Red mud lightweight thermal-insulation ceramic bricks as well as application and preparation method thereof

A technology for ceramic bricks and red mud, which is applied in the field of high-volume Bayer process red mud light-weight thermal insulation ceramic bricks and their preparation fields, can solve the problems of insulation material gap, red mud stacking pollution, difficulty in large-scale treatment, etc., and achieves the cost of raw materials. Low, good working performance, easy cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method for preparing light-weight thermal insulation ceramic tiles with a large amount of red mud, including the following steps:

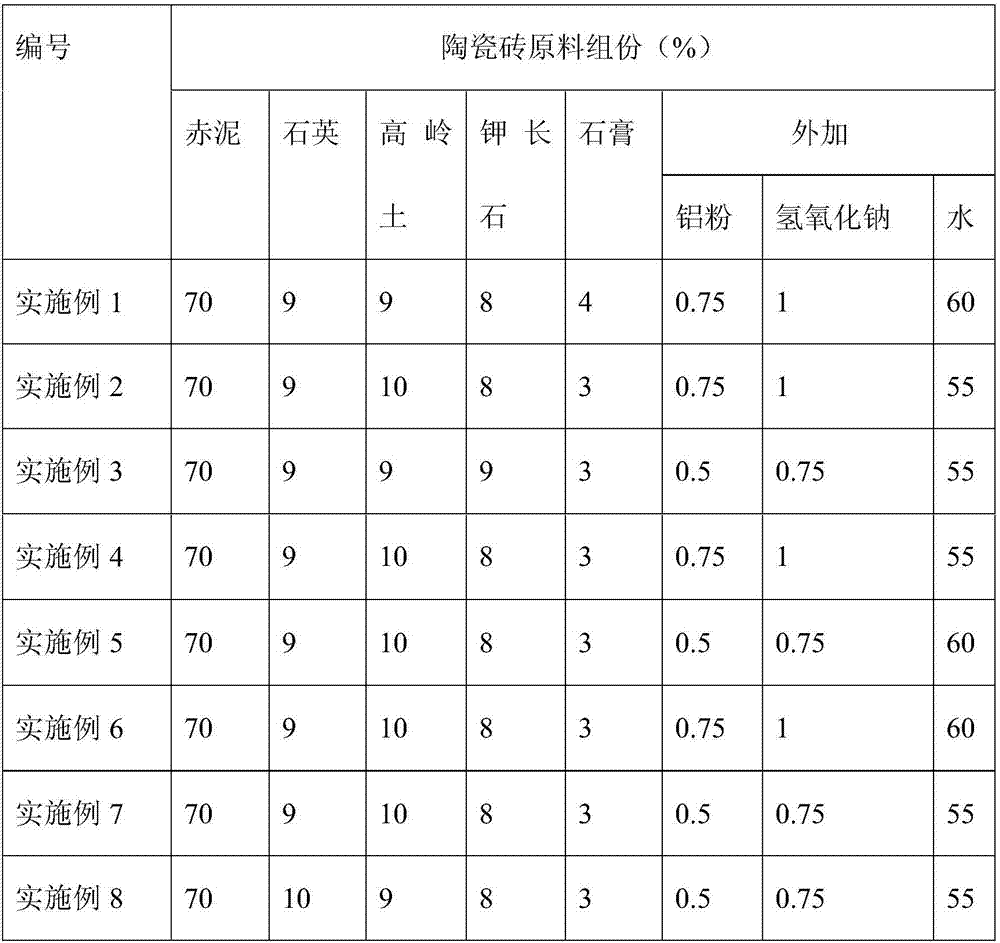

[0040] 1) Weigh the red mud, quartz, potash feldspar, kaolin, gypsum, aluminum powder, sodium hydroxide and water according to the weight percentage of the ceramic tile raw materials;

[0041] 2) The red mud, quartz, potash feldspar, and kaolin weighed in step 1) are mixed and stirred uniformly to obtain a mixture;

[0042] 3) Add 25% of the total amount of water weighed in step 1) to the weighed gypsum and aluminum powder, mix and stir to obtain a mixed solution;

[0043] 4) Add the amount of water weighed in step 1) to the remaining amount of water after use in step 3) to the solid sodium hydroxide weighed in step 1), and stir until the sodium hydroxide is completely dissolved to obtain a sodium hydroxide solution;

[0044] 5) Add the sodium hydroxide solution in step 4) to the mixture in step 2) and stir evenly to obtain a slurry;

[...

Embodiment 2

[0048] A preparation method for preparing light-weight thermal insulation ceramic tiles with a large amount of red mud, including the following steps:

[0049] 1) Weigh the red mud, quartz, potash feldspar, kaolin, gypsum, aluminum powder, sodium hydroxide and water according to the weight percentage of the ceramic tile raw materials;

[0050] 2) The red mud, quartz, potash feldspar, and kaolin weighed in step 1) are mixed and stirred uniformly to obtain a mixture;

[0051] 3) Add 20% of the total amount of water weighed in step 1) to the weighed gypsum and aluminum powder, mix and stir to obtain a mixed solution;

[0052] 4) Add the amount of water weighed in step 1) to the remaining amount of water after use in step 3) to the solid sodium hydroxide weighed in step 1), and stir until the sodium hydroxide is completely dissolved to obtain a sodium hydroxide solution;

[0053] 5) Add the sodium hydroxide solution in step 4) to the mixture in step 2) and stir evenly to obtain a slurry;

[...

Embodiment 3

[0057] A preparation method for preparing light-weight thermal insulation ceramic tiles with a large amount of red mud, including the following steps:

[0058] 1) Weigh the red mud, quartz, potash feldspar, kaolin, gypsum, aluminum powder, sodium hydroxide and water according to the weight percentage of the ceramic tile raw materials;

[0059] 2) The red mud, quartz, potash feldspar, and kaolin weighed in step 1) are mixed and stirred uniformly to obtain a mixture;

[0060] 3) Add 20% of the total amount of water weighed in step 1) to the weighed gypsum and aluminum powder, mix and stir to obtain a mixed solution;

[0061] 4) Add the amount of water weighed in step 1) to the remaining amount of water after use in step 3) to the solid sodium hydroxide weighed in step 1), and stir until the sodium hydroxide is completely dissolved to obtain a sodium hydroxide solution;

[0062] 5) Add the sodium hydroxide solution in step 4) to the mixture in step 2) and stir evenly to obtain a slurry;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com