A hybrid fiber reinforced thermoplastic resin composite sucker rod centralizer and its preparation method

A technology of resin composite materials and reinforced thermoplastics, which is applied in drill pipes, earthwork drilling, drilling equipment, etc., can solve the problems of metal shavings easy to get stuck in the pump, poor wear characteristics, hard metal materials, etc., to improve clamping stability, Effect of reducing wear and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

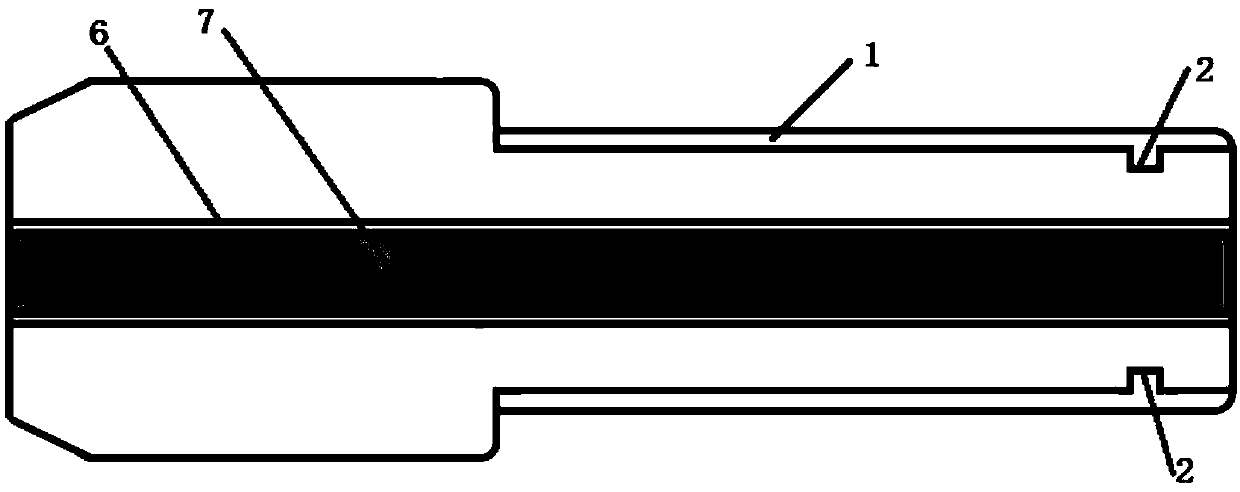

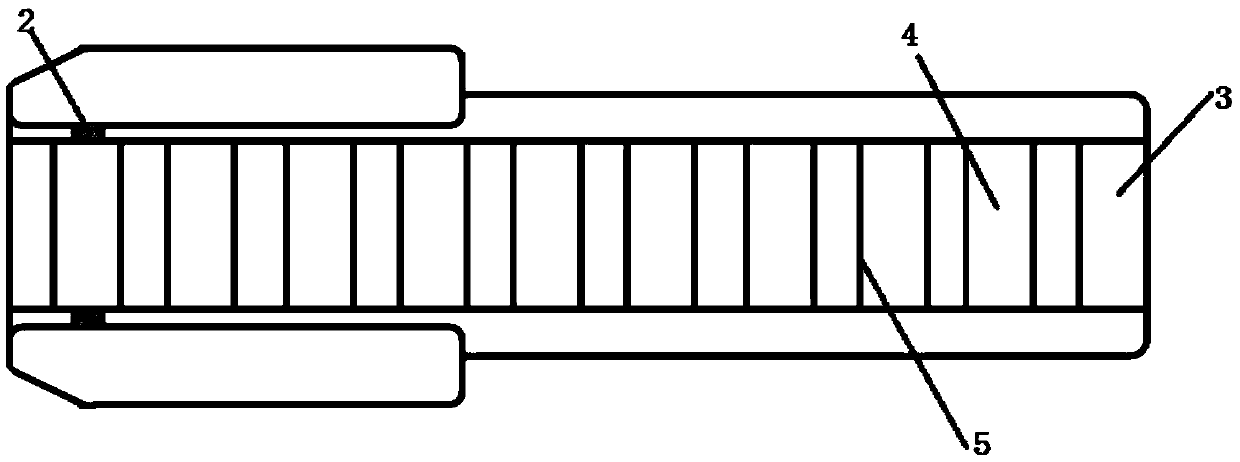

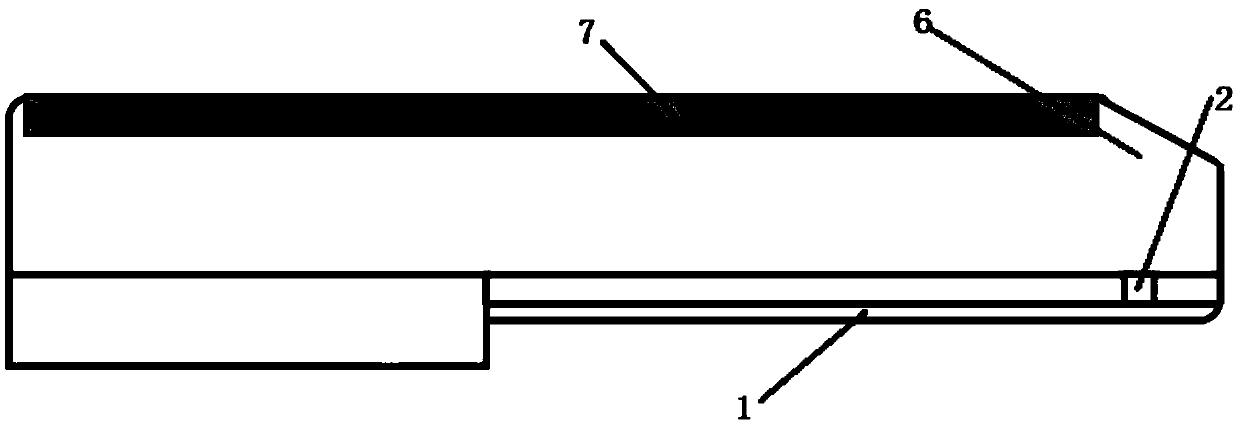

Embodiment 1

[0032] A mixture of T300 carbon fiber and S-type glass fiber is selected as the fiber reinforcement material, the fiber length is 1cm, the mixing ratio of T300 carbon fiber and S-type glass fiber is 1:3, and PP resin is used as the matrix to prepare a composite sucker rod centralizer. The whole centralizer is processed by injection molding, the injection molding temperature is 100°C, the molding pressure is 2MPa, and the content of fiber reinforced material is 5%;

[0033] The centralizer adopts a two-half symmetrical structure. There is a clamping groove with a thickness of 10mm, a width of 40mm and a length of 200mm inside the centralizer. The raised bar on the surface of the clamping groove increases the contact interface friction between the surface of the flat belt sucker rod and the surface of the holding groove. There is a rubber storage tank between the raised bars adjacent to the holding groove. When the centralizer is aligned , Adhesive glue can be stored in the glue...

Embodiment 2

[0036] A mixture of S-type glass fiber and basalt fiber is selected as the fiber reinforcement material, the fiber length is 2 cm, the mixing ratio of glass fiber and basalt fiber is 4:1, and nylon resin is used as the matrix to prepare a composite sucker rod centralizer. The whole centralizer is processed by injection molding, the injection molding temperature is 400°C, the molding pressure is 25MPa, and the content of fiber reinforced material is 20%;

[0037] The centralizer adopts a two-half symmetrical structure, and there is a clamping groove with a thickness of 3mm, a width of 10mm, and a length of 50mm on the inner side of the centralizer. The raised bar on the surface of the clamping groove increases the contact interface friction between the surface of the flat belt sucker rod and the surface of the holding groove. There is a rubber storage tank between the raised bars adjacent to the holding groove. When the centralizer is aligned , Adhesive glue can be stored in th...

Embodiment 3

[0040] The basalt fiber is selected as the fiber reinforced material, the fiber length is 1cm, and the thermoplastic PPS resin is used as the matrix to prepare the composite sucker rod centralizer. The whole centralizer is processed by injection molding, the injection molding temperature is 300°C, the molding pressure is 25MPa, and the content of fiber reinforced material is 12%;

[0041] The centralizer adopts a two-half symmetrical structure. There is a clamping groove with a thickness of 5mm, a width of 12mm, and a length of 52mm inside the centralizer. The raised bar on the surface of the clamping groove increases the contact interface friction between the surface of the flat belt sucker rod and the surface of the holding groove. There is a rubber storage tank between the raised bars adjacent to the holding groove. When the centralizer is aligned , Adhesive glue can be stored in the glue storage tank to prevent extrusion outflow. During the mating process, the single half...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com