Method for brazing stainless steel and cemented carbide through gradient material method

A technology of cemented carbide and gradient materials, applied in the direction of welding medium, welding/cutting medium/material, welding equipment, etc., can solve the problems of large residual stress in welding joints, etc., to ensure welding quality, reduce residual stress, and ensure corrosion resistance The effect of sex and intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

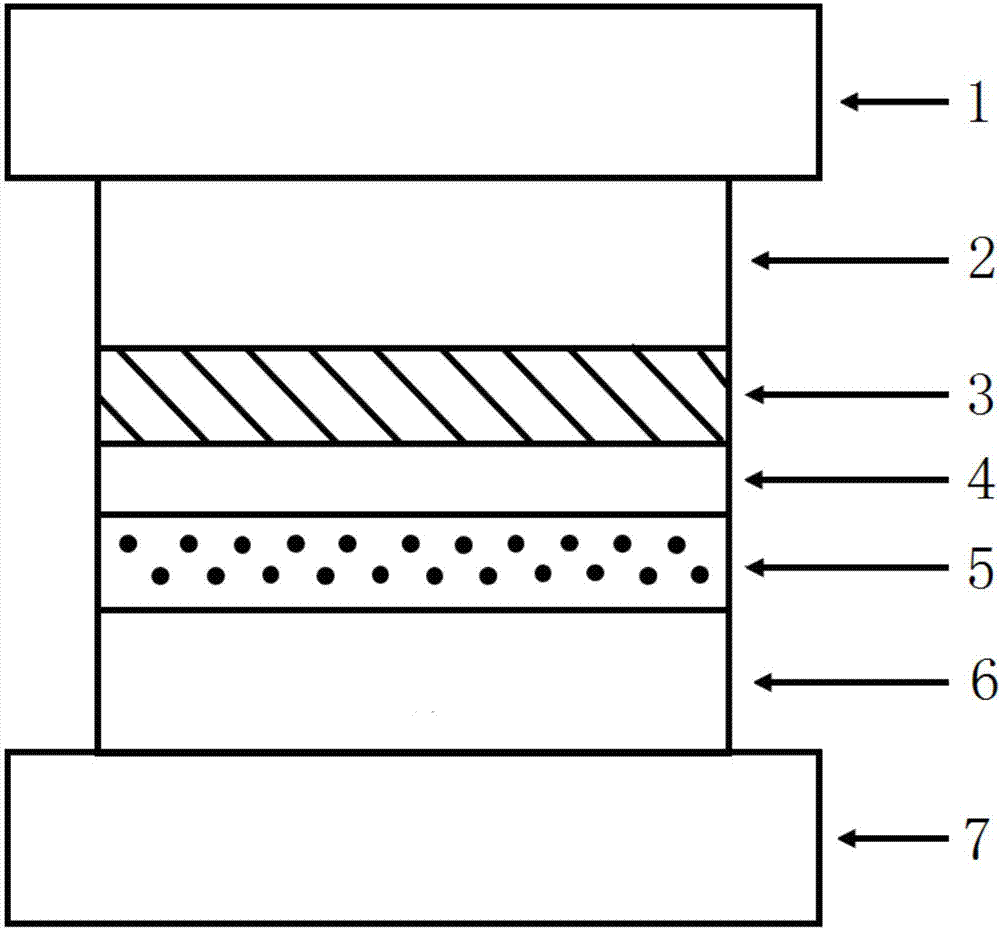

[0028] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment is a method for brazing stainless steel and cemented carbide by gradient material method. The method is specifically carried out according to the following steps:

[0029] 1. Add 10-30wt% reinforcement particles to the solder powder to obtain composite solder powder with high reinforcement content, and add 1-10 wt% reinforcement particles to the solder powder to obtain composite solder powder with low reinforcement content powder;

[0030] 2. Put the composite solder powder with high reinforcement content and the composite solder powder with low reinforcement content into the stainless steel mixing tank respectively, and stir for 1 to 3 hours at a speed of 250 to 300 rpm;

[0031] 3. Put the composite solder powder with high reinforcement content and the composite solder powder with low reinforcement content obtained in step 2 respectively into a mortar, and add 1 to 10 wt% liq...

specific Embodiment approach 2

[0041] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the solder powder in step 1 is Ni-Cr-B-Si alloy powder, Ni-Cr-B-Si-Mo alloy powder or Ni-Cr - B-Si-Mo-Cu alloy powder. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the reinforcement particles in Step 1 are SiC particles, WC particles or Cr particles. 3 C 2 particles. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com