Formula and preparation method of nanometer heavy anti-corrosion coating

A heavy-duty anti-corrosion and coating technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve the problems of anti-corrosion effect and lifespan that cannot meet the needs, and achieve excellent anti-corrosion performance and high permeability resistance , long anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The formula of the nanometer heavy-duty anticorrosion coating that the present embodiment enumerates is made from the raw material of following weight: a kind of formula of nanometer heavy-duty anticorrosion coating, it is characterized in that: adopt following formula: 50 parts of epoxy resins, 5 parts of toughening resins, wax 2 parts of powder, 1 part of fumed silica, 1 part of leveling agent, 5 parts of n-butyl glycidyl ether, 10 parts of nano pulp, 1 part of carbon black, 0.5 parts of dispersant, 5 parts of benzyl alcohol, antifouling additive 1 part, 3 parts of alicyclic amine.

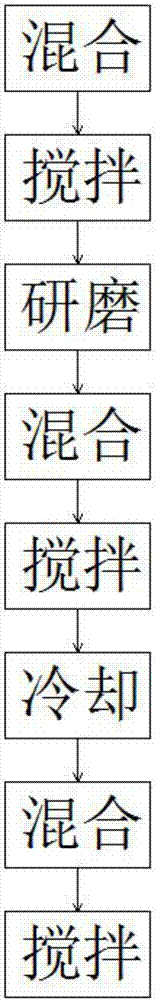

[0035] The preparation method of the nano heavy-duty anti-corrosion coating is carried out according to the following steps: wax powder, fumed silica, leveling agent, n-butyl glycidyl ether, dispersant, nano pulp, antifouling additive, carbon black and epoxy resin Mixing; Stir the mixture with a stirring disperser to make it evenly dispersed; then grind it into 20μm~30μm particles with a ...

Embodiment 2

[0041] The formula of the nanometer heavy-duty anticorrosion coating that present embodiment enumerates is made by the raw material of following weight: A kind of formula of nanometer heavy-duty anticorrosion coating, it is characterized in that: adopt following formula: 60 parts of epoxy resins, 15 parts of toughening resins, wax 3 parts of powder, 3 parts of fumed silica, 3 parts of leveling agent, 12 parts of n-butyl glycidyl ether, 20 parts of nano pulp, 2 parts of carbon black, 2 parts of dispersant, 8 parts of benzyl alcohol, antifouling additive 2 parts, 5 parts of alicyclic amine.

[0042] The preparation method of the nano heavy-duty anti-corrosion coating is carried out according to the following steps: wax powder, fumed silica, leveling agent, n-butyl glycidyl ether, dispersant, nano pulp, antifouling additive, carbon black and epoxy resin Mixing; Stir the mixture with a stirring disperser to make it evenly dispersed; then grind it into 20μm~30μm particles with a ho...

Embodiment 3

[0048]The formula of the nano heavy-duty anti-corrosion coating that present embodiment enumerates is made from the raw material of following weight: a kind of formula of nano-heavy anti-corrosion coating, it is characterized in that: adopt following formula: 55 parts of epoxy resins, 10 parts of toughening resins, wax 2.5 parts of powder, 2 parts of fumed silica, 2 parts of leveling agent, 8.5 parts of n-butyl glycidyl ether, 15 parts of nano pulp, 1.5 parts of carbon black, 1.25 parts of dispersant, 6.5 parts of benzyl alcohol, antifouling additive 1.5 parts, 4 parts of alicyclic amine.

[0049] The preparation method of the nano heavy-duty anti-corrosion coating is carried out according to the following steps: wax powder, fumed silica, leveling agent, n-butyl glycidyl ether, dispersant, nano pulp, antifouling additive, carbon black and epoxy resin Mixing; Stir the mixture with a stirring disperser to make it evenly dispersed; then grind it into 20μm~30μm particles with a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com