Method for Improving the Dewatering Performance of Surplus Sludge in Urban Sewage Treatment Plant

A technology for excess sludge and municipal sewage, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

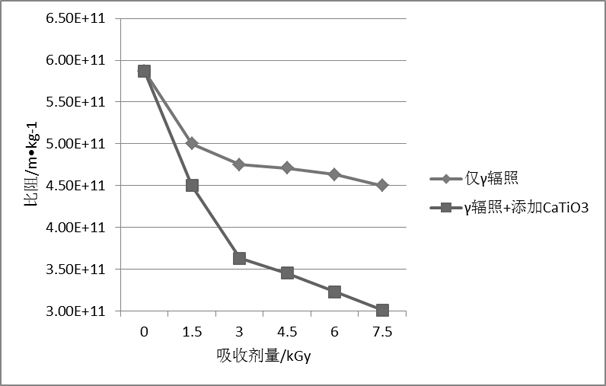

Embodiment 1

[0016] (1) Take 1000mL of remaining sludge sample, its moisture content is 85%, and its sludge specific resistance is 5.864×10 11 m / kg, pH 6.7, with 1mol / L H 2 SO 4 Solution and 10g / L NaOH solution to adjust its pH to 7.0, 1000mL sludge sample was divided into 10 sealed sample bottles with a capacity of 100mL, and each volumetric bottle was filled with 100mL sludge sample. Divide 10 volumetric flasks containing sludge samples into Group 1 and Group 2, 5 in each group, and the 5 volumetric flasks in Group 1 are labeled 1-1, 1-2, 1-3, 1- No. 4 and No. 1-5, in which the 5 volumetric flasks in the second group are respectively marked No. 2-1, 2-2, 2-3, 2-4 and 2-5.

[0017] (2) Add 0.02g of CaTiO with a diameter of 10nm to the sample vials 1-1, 1-2, 1-3, 1-4 and 1-5 of the first group 3 powder and shake it by hand.

[0018] (3) Place the first group of samples and the second group of samples in the central channel of gamma irradiation for irradiation treatment. The irradiation...

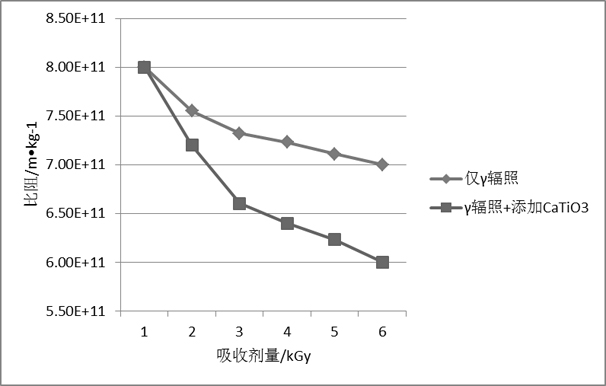

Embodiment 2

[0022] (1) Take 1000mL of remaining sludge sample, its moisture content is 85%, and its sludge specific resistance is 5.864×10 11 m / kg, pH 6.7, with 1mol / L H 2 SO 4 Solution and 10g / L NaOH solution to adjust its pH to 10.0, divide 1000mL sludge sample into 10 sealed sample bottles with a capacity of 100mL, and each volumetric bottle contains 100mL sludge sample. Divide 10 volumetric flasks containing sludge samples into Group 1 and Group 2, 5 in each group, and the 5 volumetric flasks in Group 1 are labeled 1-1, 1-2, 1-3, 1- No. 4 and No. 1-5, in which the 5 volumetric flasks in the second group are respectively marked No. 2-1, 2-2, 2-3, 2-4 and 2-5.

[0023] (2) Add 0.02g of CaTiO with a diameter of 10nm to the sample vials 1-1, 1-2, 1-3, 1-4 and 1-5 of the first group 3 powder and shake it by hand.

[0024] (3) Place the first group of samples and the second group of samples in the central channel of gamma irradiation for irradiation treatment. The irradiation time of vo...

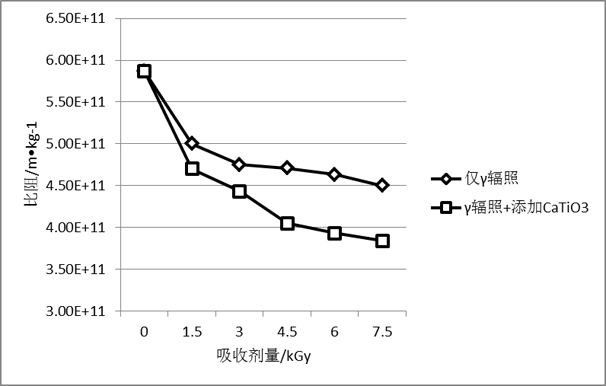

Embodiment 3

[0028] (1) Take 1000mL of remaining sludge sample, its moisture content is 85%, and its sludge specific resistance is 5.864×10 11 m / kg, pH 6.7, with 1mol / L H 2 SO 4 Solution and 10g / L NaOH solution to adjust its pH to 7.0, 1000mL sludge sample was divided into 10 sealed sample bottles with a capacity of 100mL, and each volumetric bottle was filled with 100mL sludge sample. Divide 10 volumetric flasks containing sludge samples into Group 1 and Group 2, 5 in each group, and the 5 volumetric flasks in Group 1 are labeled 1-1, 1-2, 1-3, 1- No. 4 and No. 1-5, in which the 5 volumetric flasks in the second group are respectively marked No. 2-1, 2-2, 2-3, 2-4 and 2-5.

[0029] (2) Add 0.02g of CaTiO with a diameter of 100nm to the sample vials 1-1, 1-2, 1-3, 1-4 and 1-5 of the first group 3 powder and shake it by hand.

[0030] (3) Place the first group of samples and the second group of samples in the central channel of gamma irradiation for irradiation treatment. The irradiatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com