Novel technology for producing hexamethyl disilazane from trimethyl chlorosilane

A technology of hexamethyldisilazane and trimethylchlorosilane, which is applied in the new process field of producing hexamethyldisilazane from trimethylchlorosilane, can solve the problems such as the reduction of the yield of the target product, and achieve The effect of product reduction, simple process and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

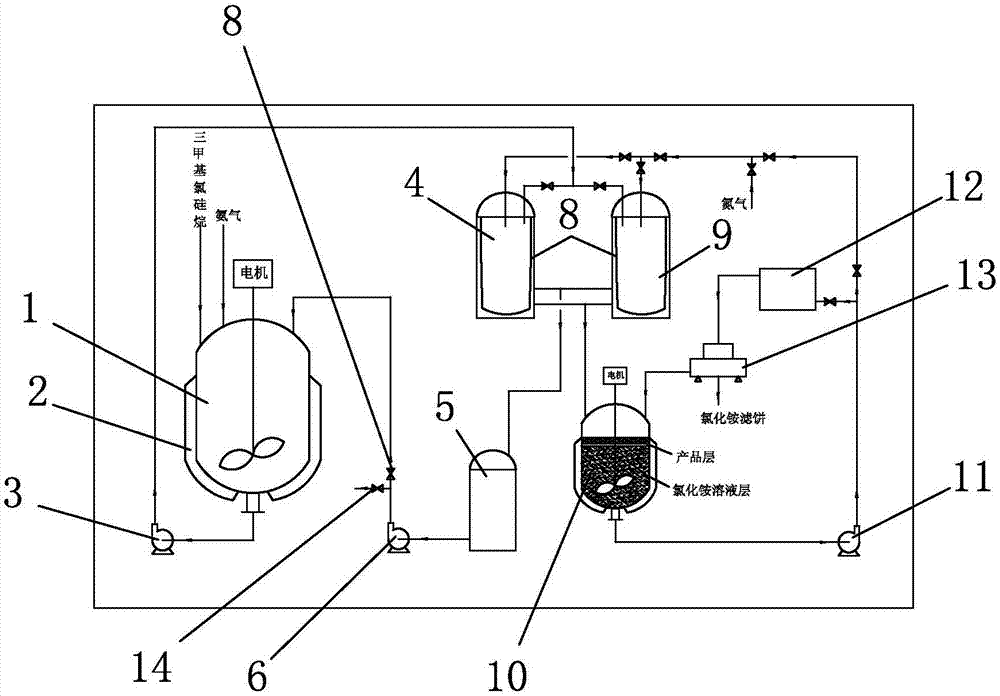

Method used

Image

Examples

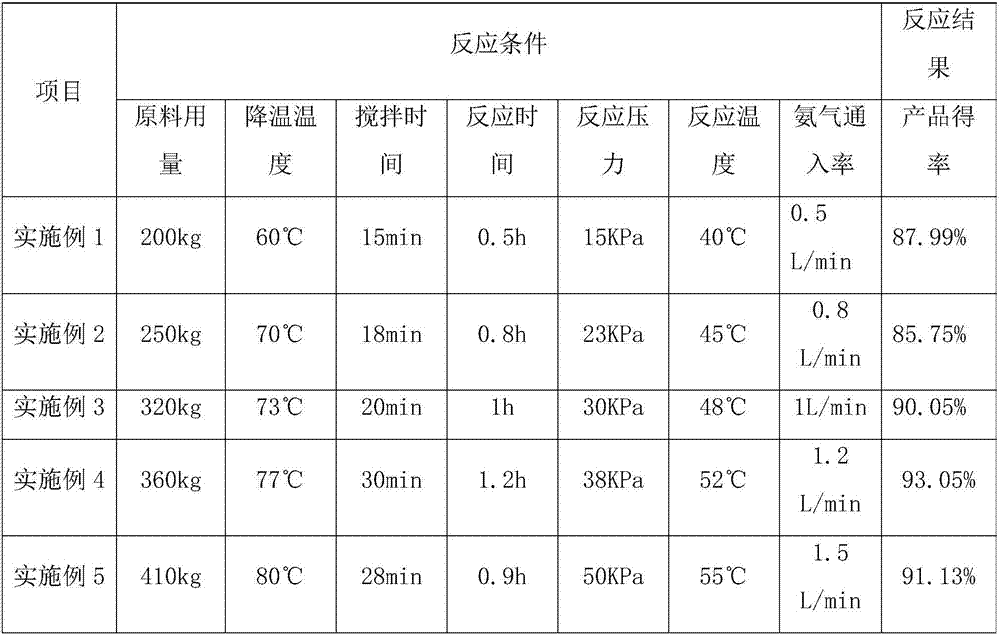

Embodiment 1

[0035] Add 200kg trimethylchlorosilane into the reaction kettle, stir, and the stirring time is 15min. After the stirring is completed, add ice brine to the jacket outside the reaction kettle for cooling and cooling until the temperature in the reaction kettle drops to 60°C. The slurry discharge pump makes the trimethylchlorosilane flow into the mother liquor buffer tank through the first filter, and then returns to the reactor. At the same time, feed ammonia gas into the reactor, the feed rate of ammonia gas is 0.5L / min, the molar mass ratio of ammonia gas to trimethylchlorosilane is 3.0:2, the reaction temperature is 40°C, and the reaction time is 0.5h , the trimethylchlorosilane in the reactor reacts with ammonia to generate a mixed slurry of liquid hexamethyldisilazane and solid ammonium chloride, and the mixed slurry flows into the mother liquor buffer tank through the first filter, so that the solid Ammonium chloride is deposited on the screen of the first filter.

[00...

Embodiment 2

[0040] Add 250kg of trimethylchlorosilane into the reaction kettle and stir for 18 minutes. After the stirring is completed, add ice salt water to the jacket outside the reaction kettle for cooling and cooling until the temperature in the reaction kettle drops to 70°C. The slurry discharge pump makes the trimethylchlorosilane flow into the mother liquor buffer tank through the first filter, and then returns to the reactor. At the same time, feed ammonia gas into the reactor, the feed rate of ammonia gas is 0.8L / min, the molar mass ratio of ammonia gas to trimethylchlorosilane is 3.1:2, the reaction temperature is 45°C, and the reaction time is 0.8h , the trimethylchlorosilane in the reactor reacts with ammonia to generate a mixed slurry of liquid hexamethyldisilazane and solid ammonium chloride, and the mixed slurry flows into the mother liquor buffer tank through the first filter, so that the solid Ammonium chloride is deposited on the screen of the first filter.

[0041] Wh...

Embodiment 3

[0045] Add 320kg trimethylchlorosilane into the reaction kettle, stir, and the stirring time is 20min. After the stirring is completed, add ice salt water to the jacket outside the reaction kettle for cooling and cooling until the temperature in the reaction kettle drops to 73°C. The slurry discharge pump makes the trimethylchlorosilane flow into the mother liquor buffer tank through the first filter, and then returns to the reactor. At the same time, feed ammonia gas into the reaction kettle, the feed rate of ammonia gas is 1L / min, the molar mass ratio of ammonia gas to trimethylchlorosilane is 3.3:2, the reaction temperature is 48°C, and the reaction time is 1h, so that The trimethylchlorosilane in the reaction kettle reacts with ammonia gas to generate a mixed slurry of liquid hexamethyldisilazane and solid ammonium chloride, and the mixed slurry flows into the mother liquor buffer tank through the first filter to make the solid chlorination Ammonium is deposited on the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com