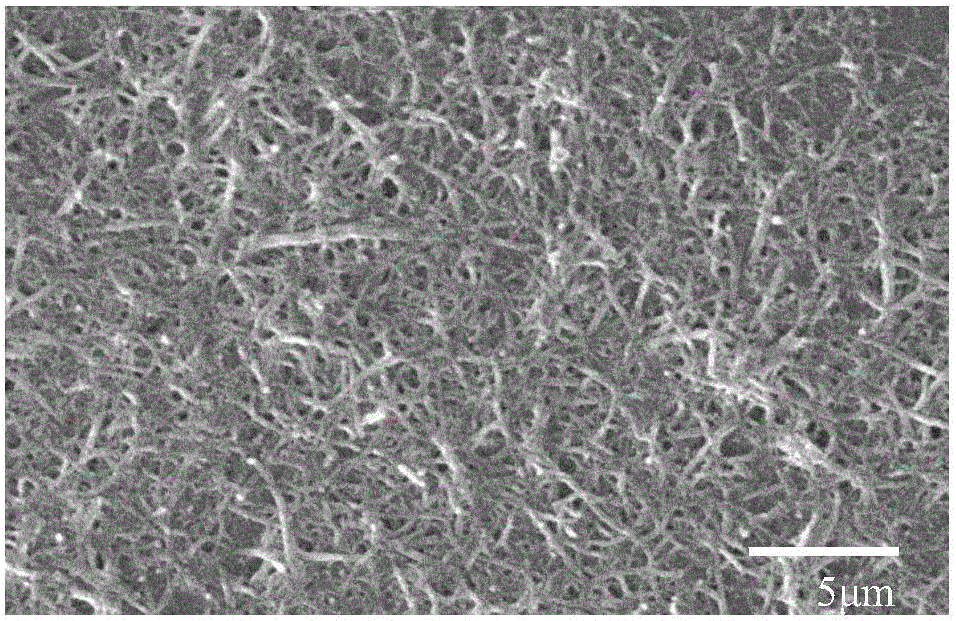

[0039] BN nanowires with a diameter of 10nm and a length of 1-2μm are used as powder, and polymethyl methacrylate is used as a binder to disperse in acetone. One-sided coating was carried out on the separator, and it was dried under vacuum at room temperature. The scanning electron micrographs of the obtained ceramic separator are as follows: figure 1 As shown, it can be seen from the figure that the BN nanowires are evenly coated on the surface of the polypropylene microporous membrane.

Embodiment 2

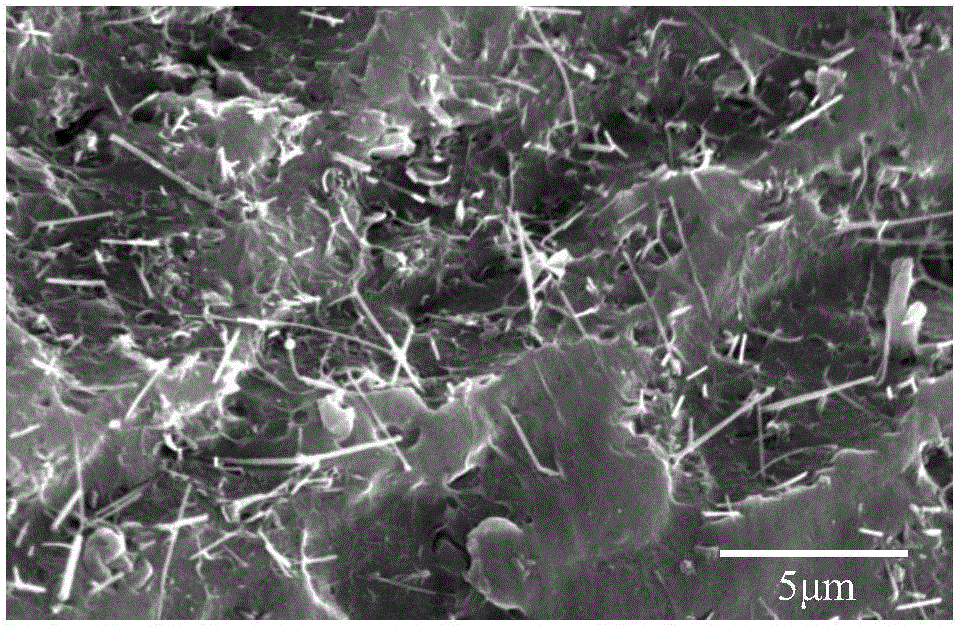

[0041] BN nanotubes with a diameter of 5nm and a length of 10μm are used as powder, and polyvinylidene fluoride is used as a binder to disperse in N-methylpyrrolidone. The speed of min is double-sided coating on the polyethylene diaphragm, and the ceramic diaphragm is obtained after drying.

Embodiment 3

[0043] Nanoparticles with a particle size of 50nm are used as powder, and polyvinylidene fluoride is used as a binder to disperse in dimethylformamide. After dispersing for 5 hours under mechanical stirring conditions, the coating machine is coated with a GTB780 at a speed of 2m / min. Double-sided coating is carried out on the vinylidene fluoride-hexafluoropropylene copolymer membrane, and a ceramic diaphragm is obtained after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com