Flexible welding system capable of horizontally rotating and shifting car models

A technology of horizontal rotation and welding system, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding efficiency, difficult automatic robot welding, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

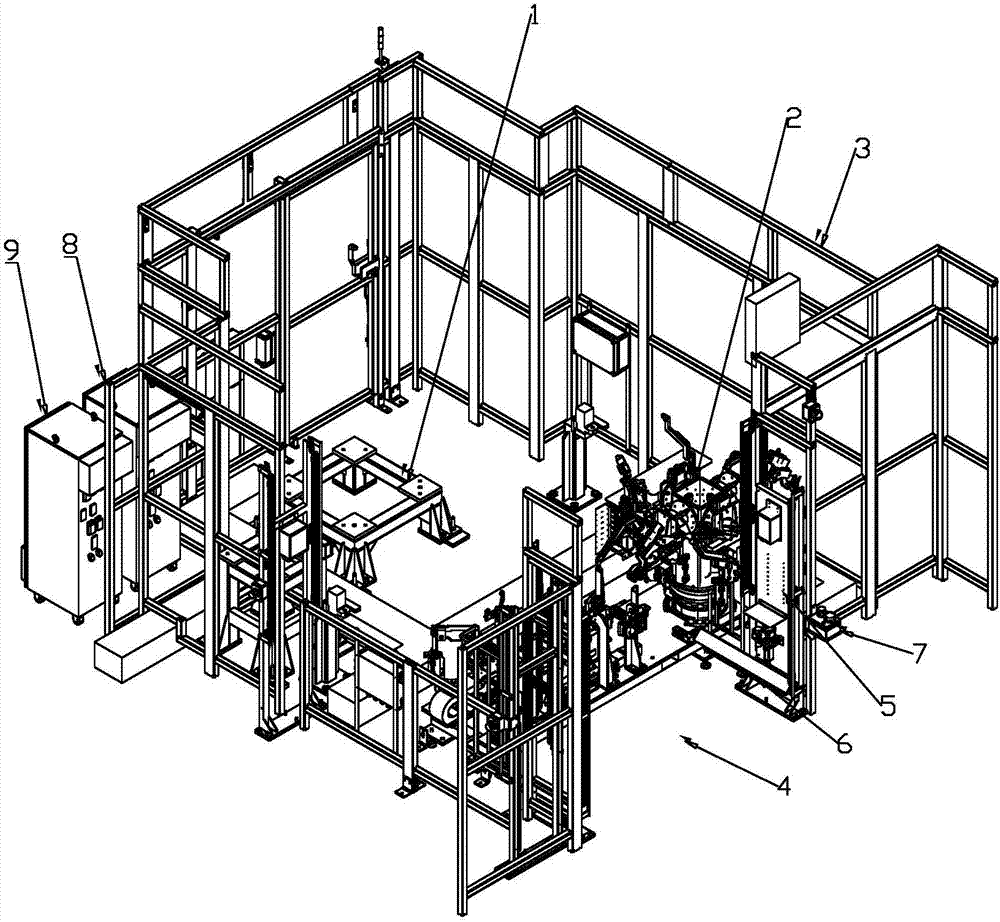

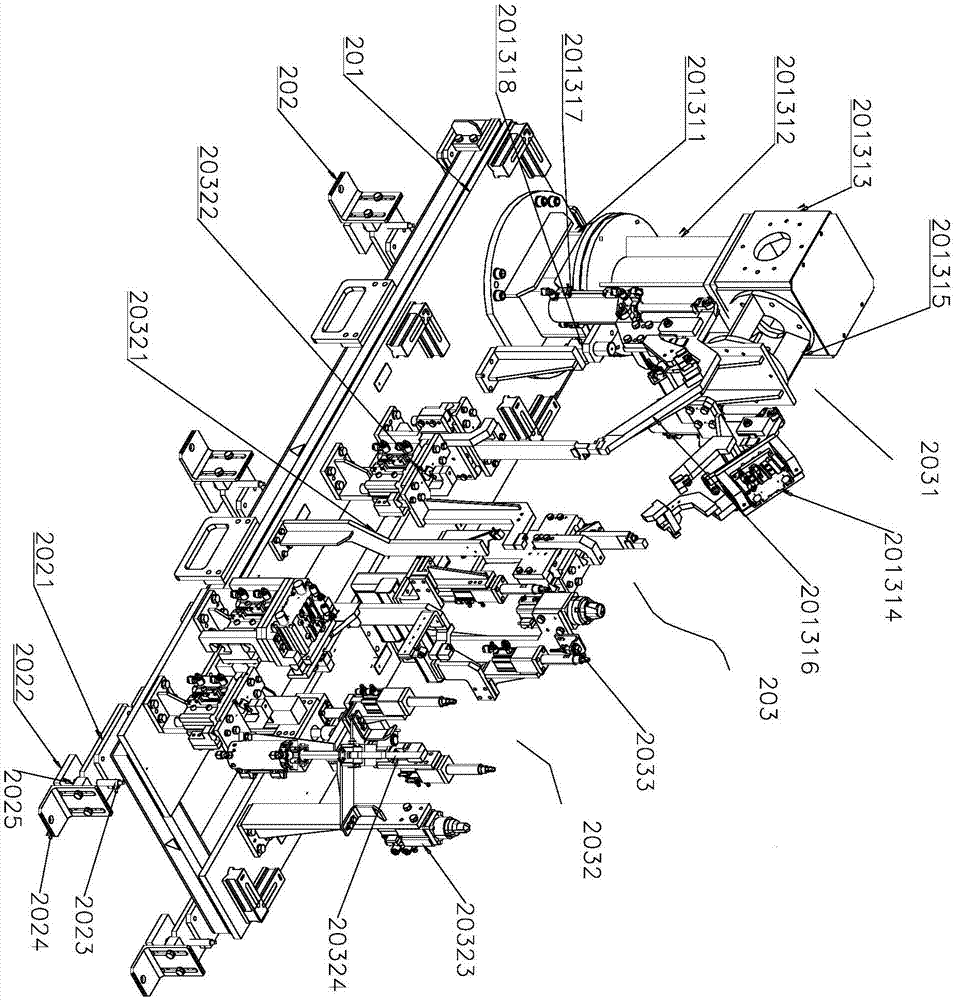

[0019] Such as figure 1 , 2 As shown, the horizontally rotating vehicle switching flexible welding system includes a welding robot (not shown in the figure). The welding robot is installed and fixed by the robot stand 1, and a welding table 2 for placing the workpiece is provided on one side of the welding robot. There is a safety fence 3 around the welding robot and welding workbench 2, the corresponding safety fence 3 on the other side of the welding workbench 2 is equipped with a manual pick-and-place part 4, and the manual pick-and-place part 4 is equipped with a manual guardrail (not shown in the figure) Out), safety grating 5, foot grating 6, operation panel 7. The outer side of the safety fence 3 is provided with a robot control cabinet 8 and a welding workbench control cabinet 9; the welding robot is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com