High-stability ordered mesoporous carbon loaded Fenton catalyst, and preparation method and application thereof

A high-stability, mesoporous carbon technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as plugging pores, achieve good degradation effect, wide range of pH use, and active high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Mix 1 g of ordered mesoporous carbon with 30 mL of 1M ammonium persulfate, heat and condense to reflux at 60 °C for 24 h, filter the reaction solution after cooling, wash the reaction product with deionized water, and dry in vacuum for 12 h to obtain the ordered wet oxidation treatment. mesoporous carbon.

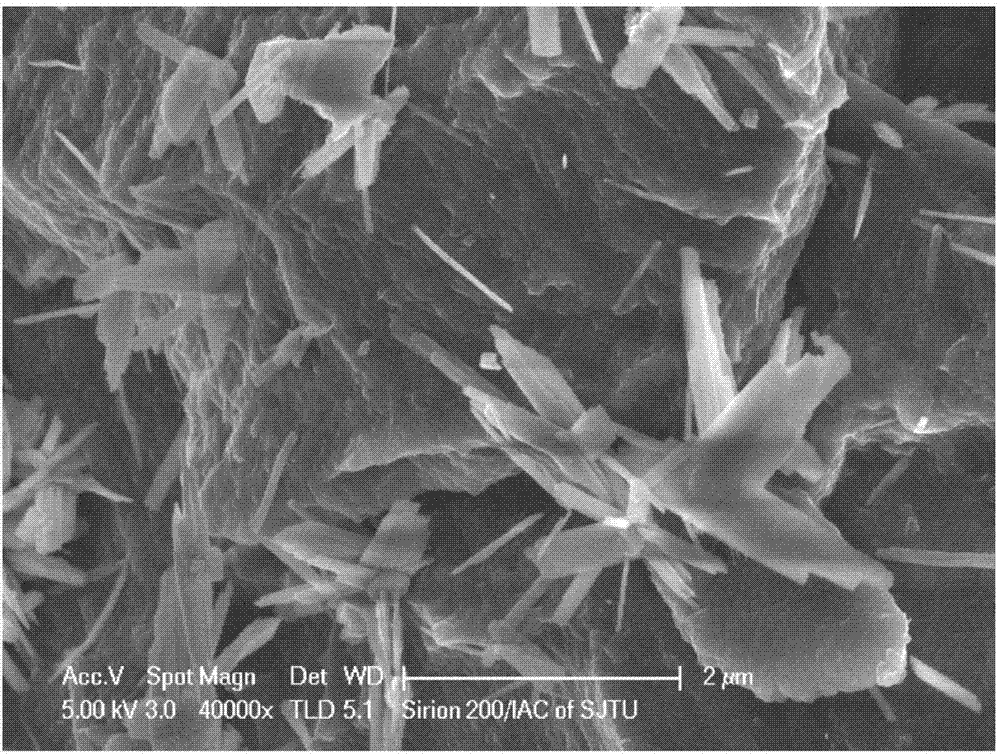

[0038] Take 0.1 g of ordered mesoporous carbon after wet oxidation treatment and add it into 25 mL of 0.14 M ferric nitrate solution, stir overnight, wash and filter with deionized water. Transfer the washed product to a beaker, add 5 mL of deionized water, then quickly add 9 mL of 5M NaOH, and finally add 86 mL of deionized water. The reaction solution was transferred to a 100mL polytetrafluoroethylene reactor, and heated at 70°C for 12h. After cooling, filter the reaction liquid, wash the reaction product with deionized water and absolute ethanol several times, and obtain α-FeOOH / MesoC-12 after vacuum drying. figure 1 As shown, the X-ray diffraction pattern is sh...

Embodiment 2

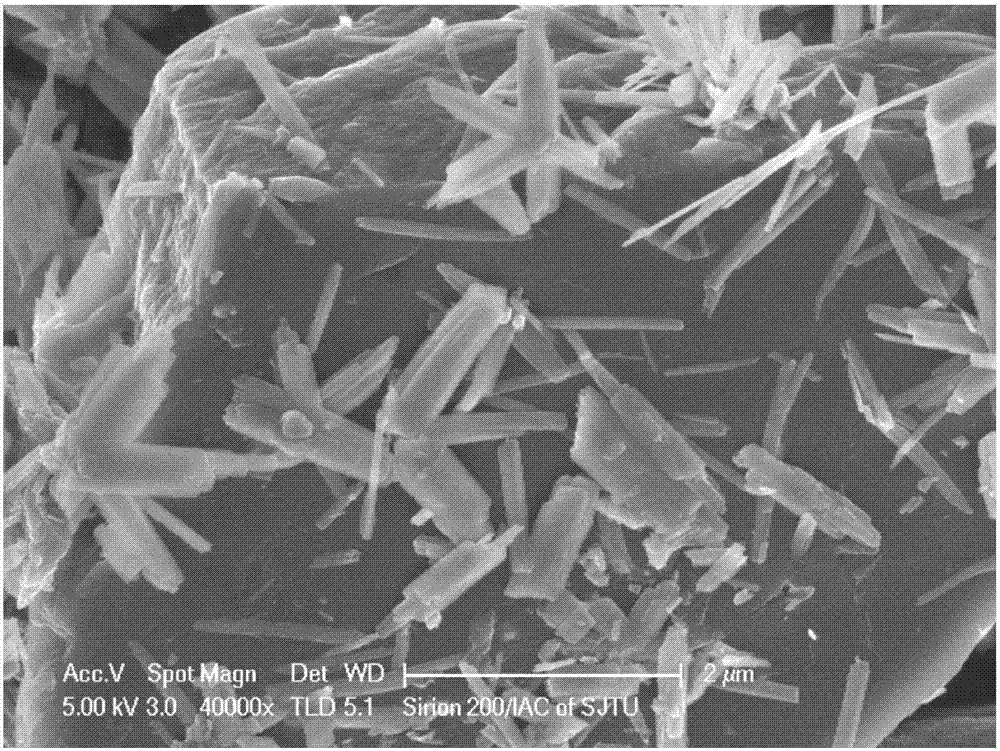

[0045] This example is a modification example of Example 1, and the technical scheme is the same as that of Example 1, except that the hydrothermal time at 70° C. is 36 hours, and the obtained product is α-FeOOH / MesoC-36. Its scanning electron microscope picture is as follows figure 2 As shown, the X-ray diffraction pattern is shown in Figure 4 shown.

[0046] Add 30mgα-FeOOH / MesoC-36 to 60mL 100mg / L rhodamine B solution, adjust the pH to 7, stir for 30 minutes to reach adsorption equilibrium, add 180μL H 2 o 2 , the decolorization effect of Rhodamine B reached 93% after 90 minutes.

[0047] Add 10 mgα-FeOOH / MesoC-36 to 20 mL of 100 mg / L phenol solution, adjust the pH to 5, stir for 30 minutes to reach adsorption equilibrium, then add 60 μL H 2 o 2 , producing 9.4 μmol CO in 2 h 2 .

Embodiment 3

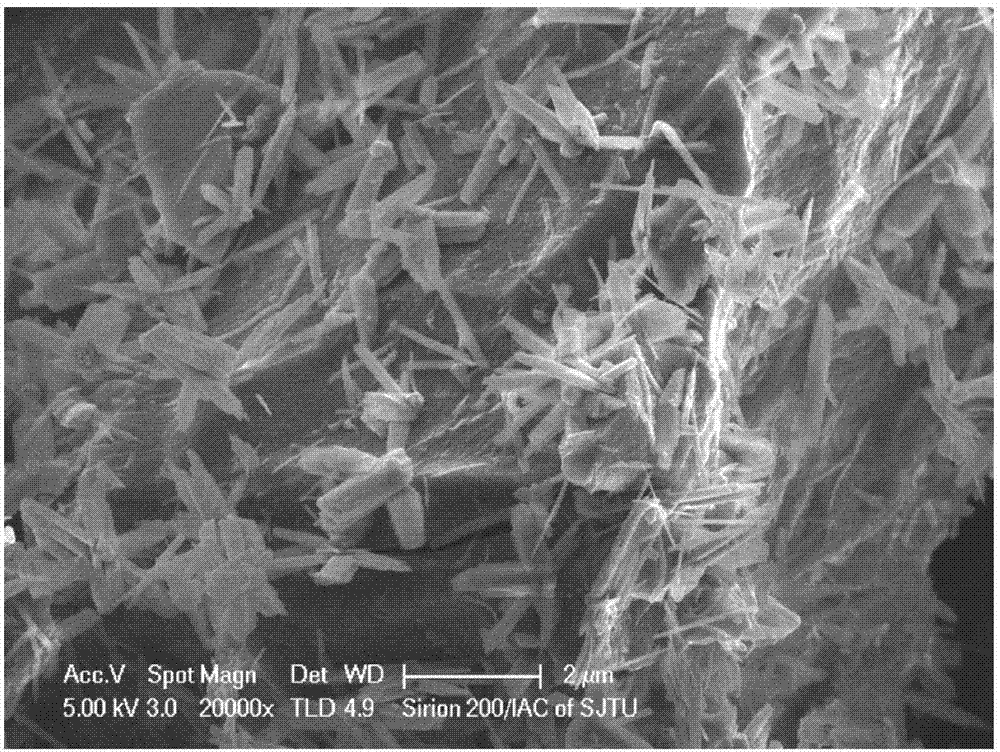

[0049] This example is a modification example of Example 1, and the technical scheme is the same as that of Example 1, except that the hydrothermal time at 70° C. is 60 h, and the obtained product is α-FeOOH / MesoC-60. Its scanning electron microscope picture is as follows image 3 As shown, the X-ray diffraction pattern is shown in Figure 4 shown.

[0050] Add 30mgα-FeOOH / MesoC-60 to 60mL 100mg / L rhodamine B solution, adjust the pH to 7, stir for 30 minutes to reach adsorption equilibrium, add 180μL H 2 o 2 , the decolorization effect of Rhodamine B reached 94% after 90 minutes.

[0051] Add 10 mgα-FeOOH / MesoC-60 to 20 mL of 100 mg / L phenol solution, adjust the pH to 5, stir for 30 minutes to reach adsorption equilibrium, add 60 μL H 2 o 2 , producing 5.5 μmol CO in 2 h 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com