Preparation method of fluoride-modified polyvinyl alcohol thin film

A technology of polyvinyl alcohol film and polyvinyl alcohol, which is applied in the direction of biocide-containing paints, coatings, antifouling/underwater coatings, etc., which can solve the problems of difficulty in preventing water vapor penetration, decreased barrier properties, and decreased tensile strength of films, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10 and comparative example 1~2

[0065] The preparation steps of fluoride-modified polyvinyl alcohol film are as follows:

[0066] 1) dissolving polyvinyl alcohol (purchased from Shanghai Kaidu Industrial Development Co., Ltd.) into a 7% aqueous solution, and then casting it into a film to prepare a film substrate;

[0067] 2) According to the formulation in Table 1, the surface treatment composition (the ratio of mass and number in the table) comprising fluoride is formulated, wherein Examples 1 to 7 and Comparative Example 1 also contain propionic acid, which accounts for 0.5wt% of hydrolyzable compound, Examples 8-10 and Comparative Example 2 also contain sorbic acid accounting for 0.5wt% of the hydrolyzable compound, and then dissolve the composition in a mixed solvent with a mass ratio of perfluorocyclic ether and butyl acetate of 1:1, and prepare a concentration of 1% solution;

[0068] 3) using a high-pressure spray gun to spray the surface treatment composition solution containing fluoride prepared i...

Embodiment 11~20 and comparative example 3~4

[0073] The preparation steps of fluoride-modified polyvinyl alcohol film are as follows:

[0074] 1) dissolving polyvinyl alcohol (purchased from Shanghai Kaidu Industrial Development Co., Ltd.) into a 7% aqueous solution, and then casting it into a film to prepare a film substrate;

[0075] 2) According to the formula in Table 2, prepare the non-fluorosiloxane compound composition (mass ratio in the table), and then dissolve the composition in butyl acetate and N,N-dimethylformamide with a mass ratio of 1: 1 mixed solvent, prepared into a solution with a concentration of 2%;

[0076] 3) using a high-pressure spray gun to spray the primer solution of the non-fluorosilicone compound composition prepared in 2) on one of the surfaces of the film substrate containing polyvinyl alcohol prepared in 1);

[0077] 4) prepare the surface treatment composition (mass ratio in the table) that comprises fluoride according to the formula in table 2, wherein embodiment 11~17 and comparative ...

Embodiment 4

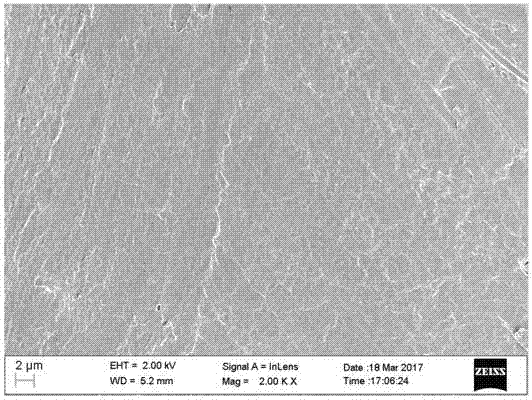

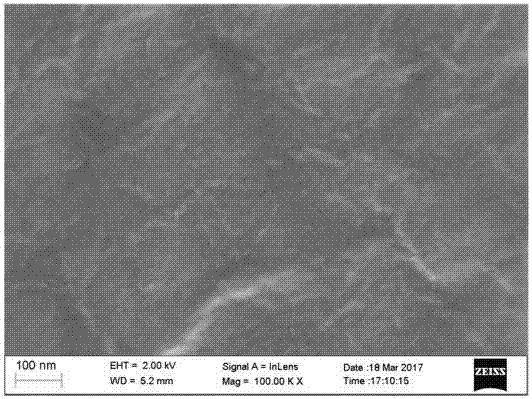

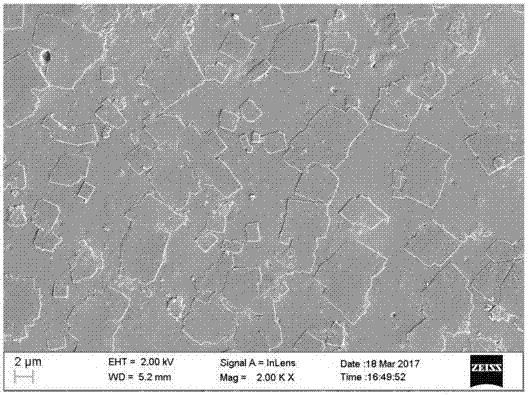

[0103] The environmental scanning electron microscope of embodiment 4 fluoride modified polyvinyl alcohol film is as figure 1 , 2 shown, from figure 1 It can be seen that the fluoride-modified polyvinyl alcohol film is smooth as a whole, without obvious large particle protrusions; from figure 2 It can be seen that the pattern on the surface of the fluoride-modified polyvinyl alcohol film is relatively smooth without obvious unevenness. Environmental scanning electron microscope of unmodified polyvinyl alcohol film (comparative example 7) such as image 3 , Figure 4 shown, from image 3 It can be seen that the overall surface of the unmodified film is rough with obvious protrusions; from Figure 4 It can be seen that there is a clear fracture surface at the raised edge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com