Diazinon coated slow-released granule preparation method

A slow-release granule and diazinon-encapsulated technology, which can be applied to botanical equipment and methods, insecticides, acaricides, etc., can solve the problems of low utilization rate and poor effect of diazinon original drug, and achieve good results. Effects of environmental protection, release slowing, and reduction of agricultural production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

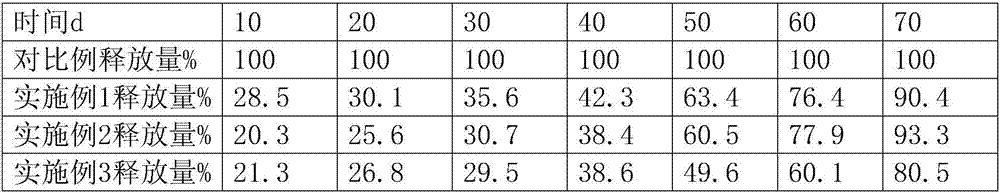

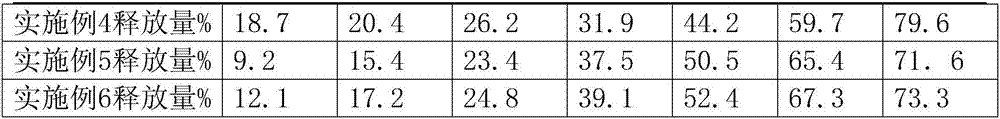

Examples

Embodiment 1

[0024] A kind of preparation method of diazinon-coated sustained-release granule

[0025] 1. Preparation of a suspension containing diazinon: add 10 g of diazinon to 55 g of water, and then ultrasonically disperse to obtain a suspension containing diazinon.

[0026] 2. Preparation of drug-loaded diatomite particles: first place 40g of dry diatomite particles in a closed container, pump air to make it in a vacuum state and then seal it, then inject the suspension containing diazinon into the container for 3 hours Finally, the vacuum device was opened, and the suspension of diazinon was poured into the pores of the diatomite particles by using the pressure difference between the atmospheric pressure and the vacuum device. After 18 minutes, it was freeze-dried to obtain the drug-loaded diatomite particles.

[0027] 3. Preparation of coating agent: Mix 18g of methylol ethylene urea resin and 7g of sulfonated paraffin evenly, then add 0.4g of calcium ricinoleate and 7g of acetonitr...

Embodiment 2

[0030] A kind of preparation method of diazinon-coated sustained-release granule

[0031] 1. Preparation of a suspension containing diazinon: add 10 g of diazinon into 46 g of water, and then ultrasonically disperse to obtain a suspension containing diazinon.

[0032] 2. Preparation of drug-loaded diatomite particles: first place 68g of dried diatomite particles in an airtight container, pump air to make it in a vacuum state and then seal it, then inject the suspension containing diazinon into the container for 2.5 After one hour, the vacuum device was opened, and the suspension of diazinon was poured into the pores of the diatomite particles by using the pressure difference between the atmospheric pressure and the vacuum device. After 20 minutes, the drug-loaded diatomite particles were obtained by freeze-drying.

[0033] 3. Preparation of coating agent: Mix 15g of polyvinyl alcohol urea phosphate and 10g of chlorinated paraffin evenly, then add 0.6g of epoxy soybean oil and ...

Embodiment 3

[0036] A kind of preparation method of diazinon-coated sustained-release granule

[0037] 1. Preparation of a suspension containing diazinon: add 10 g of diazinon into 22-67 g of water, and then disperse ultrasonically to obtain a suspension containing diazinon.

[0038] 2. Preparation of drug-loaded diatomite particles: first place 32g of dry diatomite particles in an airtight container, pump air to make it in a vacuum state and then seal it, then inject the suspension containing diazinon into the container for 2 hours Finally, the vacuum device was opened, and the suspension of diazinon was poured into the pores of the diatomite particles by using the pressure difference between the atmospheric pressure and the vacuum device. After 10 minutes, the drug-loaded diatomite particles were obtained by freeze-drying.

[0039] 3. Preparation of a compound containing diazinon: 2 g of diazinon, 15 g of pyrophyllite, 5 g of polyvinyl alcohol, 1 g of polyoxyethylene sorbitan monooleate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com