Coating system and application thereof

A coating and coating technology, which is applied in the direction of polyester coating, polyurea/polyurethane coating, coating, etc., can solve the problems of surface coating stress cracking, coating surface performance test is not up to standard, etc., to achieve smooth knife edge, excellent Adhesion performance, effect of reducing technical risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

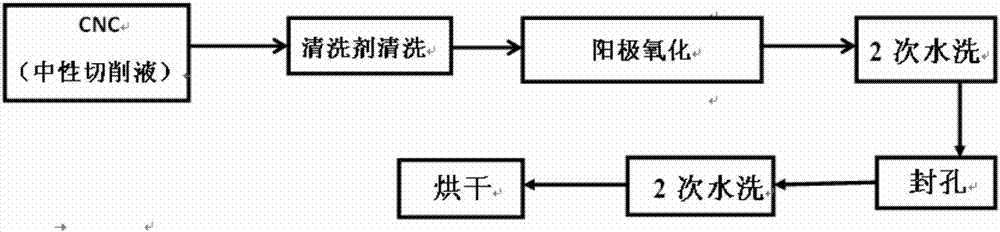

Method used

Image

Examples

Embodiment 1

[0041]The coating system that present embodiment provides, comprises primer, filler paint, color paint and finish paint, and primer comprises the polyester resin of 25 parts by weight, the pigment filler of 15 parts (comprising 10 parts of titanium dioxide, talcum powder 5 parts), 3 parts of adhesion promoter (organic phosphate compound in this embodiment), 0.5 parts of acrylic modified rheology modifier, 56.3 parts of diluent (including 20 parts of ethyl acetate, butyl acetate 26.3 parts, 10 parts of cyclohexanone), 0.2 parts of drier. Refer to Table 1 for the parts by weight of the above components.

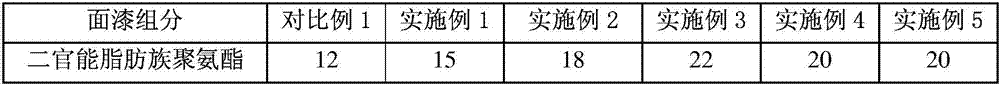

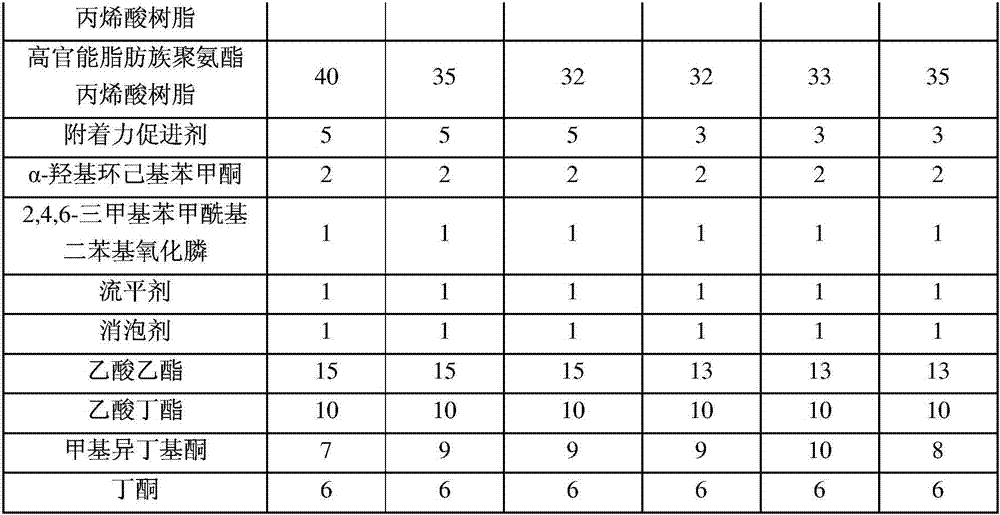

[0042] Table 1: Parts by weight of each component in the primer of Examples 1 to 5 and Comparative Example 1

[0043] Primer components Comparative example 1 Example 1 Example 2 Example 3 Example 4 Example 5 polyester resin - 25 30 30 30 30 Hydroxy Acrylic Resin 30 - - - - - Titanium dioxide 10 10 10 10 10 10 talcum p...

Embodiment 2

[0079] In the paint system of this embodiment, the parts by weight of each component in the primer, filler paint, color paint and top coat are respectively shown in Table 1 to Table 4, and the preparation method of each paint in the paint system is the same as in Example 1 .

Embodiment 3

[0081] In the paint system of this embodiment, the parts by weight of each component in the primer, filler paint, color paint and top coat are respectively shown in Table 1 to Table 4, and the preparation method of each paint in the paint system is the same as in Example 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com