Claw provided with novel abrasion-resisting layer structure and manufacturing method thereof

A manufacturing method and wear-resistant layer technology, applied in the field of laser additive manufacturing, can solve problems such as no engineering application value, low product qualification rate, poor process stability, etc., and achieve uniform and controllable hardness, good mechanical properties, and high production yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

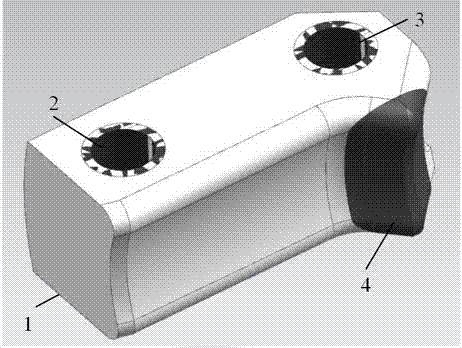

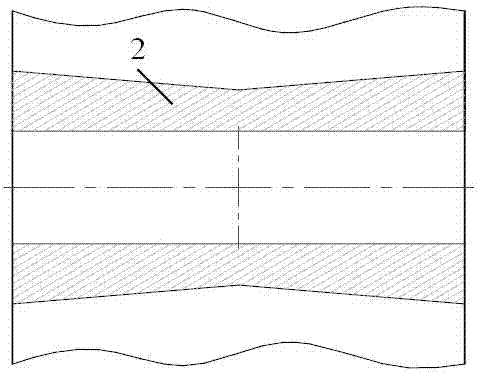

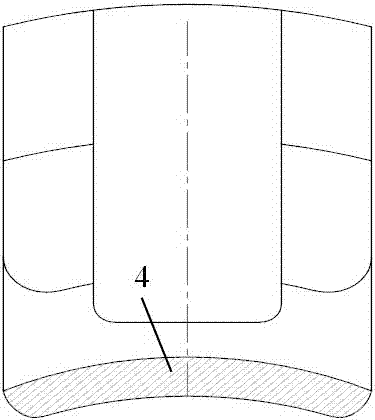

[0057]The manufacturing method of the oxyacetylene surfacing welding hook is: use 00Cr18Ni9N nitrogen-controlled austenitic stainless steel forging rod to machine into the hook base 1, and process the pin hole on the base; the lower pin hole 2 is processed into a symmetrical cone with a certain inclination angle. shaped holes, such as figure 2 Shown; Hook tooth face milling produces groove surface, such as image 3 As shown; Then use Stellite 6 cobalt-based alloy welding wire to carry out oxyacetylene surfacing welding pin hole wear-resistant layers 2 and 3, and surfacing hook tooth 4 on the hook tooth surface; then anneal the blank, and finally machine the finished product. One of the difficulties of this process is the surfacing of the wear-resistant layer in the pin hole. The pin hole of the hook claw is a small diameter deep hole, in which the welding is mainly carried out by manual operation. Although Stellite 6 cobalt-based alloy has good wear resistance, it is a resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com