Method for preparing wheat germ polypeptides containing high-affinity calcium through electron beam irradiation in combination with enzyme method as well as separation and purification

A technology of electron beam irradiation and enzymatic separation, which is applied in the direction of peptides and fermentation, can solve the problems of limiting the comprehensive utilization of wheat germ protein, poor solubility, environmental pollution, etc., to shorten the time of enzymatic hydrolysis, improve the degree of hydrolysis, The effect of increasing the chelation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Extraction of wheat germ protein isolate: defatted wheat germ powder (purchased from Anyang Mantianxue Co., Ltd., Henan Province) was dispersed in deionized water at a material-to-liquid ratio of 1:10 (w / v), and the pH of the dispersion was kept constant at pH9. 5. Stir at a constant temperature of 40°C for 2 hours, centrifuge at 5000rpm for 10 minutes to obtain a supernatant, adjust the supernatant to pH 4.0 to precipitate protein, wash the protein twice with water and adjust the pH to neutral, freeze-dry to obtain wheat germ protein isolate.

[0024] (2) Wheat germ protein isolate powder and deionized water are mixed according to the material-to-liquid ratio of 40% (w / v), and lye is added to form a weakly alkaline suspension (pH8.0), which is sealed in a transparent In a sealed bag, the thickness is controlled at 1-2cm.

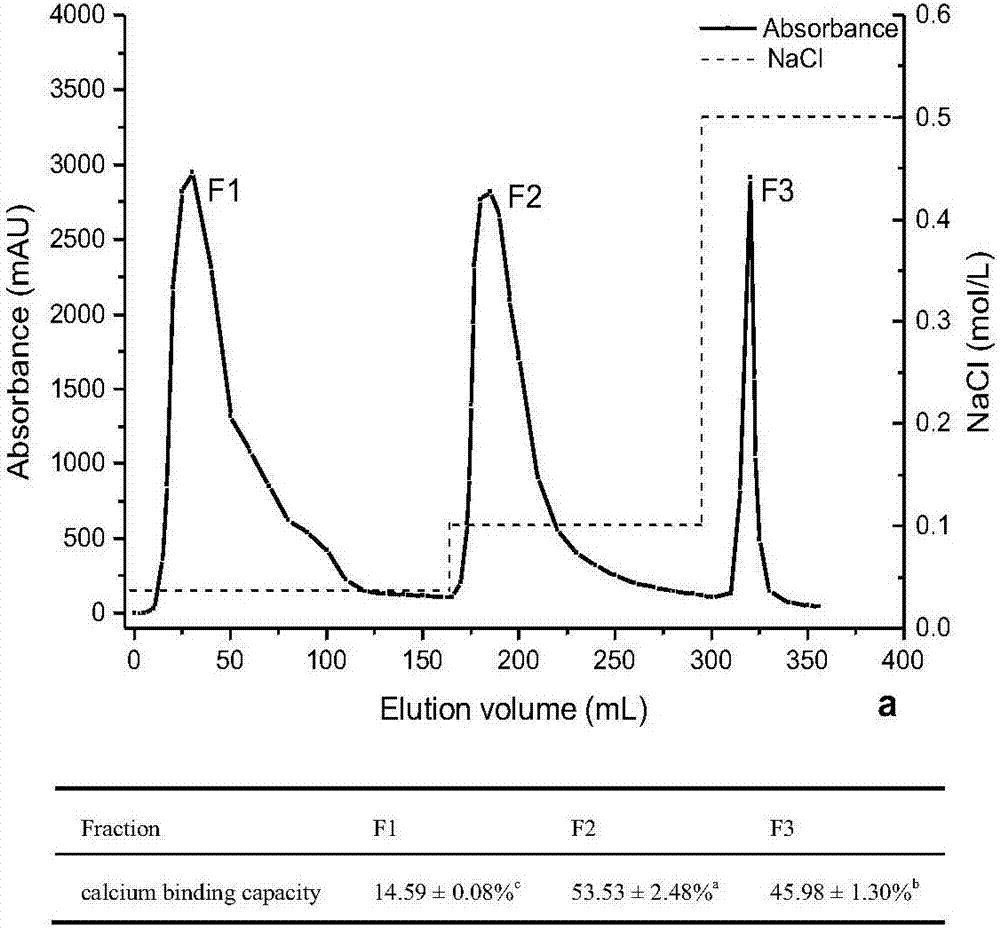

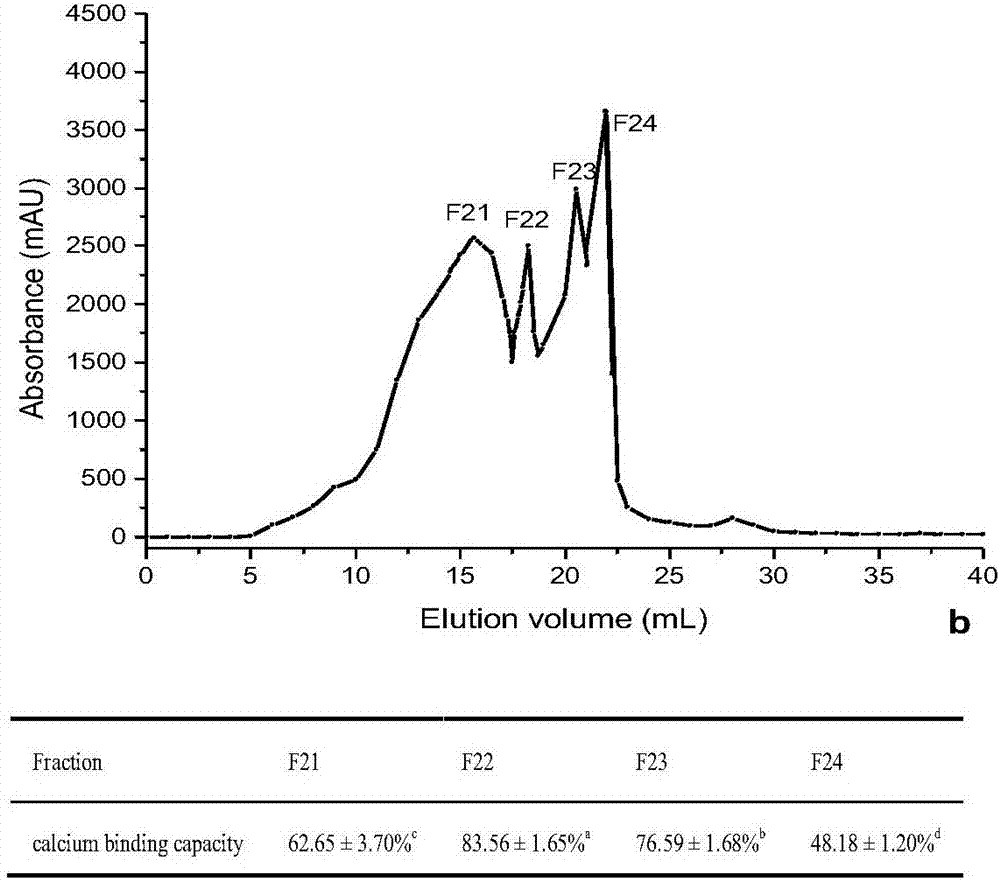

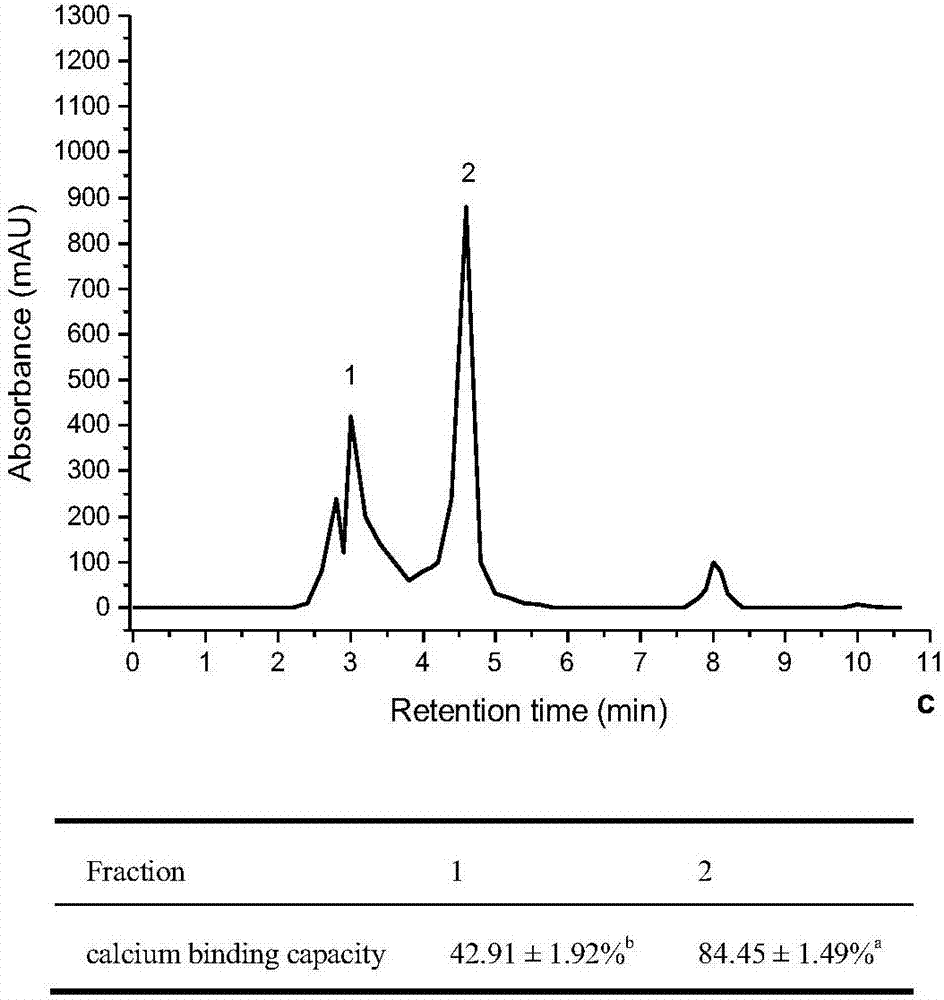

[0025] (3) The protein suspension is placed on the conveyor belt, and irradiated under the electron accelerator, the irradiation dose is 1kGy, a...

Embodiment 2

[0032] (1) Extraction of wheat germ protein isolate: defatted wheat germ powder (purchased from Anyang Mantianxue Co., Ltd., Henan Province) was dispersed in deionized water at a material-to-liquid ratio of 1:10 (w / v), and the pH of the dispersion was kept constant at pH9. 5. Stir at a constant temperature of 40°C for 2 hours, centrifuge at 5000rpm for 10 minutes to obtain a supernatant, adjust the supernatant to pH 4.0 to precipitate protein, wash the protein twice and adjust the pH to neutral, freeze-dry to obtain wheat germ protein isolate.

[0033] (2) Wheat germ protein isolate powder and deionized water are mixed according to the material-to-liquid ratio of 10% (w / v), and lye is added to form a weakly alkaline suspension (pH8.5), which is sealed in a transparent In a sealed bag, the thickness is controlled at 1-2cm.

[0034] (3) The protein suspension is placed on a conveyor belt and irradiated under an electron accelerator with a dose of 5 kGy and an irradiation conditi...

Embodiment 3

[0041] (1) Extraction of wheat germ protein isolate: defatted wheat germ powder (purchased from Anyang Mantianxue Co., Ltd., Henan Province) was dispersed in deionized water at a material-to-liquid ratio of 1:10 (w / v), and the pH of the dispersion was kept constant at pH9. 5. Stir at a constant temperature of 40°C for 2 hours, centrifuge at 5000rpm for 10 minutes to obtain a supernatant, adjust the supernatant to pH 4.0 to precipitate protein, wash the protein twice with water and adjust the pH to neutral, freeze-dry to obtain wheat germ protein isolate.

[0042] (2) Wheat germ protein isolate powder and deionized water are mixed according to the material-to-liquid ratio of 25% (w / v), and lye is added to form a weakly alkaline suspension (pH7.5), which is sealed in a transparent In a sealed bag, the thickness is controlled at 1-2cm.

[0043] (3) The protein suspension is placed on a conveyor belt and irradiated under an electron accelerator with a dose of 10 kGy and an irradia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com