Cerium modified supported type nickel-based catalyst as well as preparation method and application thereof

A nickel-based catalyst, supported technology, applied in the preparation of amino compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of increasing the difficulty of recycling precious metal catalysts, complicated preparation process of modified catalysts, etc. and low cost of use, good product quality, and the effect of overcoming side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

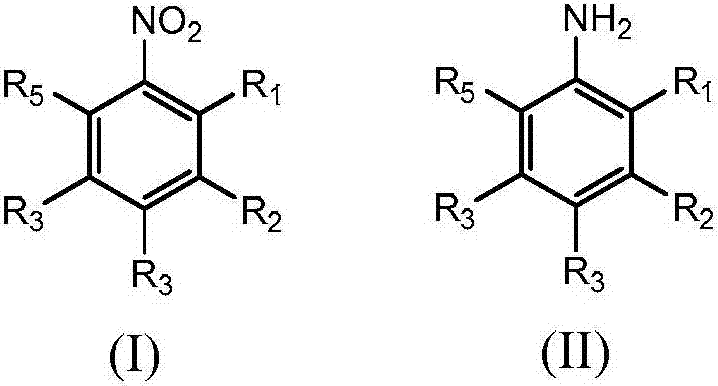

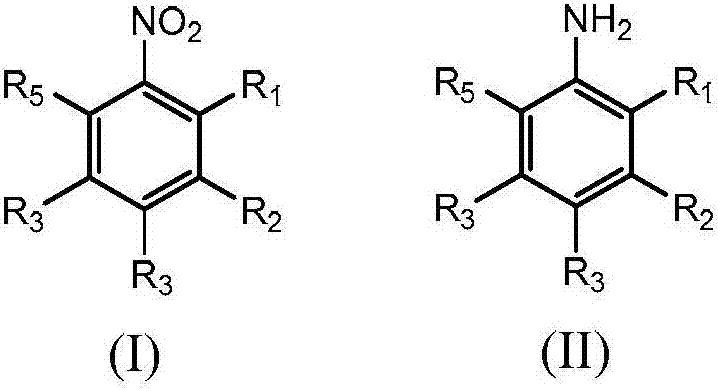

Image

Examples

Embodiment 1

[0029] Weigh 20 grams of titanium dioxide carrier, impregnate it in an equal volume of mixed aqueous solution of nickel nitrate and cerium nitrate (dissolve 5 grams of nickel nitrate and 0.5 grams of cerium nitrate in 20 mL of aqueous solution), immerse for 4 hours, and dry at 110 ° C for 3 hours Afterwards, calcining at 500°C for 4 hours, and then reducing in hydrogen flow at 400°C for 2 hours to obtain a cerium-modified supported nickel-based catalyst.

Embodiment 2

[0031] Weigh 20 grams of titanium dioxide carrier, impregnate it in an equal volume of mixed aqueous solution of nickel nitrate and cerium nitrate (dissolve 10 grams of nickel nitrate and 0.5 grams of cerium nitrate in 20 mL of aqueous solution), immerse for 6 hours, and dry at 120 ° C for 2 hours Afterwards, it was calcined at 600°C for 3 hours, and then reduced in a hydrogen flow at 450°C for 2 hours to obtain a cerium-modified supported nickel-based catalyst.

Embodiment 3

[0033] Weigh 20 grams of titanium dioxide carrier, impregnate it in an equal volume of mixed aqueous solution of nickel nitrate and cerium nitrate (dissolve 2 grams of nickel nitrate and 0.2 grams of cerium nitrate in 20 mL of aqueous solution), immerse for 3 hours, and dry at 90 ° C for 4 hours Afterwards, it was calcined at 400°C for 6 hours, and then reduced in a hydrogen flow at 550°C for 1 hour to obtain a cerium-modified supported nickel-based catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com