Aluminum parting strip bending machine control system with remote wireless monitoring function

A control system and remote wireless technology, applied in the field of machinery, can solve the problems that the bending machine cannot realize remote monitoring, the database management program is difficult, the application software is not rich, etc., and achieves normal database access, accurate data storage, and good promotion prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

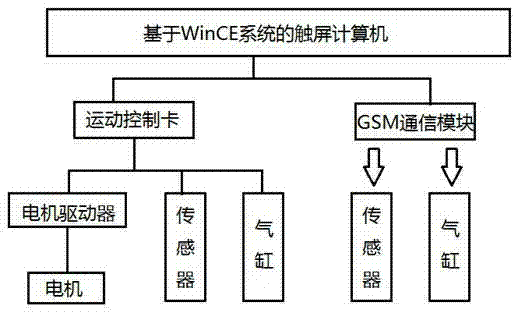

[0015] Such as figure 1 , the control system is mainly composed of industrial touch screen computer based on WinCE system, CSM wireless communication module, motion control card, sensors and other components. The upper computer based on WinCE sends processing instructions to the motion control card. After receiving the instructions, the motion control card controls the motor and cylinder to complete the corresponding actions, and receives the feedback signal to realize the processing of aluminum spacers. Through the wireless communication module, the remote wireless monitoring of the bending machine is completed by sending and receiving short messages using CSM technology.

[0016] The WLT_TFT800 x 600 type 10-inch industrial touch screen computer is selected as the upper computer of the control system. This computer uses the Windows CE6. 0 operating system with stable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com