Structure and manufacturing method of third-order distributed feedback terahertz quantum cascade laser

A quantum cascade, terahertz technology, applied in lasers, phonon exciters, laser components, etc., can solve the problems of large far-field divergence angle, phase mismatch, far-field spot difference, etc., to overcome the far-field divergence The effect of large angle and large coupling power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

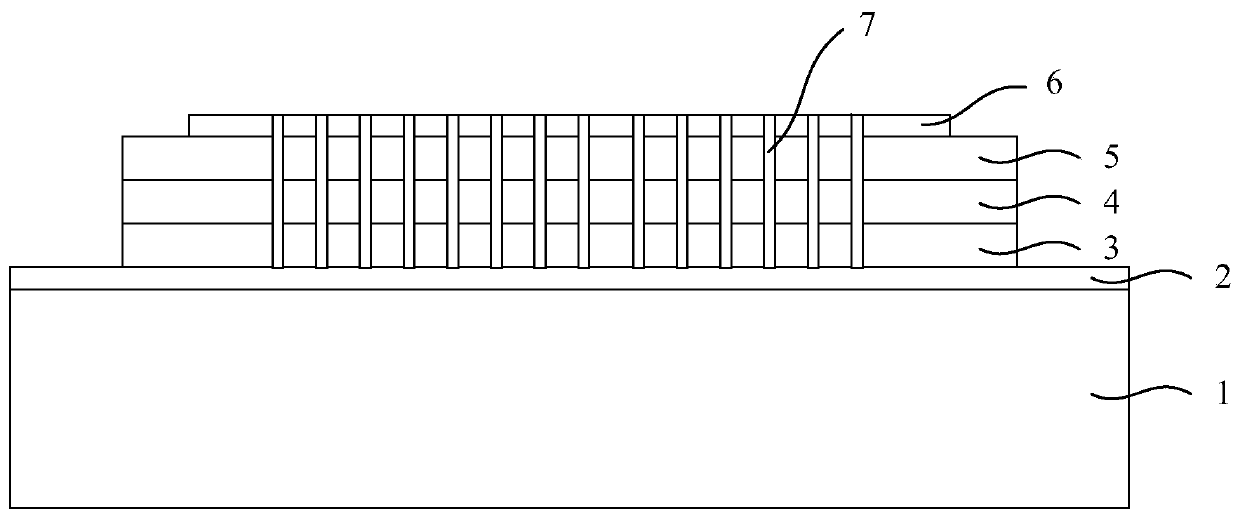

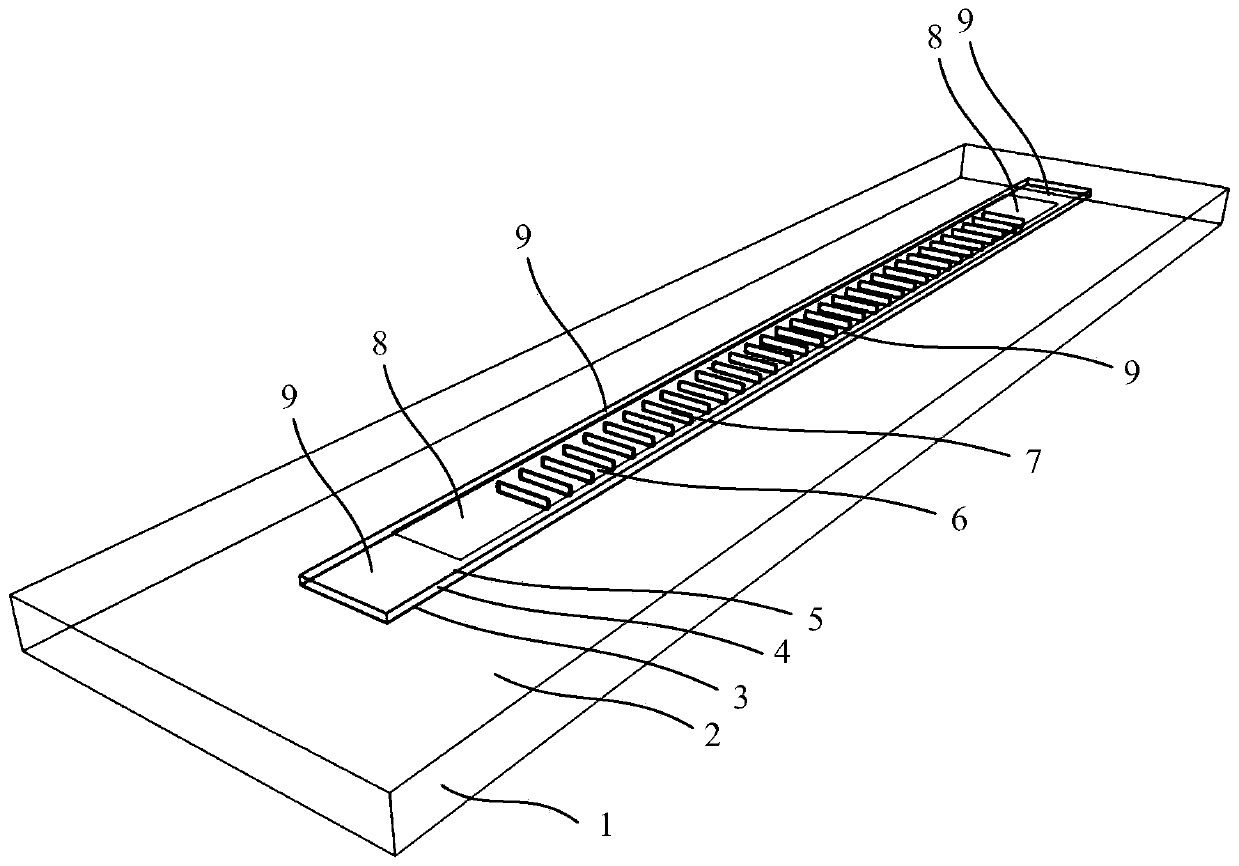

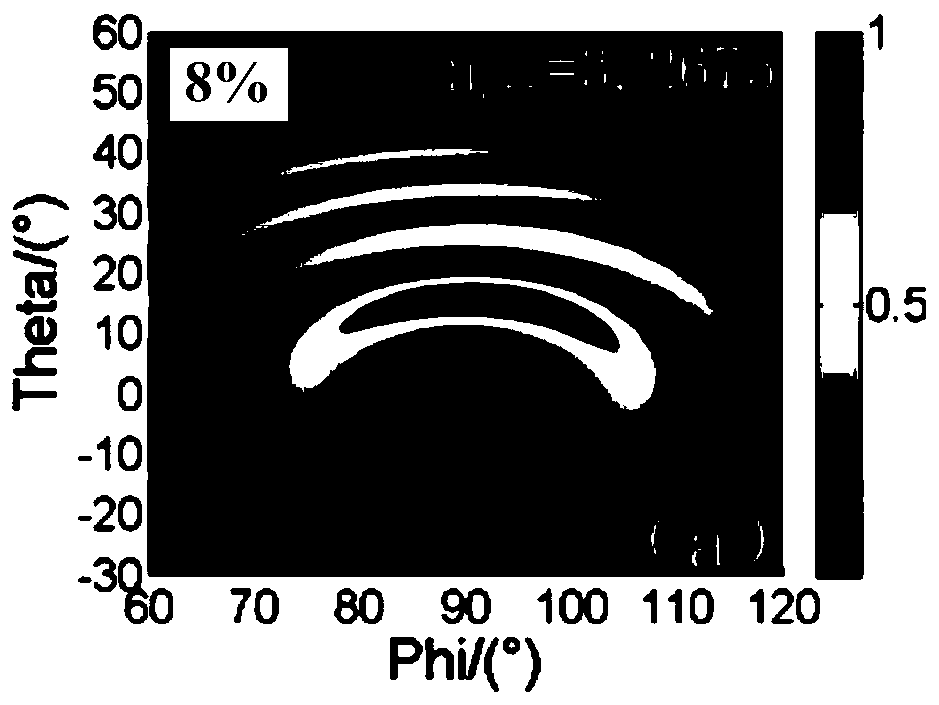

[0051] In order to solve the phase mismatch problem of the third-order distributed feedback terahertz quantum cascade laser, the present invention proposes a manufacturing scheme of a terahertz quantum cascade laser with high output power and small far-field divergence angle by changing the structure of the waveguide. see Figure 1a and Figure 1b , which are respectively shown as a cross-sectional schematic diagram and a three-dimensional schematic diagram of the third-order distributed feedback terahertz quantum cascade laser structure of the present invention, including a substrate 1, a ridge waveguide region formed on the substrate 1, and a ridge waveguide region formed on the ridge waveguide region The third-order grating structure in 7; where:

[0052] The ridge waveguide region sequentially includes a lower electrode 2, an interlayer region and an upper electrode 6 from bottom to top;

[0053] The interlayer region sequentially includes a lower contact layer 3, an acti...

Embodiment 2

[0070] The present invention also provides a method for manufacturing a third-order distributed feedback terahertz quantum cascade laser structure, including the following steps:

[0071] Step S1 is first performed: a substrate is provided, and an etch barrier layer, an upper contact layer, an active region, a lower contact layer, and a first bonding metal layer are sequentially formed on the substrate from bottom to top.

[0072] As an example, the step S1 includes:

[0073] S1-1: Using a semi-insulating GaAs wafer as a substrate, grow about 400 nm thick Al on the substrate by molecular beam epitaxy (MBE) 0.5 Ga 0.5 As etch stop layer;

[0074] S1-2: MBE grows a heavily doped n-type GaAs upper contact layer with a thickness of about 400 nanometers on the etching barrier layer, and its function is to make the metal and GaAs form a non-alloy ohmic contact;

[0075] S1-3: MBE growing an AlGaAs / GaAs alternating multilayer periodic structure active region on the contact layer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com