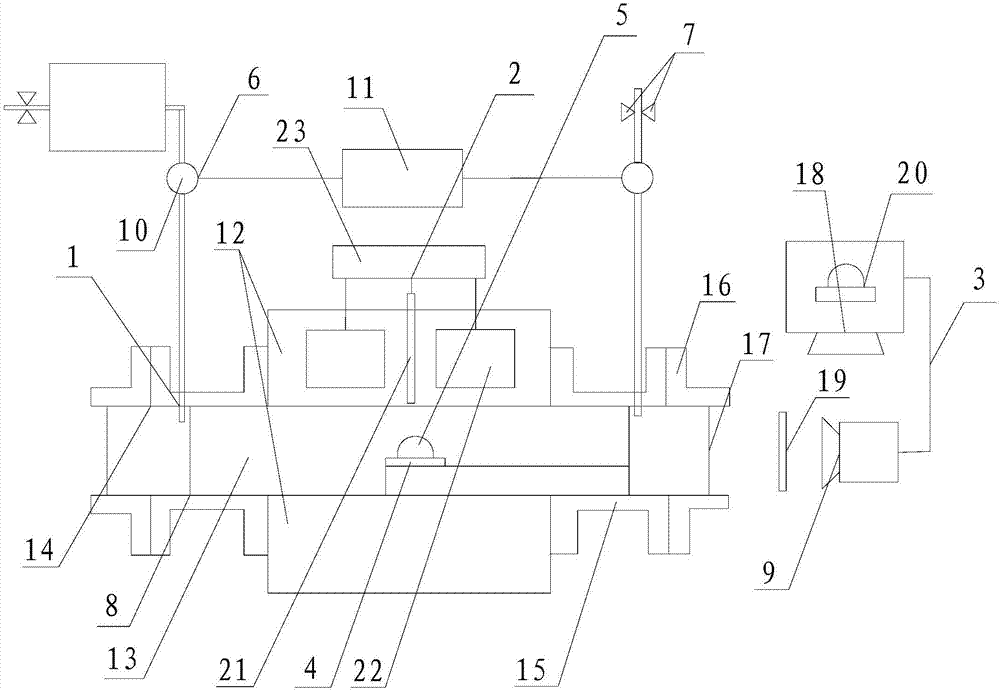

Determination device and determination method for metal solid/liquid phase interface energy

A measuring device and interfacial energy technology, which is applied to the measuring device of the metal solid/liquid phase interface energy, the determination of the metal solid/liquid phase interface energy, and the field of measuring devices, which can solve the problem that the oxygen content of the atmosphere cannot be accurately controlled online. and other problems to achieve the effect of avoiding oxidation and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

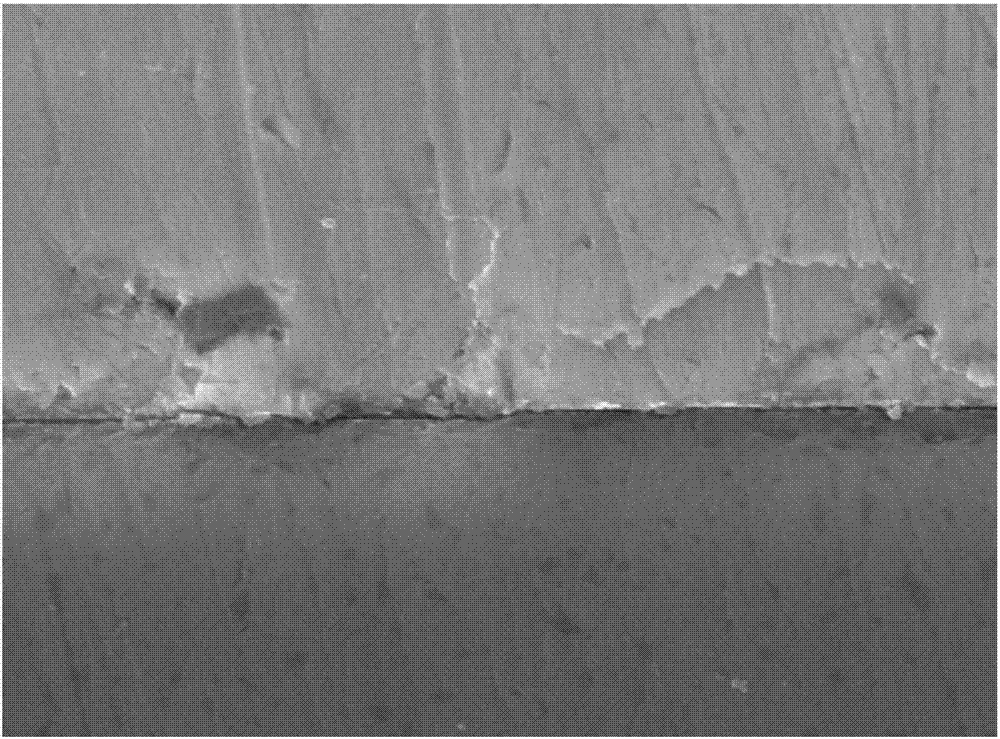

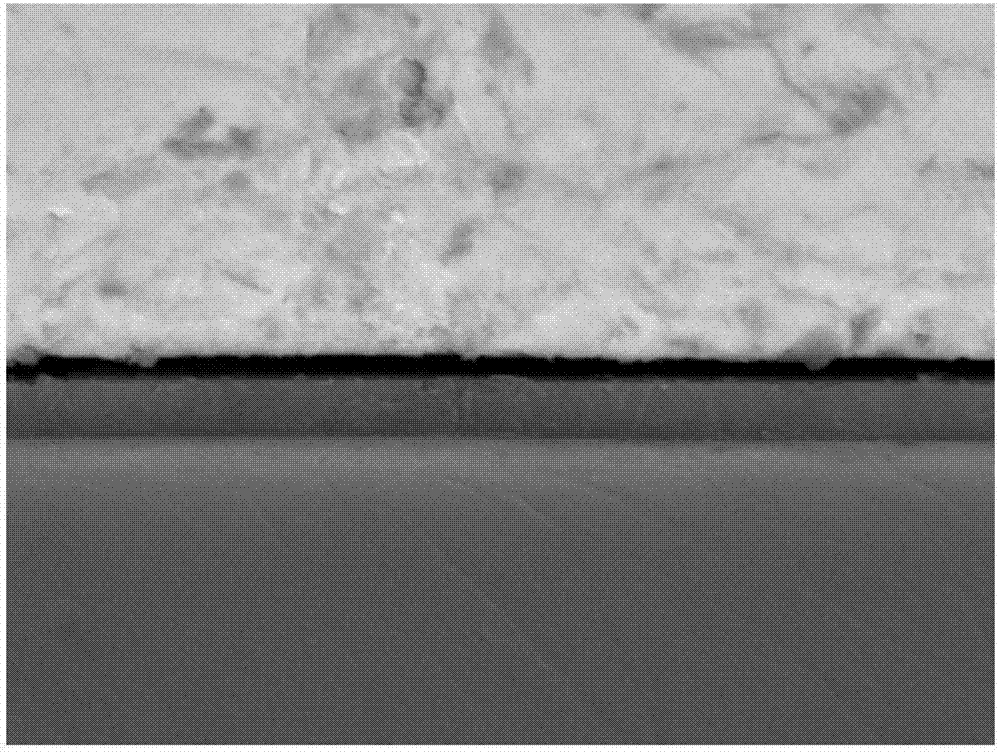

[0041] Determination of the interfacial energy between pure iron and a single crystal alumina substrate

[0042] 1. Open the fastening bolts between the observation window and the cooling water jacket, place the 0.2g pure iron sample on the single crystal alumina substrate and place them on the upper surface of the T-stage, and use the glass level to rotate the T-stage to place the substrate Adjust to a horizontal state;

[0043] 2. Close the observation window, close the gas inlet valve, open the gas outlet valve, and vacuumize with an external vacuum pump to make the vacuum degree in the furnace reach 8×10 at room temperature. -2 Pa and stable;

[0044] 3. Adjust the position of the digital high-speed camera so that the lens and the center of the metal sample are on the same horizontal line, and adjust the focal length of the high-speed camera;

[0045] 4. Turn off the external vacuum pump, close the outlet valve, open the deoxygenation purification system, open the intake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com