Stealthy coating compatible with laser and infrared and preparation method thereof

A coating, infrared technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of urgent application needs, incompatibility with laser stealth, unsatisfactory effect, etc., and achieve the effect of good stealth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A stealth coating compatible with laser and infrared. The stealth coating compatible with laser and infrared is mainly composed of filler and resin matrix. The filler is a composite filler composed of samarium oxide, lanthanum oxide, flake aluminum powder, and indium tin oxide. ; The resin matrix is polyurethane resin. The composition and the parts by weight of the described stealth coating compatible with laser and infrared are as follows:

[0026]

[0027]

[0028] The flaky aluminum powder described herein is a floating aluminum powder with a particle size of 8-20 um and an average particle size of about 13 um.

[0029] Wherein said organic solvent is a kind of in propylene glycol methyl ether acetate or butyl acetate or acetone.

[0030] The resin described herein is polyurethane resin, which has good adhesiveness, manufacturability and mechanical strength.

[0031] The indium tin oxide mentioned therein is a kind of semiconductor material, which has a low...

Embodiment 2

[0041] Basically the same as Example 1, the difference is that the composition and parts by weight of the stealth coating compatible with laser and infrared are as follows:

[0042]

[0043] The average emissivity of the coating thus prepared is 0.5 in the infrared band 3-5um; the average emissivity in the infrared band 8-14um is 0.6; the reflectance in the 1.06um laser band is 0.15; the reflectance in the 10.6um laser band is 0.15 ;

Embodiment 3

[0045] Basically the same as Example 1, the difference is that the composition and parts by weight of the stealth coating compatible with laser and infrared are as follows:

[0046]

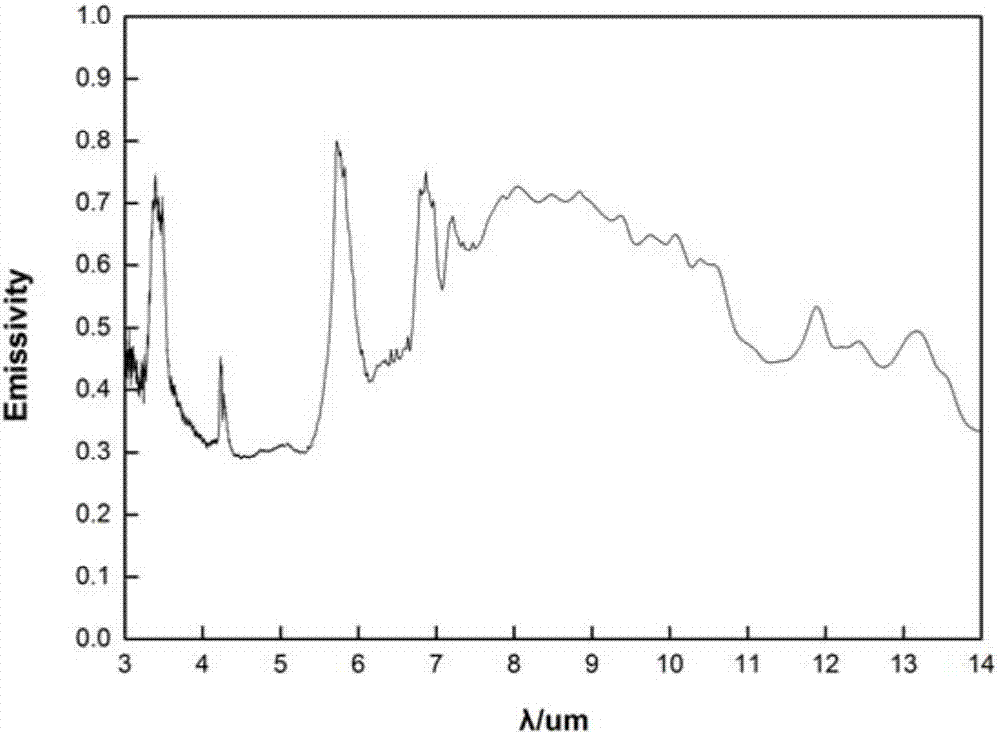

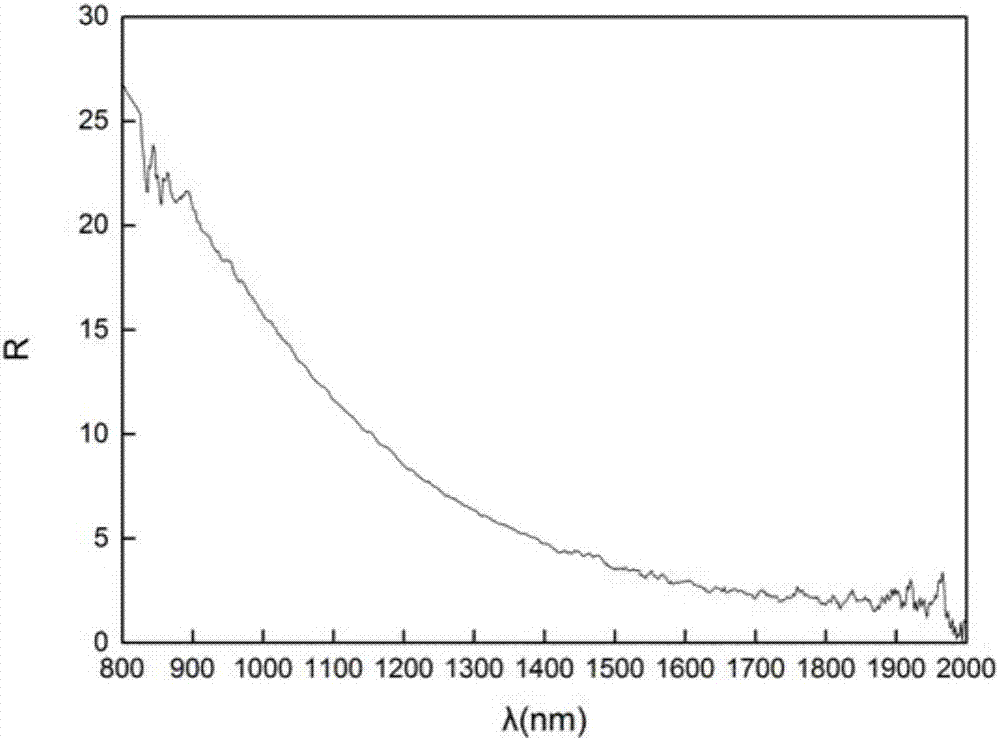

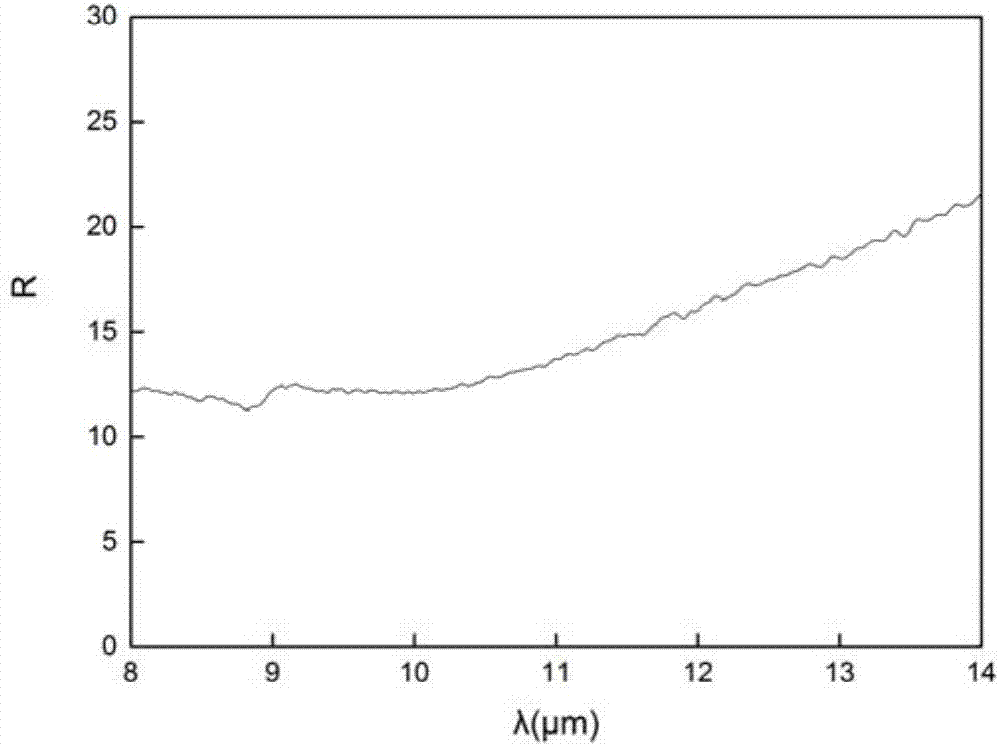

[0047] The coating thus prepared has an emissivity of 0.4 ( figure 1 ); In the infrared band 8 ~ 14um emissivity is 0.6 ( figure 1 ); the reflectance in the 1.06um laser band is 0.12 ( figure 2 ); the reflectance in the 10.6um laser band is 0.13 ( image 3 );

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com