A kind of titanium oxide supported subnano rhodium catalyst and its preparation and application

A rhodium catalyst, catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as unsatisfactory, achieve good low-temperature startability, excellent Effect of low-temperature catalytic oxidation performance and high decomposition activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

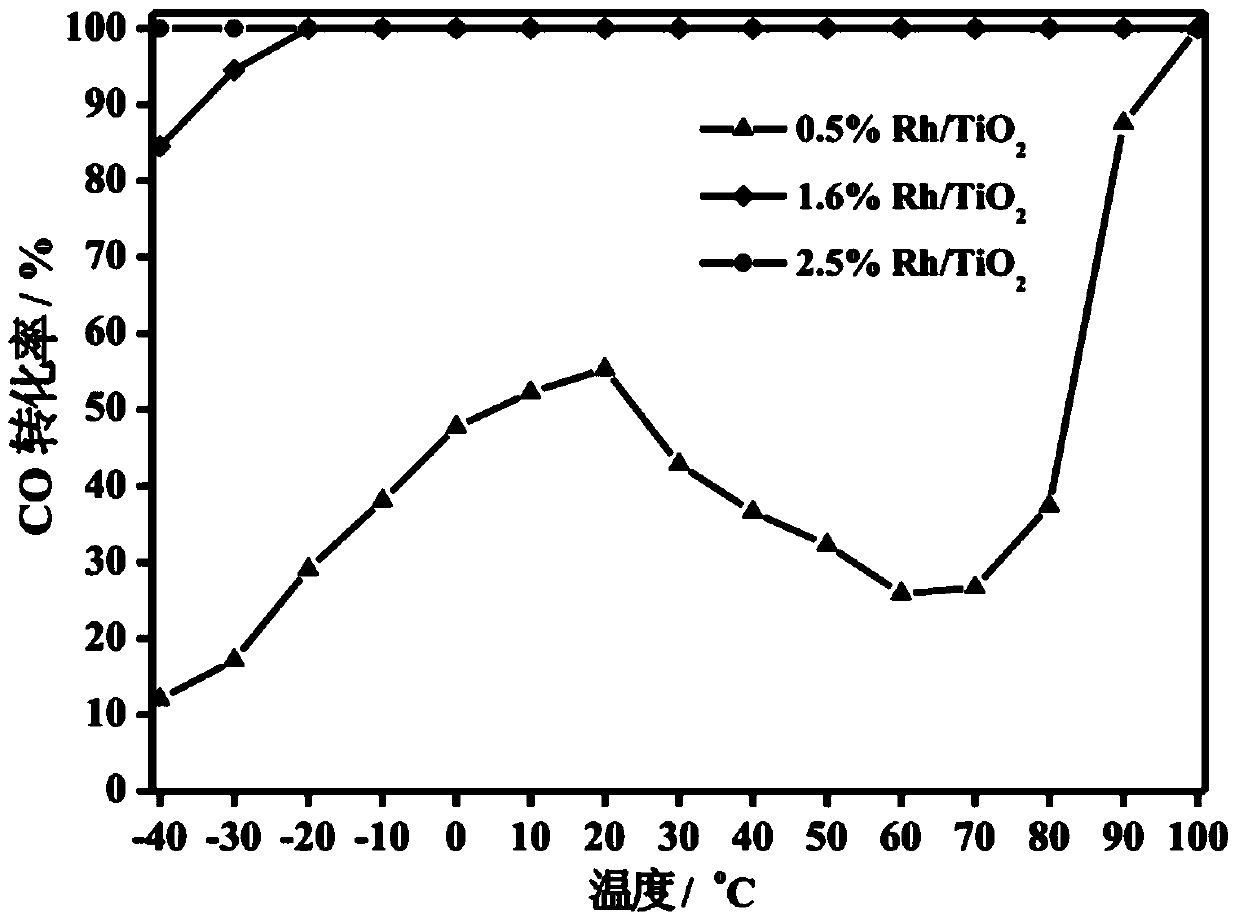

Embodiment 1

[0031] Ultrasonically disperse 1 g of mixed crystal phase titanium oxide (Degussa P25, 80% anatase and 20% rutile, the same below) carrier in 100 mL deionized water to form a suspension; take 8 mL of 0.68 mg / mL chloride Rhodium solution, add 100mL deionized water to stir and dilute, and add dropwise to the carrier suspension under strong stirring, adjust the pH value to 9.6, stir at 80°C for 3h, let stand for 1h, filter, wash with hot water, and oven at 80°C Dry in medium for 12h. After drying, the catalyst was calcined at 400°C in air for 4h to obtain 0.5wt.%Rh / TiO 2 catalyst.

Embodiment 2

[0033] Ultrasonic disperse 1g of P25 carrier in 100mL of deionized water to form a suspension; take 28mL of 0.68mg / mL rhodium chloride solution, add 100mL of deionized water to stir and dilute, and add drop by drop to the carrier suspension under strong stirring , adjust the pH value to 9.8, stir at 80°C for 3h, let stand for 1h, filter, wash with hot water, and dry in an oven at 80°C for 12h. After drying, the catalyst was calcined at 400°C in air for 4h to obtain 1.6wt.%Rh / TiO 2 catalyst. Example 3:

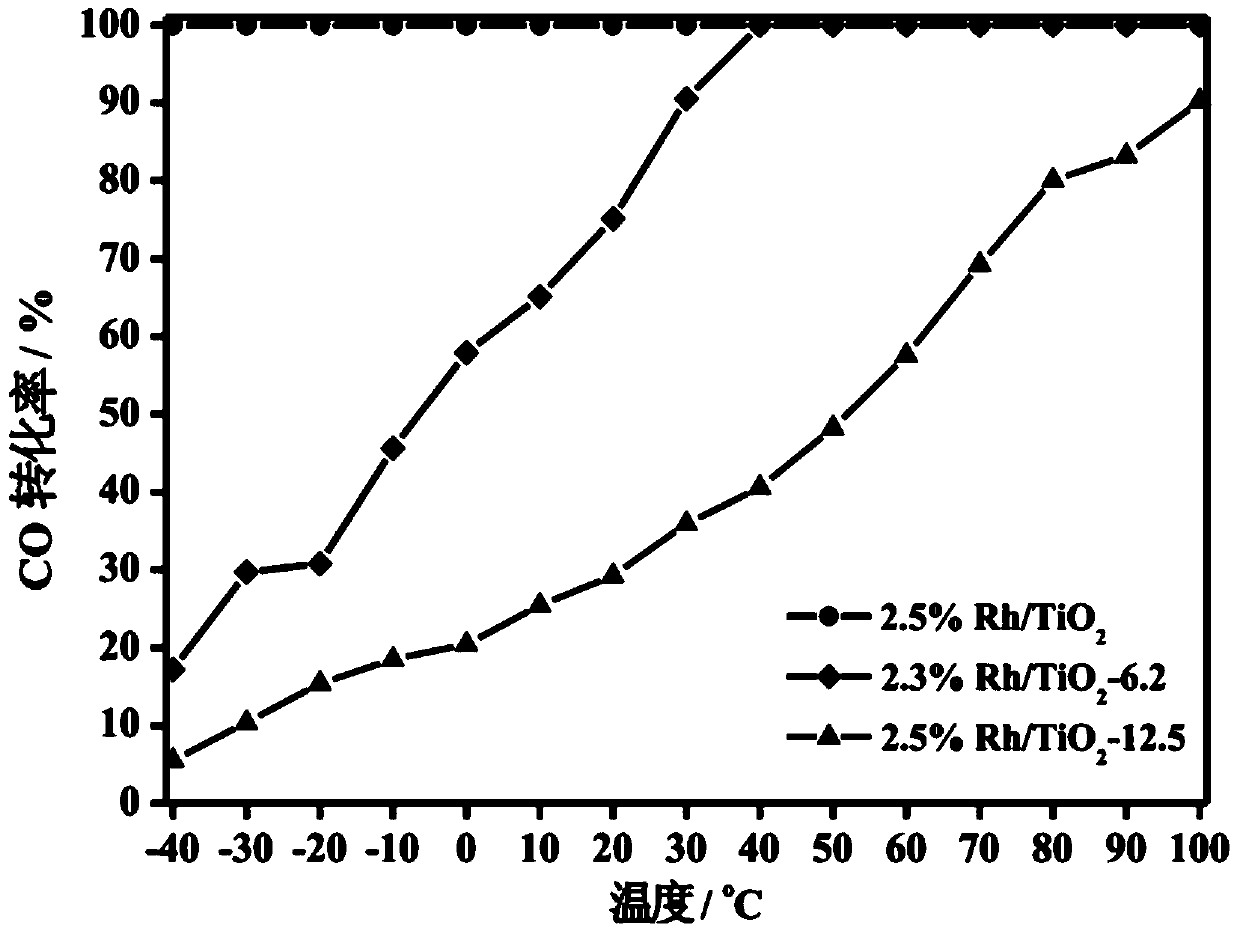

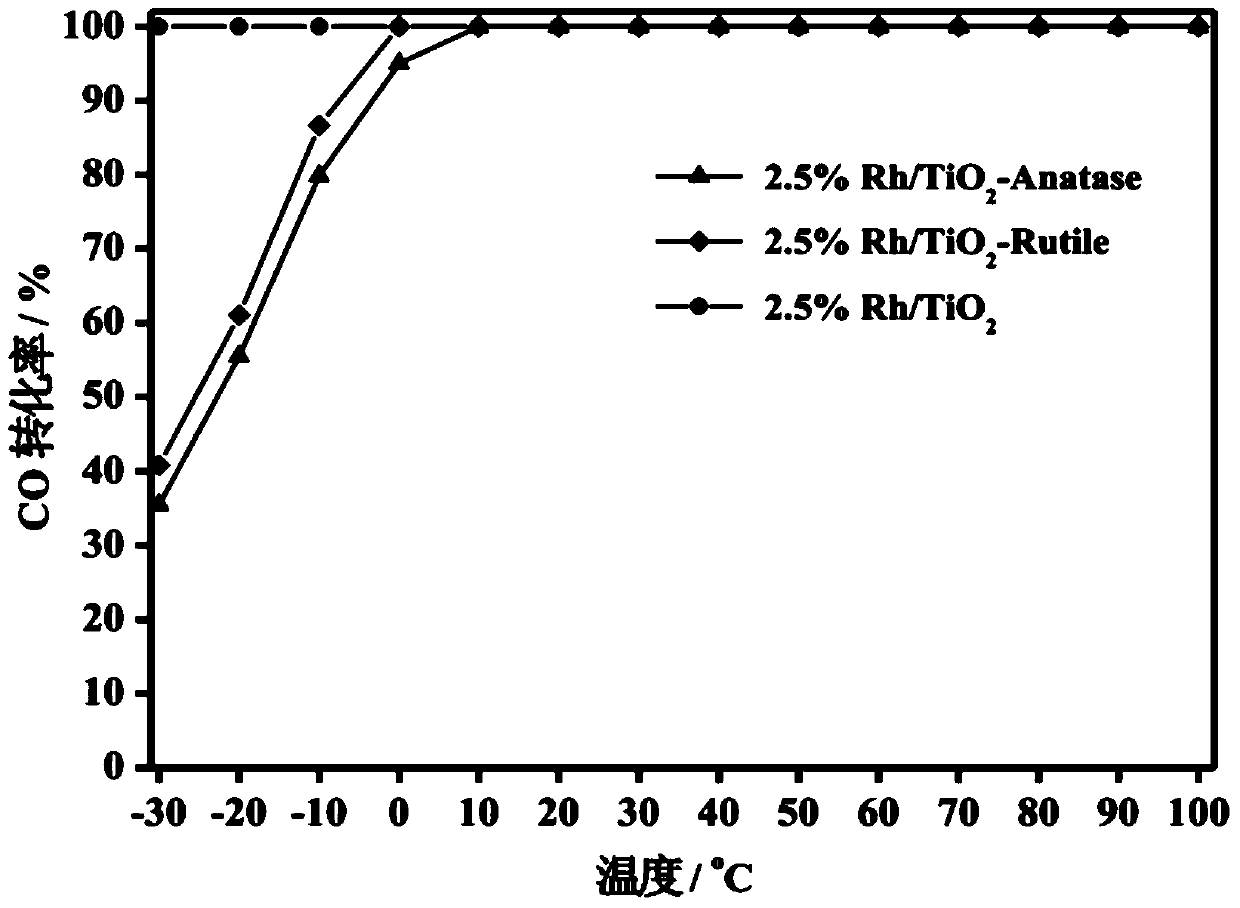

Embodiment 3

[0034] Ultrasonic disperse 1g of P25 carrier in 100mL of deionized water to form a suspension; take 40mL of 0.68mg / mL rhodium chloride solution, add 100mL of deionized water to stir and dilute, and add dropwise to the carrier suspension under strong stirring , adjust the pH value to 9.4, stir at 80°C for 3h, let stand for 1h, filter, wash with hot water, and dry in an oven at 80°C for 12h. After drying, the catalyst was calcined at 400°C in air for 4h to obtain 2.5wt.%Rh / TiO 2 catalyst. Example 4:

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com