Preparation method and application of modified mesoporous hollow silica sphere adsorbent

A technology of hollow silicon and adsorbent, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as separation, purification and deep processing of products, increase the complexity of purification process, etc., and achieve unique physical Chemical properties, good monodispersity, high selectivity adsorption separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

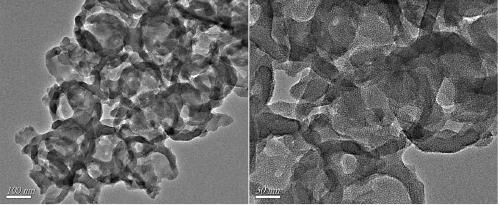

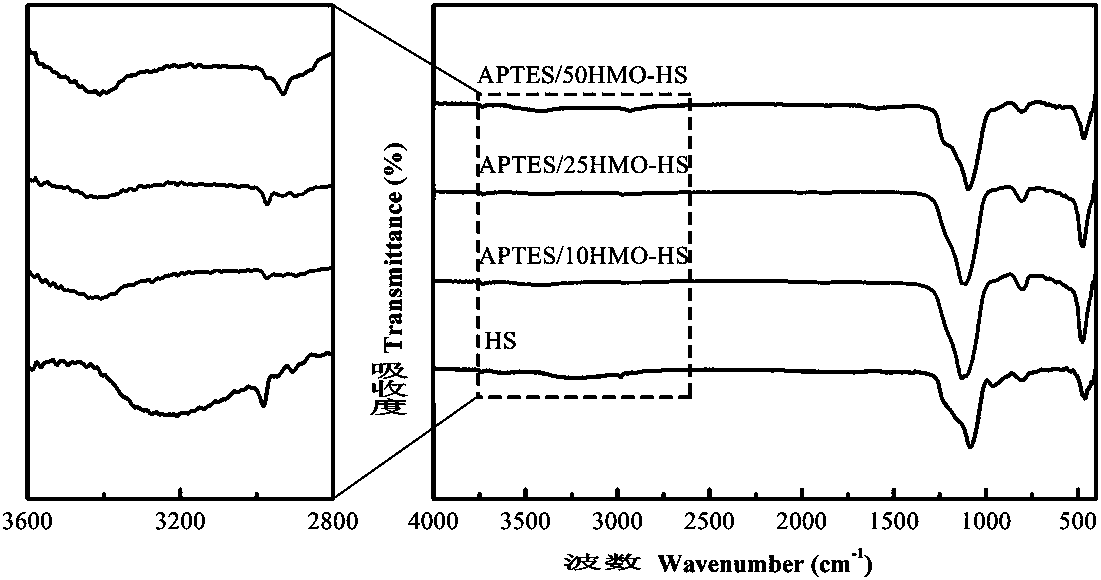

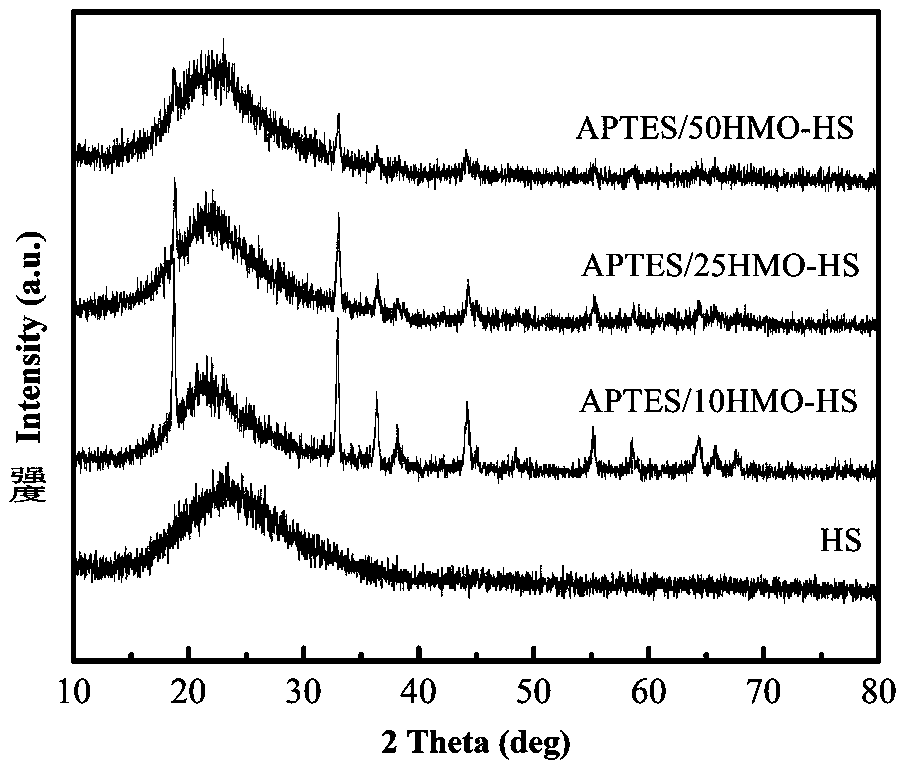

[0043] (1) Weigh 0.317g CTAB, dissolve it in a mixed solution of 33mL ethanol and 95mL deionized water, stir mechanically for 3 minutes, quickly add 1.92mL ammonia water, continue stirring for 50 minutes, and add 1.92mL TEOS dropwise. After stirring at 35 °C for 22 h, it was centrifuged and washed 3 times with ethanol. Then add 600mL of water and stir at 50°C for 10h. Filter with suction, wash, and place in a muffle furnace for calcination at 500°C for 4 hours to obtain mesoporous hollow silica spheres (HS).

[0044] (2) Weigh LiCl·H according to the ratio of Li:Mn:Si=1:1:10, 1:1:25, 1:1:50 2 O and MnCl 2 4H 2 O, dissolved in 80mL ethanol, made into lithium / manganese ethanol solutions with different concentrations. Take 0.502g of mesoporous hollow silicon spheres and place them in the above lithium / manganese ethanol solutions with different concentrations, shake in a water bath for 20 hours, dry at 70°C, and place them in a muffle furnace at 520°C for calcination for 4 hou...

Embodiment 2

[0048] (1) Weigh 0.320g CTAB, dissolve it in a mixed solution of 35mL ethanol and 98mL deionized water, stir mechanically for 7min, quickly add 2mL ammonia water, continue stirring for 60min, and add 2mL TEOS dropwise. After stirring at 35 °C for 24 h, it was centrifuged and washed 3 times with ethanol. Then add 700mL of water and stir at 80°C for 15h. Suction filtration, washing, and calcination in a muffle furnace at 530° C. for 5 hours to obtain mesoporous hollow silica spheres (HS).

[0049] (2) Weigh LiCl·H according to the ratio of Li:Mn:Si=1:1:10, 1:1:25, 1:1:50 2 O and MnCl 2 4H 2 O, dissolved in 90mL ethanol, made into lithium / manganese ethanol solutions with different concentrations. Take 0.514g of mesoporous hollow silicon spheres and place them in the above lithium / manganese ethanol solutions with different concentrations, shake in a water bath for 22 hours, dry at 75°C, and place them in a muffle furnace at 540°C for calcination for 5 hours. After the reactio...

Embodiment 3

[0053] (1) Weigh 0.324g CTAB, dissolve it in a mixed solution of 37mL ethanol and 102mL deionized water, stir mechanically for 8min, then quickly add 2.05mL ammonia water, continue stirring for 70min, and add 2.07mL TEOS dropwise. After stirring at 35 °C for 26 h, it was centrifuged and washed 3 times with ethanol. Then add 800mL of water and stir at 65°C for 14h. Suction filtration, washing, and calcination in a muffle furnace at 550° C. for 5 h to obtain mesoporous hollow silica spheres (HS).

[0054] (2) Weigh LiCl·H according to the ratio of Li:Mn:Si=1:1:10, 1:1:25, 1:1:50 2 O and MnCl 2 4H 2 O, dissolved in 120mL ethanol, made into lithium / manganese ethanol solutions with different concentrations. Take 0.520g of mesoporous hollow silicon spheres and place them in the above-mentioned lithium / manganese ethanol solutions with different concentrations, shake in a water bath for 24 hours, dry at 75°C, and place them in a muffle furnace at 550°C for calcination for 5 hours....

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com