Preparation method of efficient PEI (polyethyleneimine) modified porous adsorption material and application

A porous adsorption material, polyethyleneimine technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., to achieve suitable for large-scale production, simple synthesis process, and conducive to batch processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

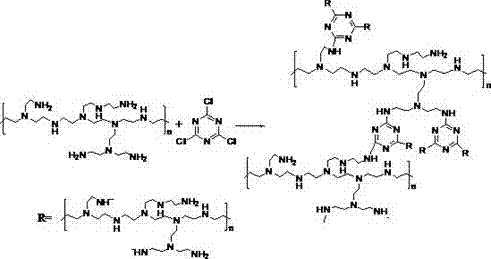

[0017] Preparation of a porous material based on polyethyleneimine (PEI) and cyanuric chloride: 10 g of PEI was added into a 500 mL three-necked flask under heating and reflux reaction conditions, and fully dissolved with tetrahydrofuran. Stir and heat, and when the internal temperature reaches 70°C, start to slowly drop the tetrahydrofuran solution dissolved with cyanuric chloride into the reaction flask, and after the dropwise addition is completed, keep the reaction for 24 hours. After the reaction was completed, the reaction solution was poured into an ice bath to precipitate a crude product. After the crude product was processed several times, it was dried to obtain the product with a yield of 85.5%.

Embodiment 2

[0019]Preparation of a porous material based on polyethyleneimine (PEI) and biphenyl benzyl chloride: 10 g of PEI was added to a 500 mL three-necked flask under heating and reflux reaction conditions, and fully dissolved with tetrahydrofuran. Stir and heat, and when the internal temperature reaches 70°C, slowly add the tetrahydrofuran solution dissolved in biphenyl dibenzyl chloride into the reaction flask dropwise, after the dropwise addition is completed, keep the reaction for 24 hours. After the reaction was completed, the reaction solution was poured into an ice bath to precipitate a crude product. After the crude product was processed several times, it was dried to obtain the product with a yield of 65%.

Embodiment 3

[0021] According to the product of embodiment 1, it is compared to Cu 2+ Carry out adsorption experiment: Weigh 1g of adsorbent in a centrifuge tube, and add 100ml of 100 mg / L Cu 2+ The original solution was stirred at room temperature, and after adsorption for 0.5 h, the atomic absorption test was performed on the clear solution. The adsorption capacity is: 1 g adsorbent adsorbs 48.04 mg Cu 2+ .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com