Pre-charging method for lithium ion battery

A lithium-ion battery and pre-charging technology, which is applied in the direction of secondary battery charging/discharging, secondary batteries, battery electrodes, etc., can solve the problems of slow electrochemical reaction rate, poor performance of high-current charging and discharging, etc. The effect of charging time, excellent electrical performance, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the invention will be further described in detail below.

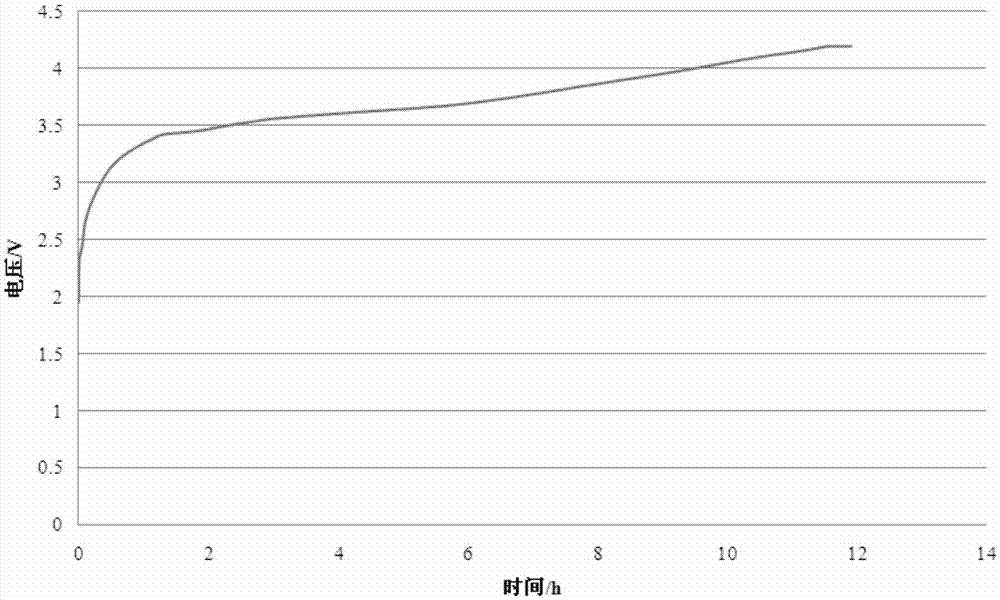

[0036] Such as figure 1 As shown, a lithium-ion battery precharging method of an embodiment, wherein, the positive electrode active material of the lithium-ion battery is a nickel-cobalt-aluminum material, the negative electrode of the lithium-ion battery is a graphite negative electrode, and the lithium-ion battery precharging method is sequentially Including a staged charging step and a constant voltage charging step, that is, the staged charging step is before the constant voltage charging step;

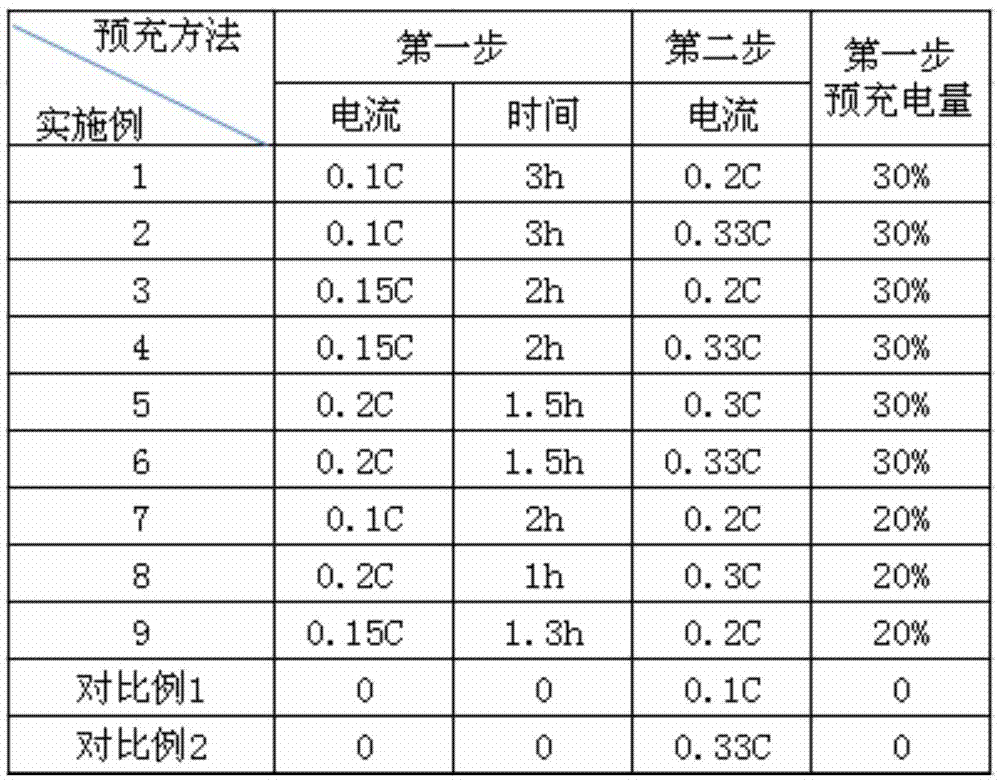

[0037] Wherein, the staged charging step includes a first charging step and a second charging step in sequence, the current of the first charging step is smaller than the current of the second charging step, and the pre-charging amount of the first charging step is the 20%-40% of the total charge of the lithium-ion battery.

[0038] The use of a small current in the first charging step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com