High-water-retention mine filling material

A mine filling and cement technology, applied in the field of coal mining, can solve the problems of lower final strength, short initial setting time, easy pipe plugging, etc., and achieve the effect of waste utilization, long initial setting time and high final setting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

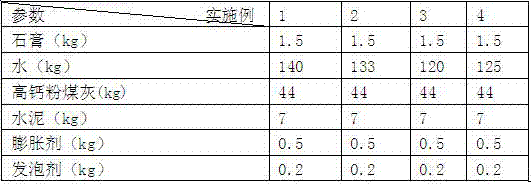

[0015] Example 1-4 Filling materials for mines with high water retention

[0016] This embodiment is respectively a high water retention mine filling material, and the specific ingredients are shown in the following table.

[0017]

[0018] The preparation methods of Examples 1-5 are as follows:

[0019] In the mixing equipment, first add water, then add high-calcium fly ash, continue to stir evenly, add the remaining materials at the same time, and stir for 15 minutes to get it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com