Negative electrode paste of battery and preparation method of negative electrode paste

A battery anode and slurry technology, applied in the field of energy chemistry, can solve the problems of uneven dispersion of slurry, large amount of surfactant added, easy sedimentation, etc., to improve cycle stability, reduce production costs, and achieve stable chemical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Preparation of battery negative electrode sheet

[0038] The slurry was coated on the copper foil with an automatic coating machine, and the distance between the scrapers was adjusted. After coating, the total thickness of the negative electrode sheet of the battery was 160 μm, and it was rolled by a tablet press. After compaction, the thickness was 120 μm, and the compaction density was 1.5.

[0039] Yield statistics

[0040] For each slurry sample, 200 battery negative electrode sheets are prepared at the same time. The finished product is flat, no cracks, and no exposed copper foil. The percentage of the finished product to the total number of 200 electrode sheets is the yield.

[0041] Preparation of battery

[0042] The lithium iron phosphate material is used as the positive electrode, and the 1mol / L lithium hexafluorophosphate solution is used as the electrolyte; the prepared battery negative electrode sheet, separator, and negative electrode sheet are sequential...

Embodiment 1

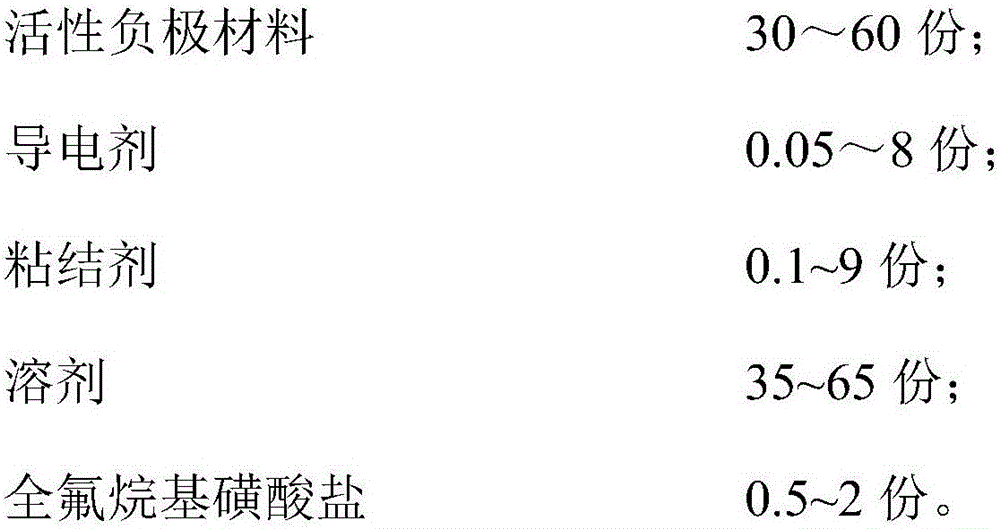

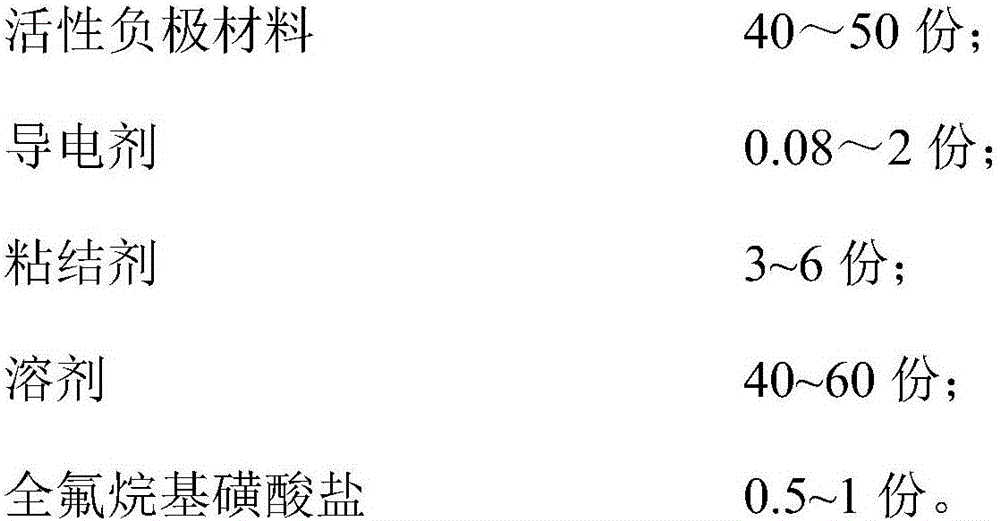

[0046] 1) Add the following components in parts by mass to a high-speed mixer and stir for 3 minutes at 2000r / s to obtain a premixed slurry:

[0047]

[0048]

[0049] 2) Pour the premixed slurry into a high-speed disperser and disperse for 30 minutes at 2000r / min. The slurry collected from the dispersion port is the battery negative electrode slurry.

[0050] The viscosity of the obtained battery negative electrode slurry was 6000mps, and there was no sedimentation phenomenon after standing for 48 hours. The negative electrode sheet prepared with the obtained battery negative electrode slurry had no "concave points" and "convex points", and the yield rate was 99.5%. The obtained battery maintains 95%, 92%, 90%, and 85% of the initial capacity after 100 cycles at 0.1C, 1C, 2C, and 5C, respectively.

Embodiment 2

[0054] The only difference from Example 1 is that LA133 is replaced by SBR and CMC in different proportions, the optimum battery negative electrode slurry viscosity is 6000mps, and there is still no sedimentation after standing for 48 hours, and the negative electrode is prepared with the obtained battery negative electrode slurry The chip has no "concave point" and "convex point", and the yield rate is 95%. The obtained battery maintains 91%, 90%, 70% and 60% of the initial capacity after 100 cycles at 0.1C, 1C, 2C and 5C, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com