Comprehensive utilization method of waste acids of titanium dioxide industry

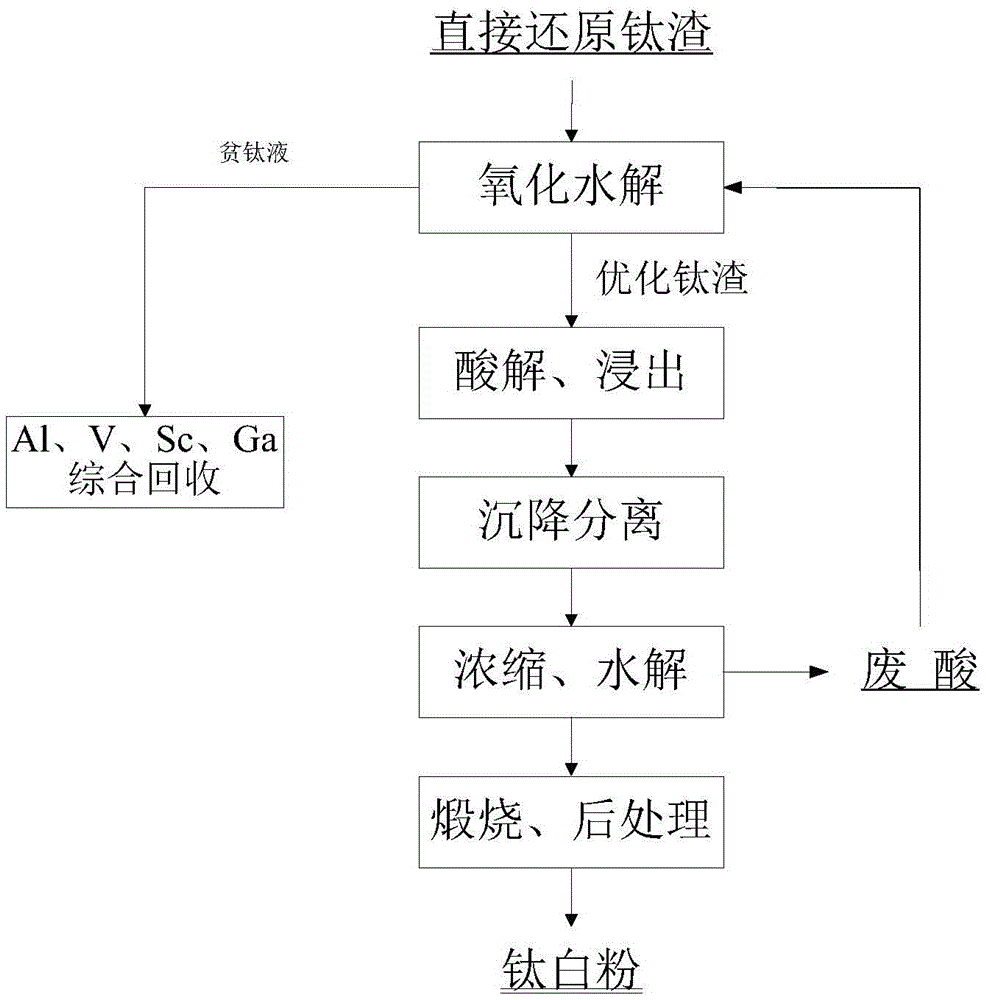

A technology for titanium dioxide waste acid and titanium dioxide, which is applied in the field of titanium dioxide waste acid treatment of vanadium titanomagnetite, direct reduction of titanium slag, comprehensive recovery of titanium, vanadium, comprehensive utilization of titanium dioxide waste acid, aluminum and scandium, and can solve the problem of titanium dioxide. Unable to recover, process or reuse high cost, difficulty in comprehensive utilization of vanadium-titanium magnetite directly reduced titanium slag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Titanium slag with a particle size of less than 74 μm and accounting for 90% was finely ground, and titanium dioxide waste acid with a mass concentration of sulfuric acid of 25% and titanium of 5 g / L was added at a solid-liquid mass ratio of 1:5, and the reaction was stirred at 90 ° C for 12 h. The leached pulp was filtered to obtain the optimized titanium slag with water content of 10% and a titanium-depleted liquid containing 0.2 g / L of titanium and 45 g / L of sulfuric acid. The aluminum dissolution rate in the titanium slag was 65%, and then the optimized titanium slag was added into the The acidolysis reaction is carried out in the acidolysis tank of concentrated sulfuric acid. The acid-to-ore ratio of the acidolysis process is 1.8, the concentration of sulfuric acid is 98%, and the acidolysis temperature is 180°C. After the acid hydrolysis reaction is completed, the slurry is cured, and the curing temperature is 200° C., and the curing holding time is 2h. After the ...

Embodiment 2

[0034] Titanium slag with a particle size of less than 74 μm and accounting for 90% was finely ground, and titanium dioxide waste acid with a mass concentration of sulfuric acid of 20% and titanium of 8 g / L was added at a solid-liquid mass ratio of 1:5, and the reaction was stirred at 100 ° C for 12 h. The leached pulp was filtered to obtain the optimized titanium slag with water content of 10% and the titanium-depleted liquid containing 0.2g / L of titanium and 25g / L of sulfuric acid. The aluminum dissolution rate in the titanium slag was 75%, and then the optimized titanium slag was added into the The acidolysis reaction is carried out in the acidolysis tank of concentrated sulfuric acid. The acid-to-ore ratio of the acidolysis process is 1.6, the concentration of sulfuric acid is 98%, and the acidolysis temperature is 180°C. After the acid hydrolysis reaction is completed, the slurry is cured, and the curing temperature is 200° C., and the curing holding time is 2h. After the...

Embodiment 3

[0037] Titanium slag with a particle size of less than 74 μm and accounting for 90% was finely ground, and titanium dioxide waste acid with a mass concentration of sulfuric acid of 20% and titanium of 8g / L was added at a solid-liquid mass ratio of 1:3, and the reaction was stirred at 150 ° C for 4 hours. The leached pulp was filtered to obtain the optimized titanium slag with water content of 10% and a titanium-depleted liquid containing 0.2 g / L of titanium and 15 g / L of sulfuric acid. The aluminum dissolution rate in the titanium slag was 85%, and then the optimized titanium slag was added into the The acidolysis reaction is carried out in the acidolysis tank of concentrated sulfuric acid. The acid-to-ore ratio of the acidolysis process is 1.6, the concentration of sulfuric acid is 98%, and the acidolysis temperature is 180°C. After the acid hydrolysis reaction is completed, the slurry is cured, and the curing temperature is 200° C., and the curing holding time is 2h. After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com