Rapid asphalt heating and extracting device for indoor experiment

A technology for rapid heating and extraction of equipment, which is applied in the direction of sampling, test sample preparation, and measuring devices, etc. It can solve problems such as heat loss, low heating efficiency, and delay in test progress, and achieve the effect of preventing segregation and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

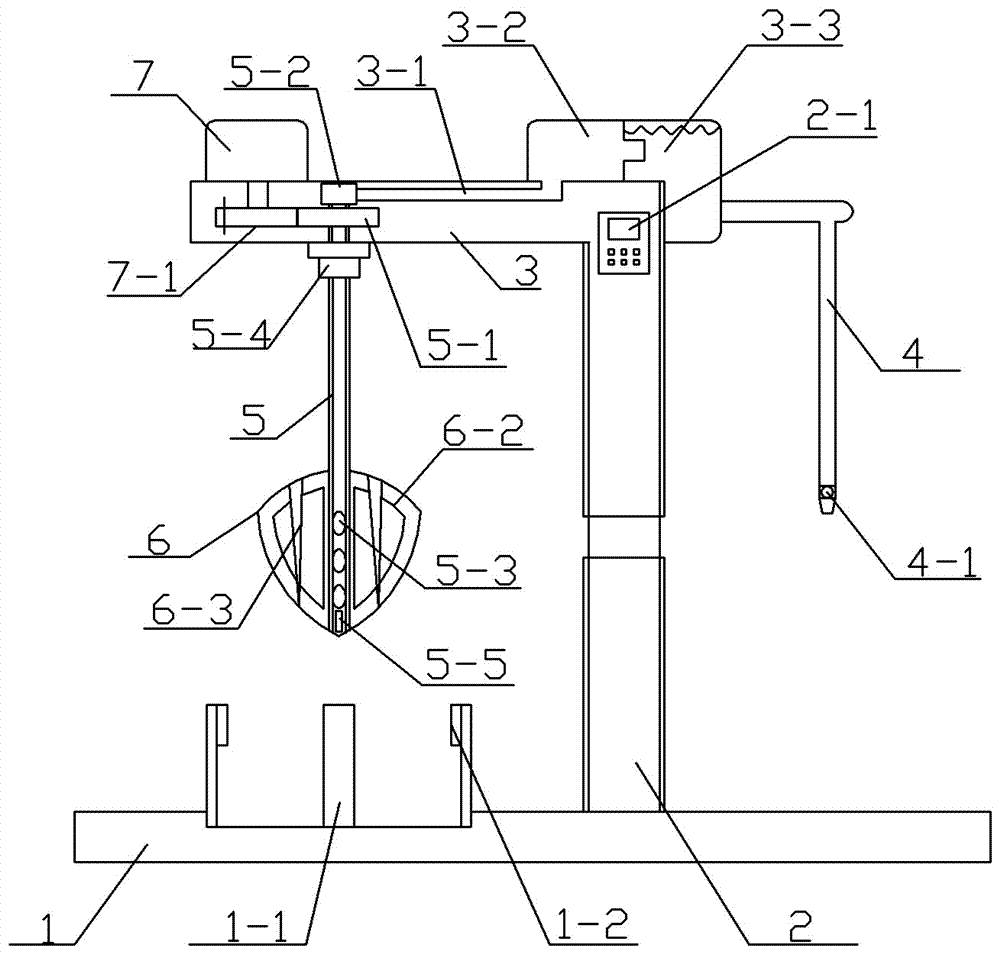

[0014] The reference signs in the drawings of the specification include: base 1, deck 1-1, heat-resistant rubber pad 1-2; electric control lifting support 2, miniature electric control platform 2-1; cantilever 3, extraction catheter 3-1 , extraction pump 3-2, asphalt storage bin 3-3; asphalt output pipe 4, squeeze switch 4-1; hollow shaft 5, driven gear 5-1, rotary seal 5-2, asphalt suction hole 5-3 , torque sensor 5-4, contact temperature sensor 5-5; stirring blade 6, heating module 6-2, ridge strip 6-3; servo motor 7, driving gear 7-1.

[0015] Below in conjunction with accompanying drawing and embodiment the technical scheme of the present invention is described in further detail: as figure 1 As shown, the present invention is a kind of rapid heating and extraction equipment for indoor testing asphalt, which includes a base 1, which is provided with a groove for accommodating an asphalt storage barrel, and four vertical clamping seats are uniformly welded on the peripheral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com