Desiliconized fly ash and preparation method and application thereof

A technology for fly ash and high-alumina fly ash, which is applied in alumina/aluminum hydroxide and other directions, can solve the problems of low desiliconization efficiency, large alumina circulation volume, and high equipment requirements, and is convenient for large-scale promotion and application. , Reduce the cost of equipment use, the effect of mild implementation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

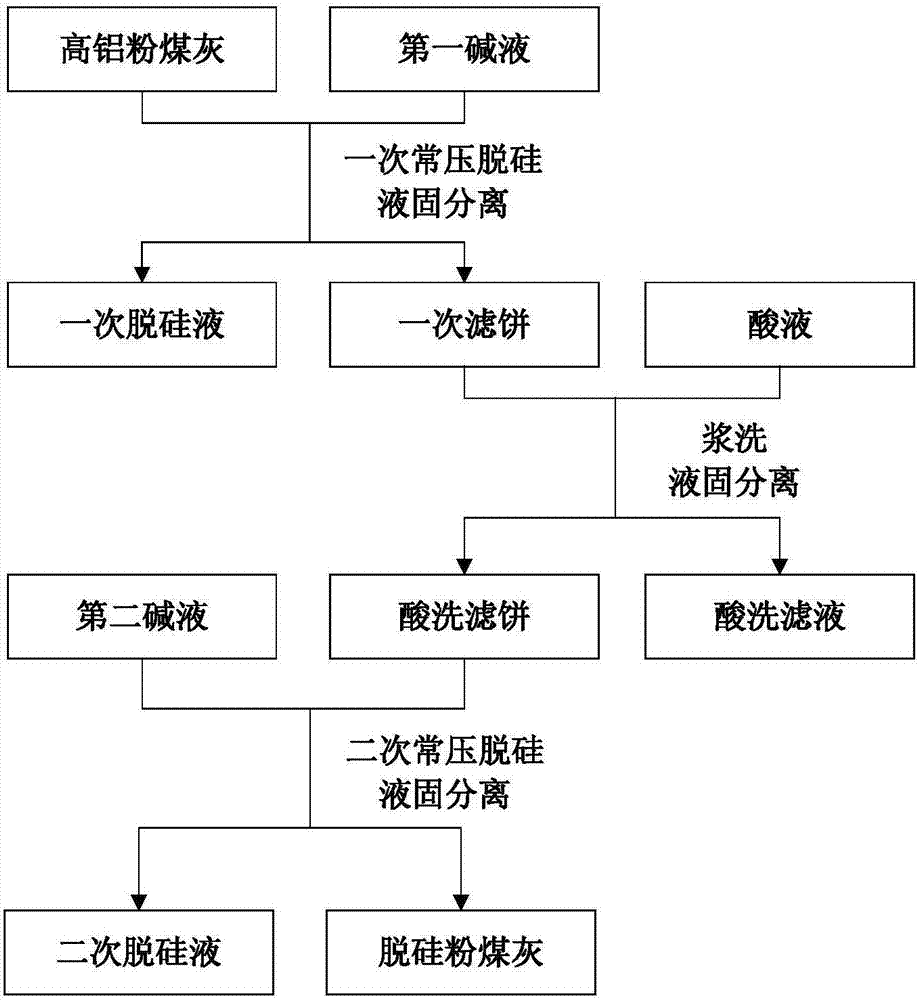

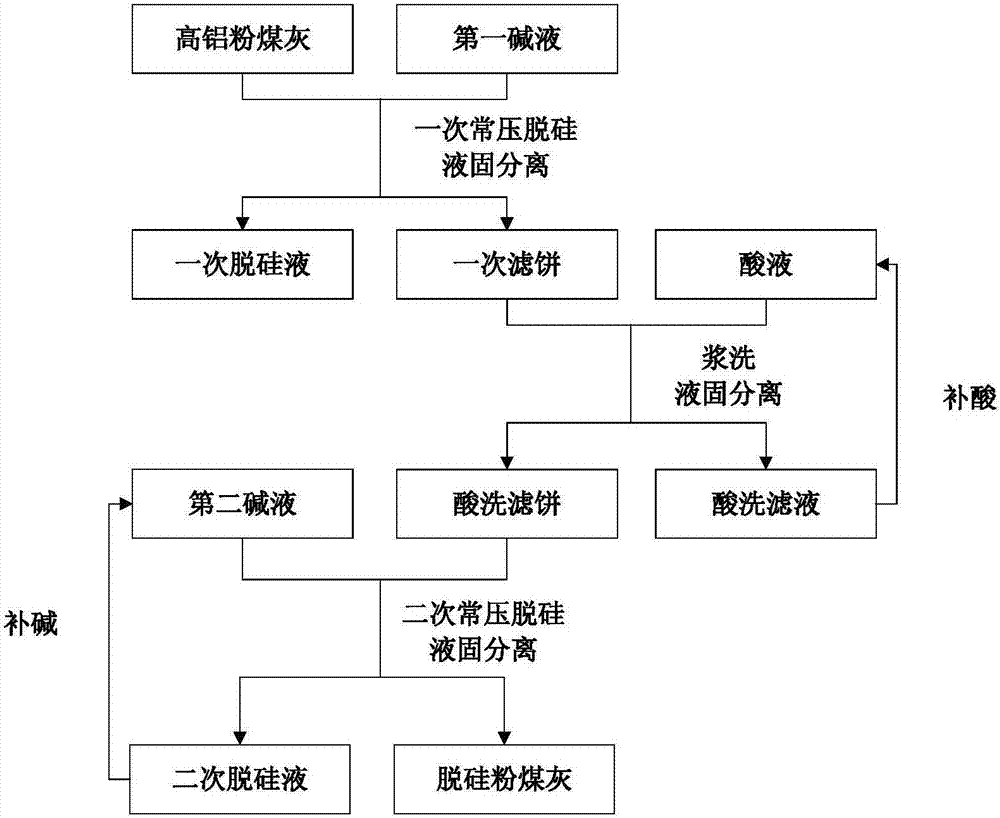

[0029] like figure 1 As shown, the preparation method of the desiliconized fly ash provided in this embodiment comprises the following steps:

[0030] Mix 100g of high-alumina fly ash (alumina content of 48.21wt%, silica content of 39.22wt%, aluminum-silicon ratio of 1.23) and 280mL of sodium hydroxide solution (concentration of 12wt%) in a normal pressure reactor React in medium for about 1 hour, control the reaction temperature to maintain at about 85°C, vacuum filter after the reaction is completed, and obtain the primary desiliconization liquid in the liquid phase and the primary filter cake in the solid phase, and wash the primary filter cake at a temperature of about 105°C Under drying, the aluminum-silicon ratio of the primary filter cake was measured to be 2.19;

[0031] The primary filter cake was slurried with sulfuric acid solution, according to the liquid-solid mass ratio of 4, the temperature was 90°C, the sulfuric acid concentration was 13.5wt%, and after slurry...

Embodiment 2

[0034] like figure 1 As shown, the preparation method of the desiliconized fly ash provided in this embodiment comprises the following steps:

[0035] Mix 100g of high-alumina fly ash (alumina content of 48.21wt%, silica content of 39.22wt%, and aluminum-silicon ratio of 1.23) with 300mL of sodium hydroxide solution (concentration of 10wt%) in an atmospheric pressure reactor React in medium for about 1 hour, control the reaction temperature to maintain at about 95°C, carry out vacuum filtration after the reaction is completed, and obtain the primary desiliconization liquid in the liquid phase and the primary filter cake in the solid phase, and wash the primary filter cake at a temperature of about 105°C Under drying, the aluminum-silicon ratio of the primary filter cake was measured to be 2.22;

[0036] The primary filter cake was slurried with sulfuric acid solution, according to the liquid-solid mass ratio of 5, the temperature was 95 ° C, and the sulfuric acid concentratio...

Embodiment 3

[0039] like figure 1 As shown, the preparation method of the desiliconized fly ash provided in this embodiment comprises the following steps:

[0040] Mix 100g of high-alumina fly ash (alumina content of 48.21wt%, silica content of 39.22wt%, aluminum-silicon ratio of 1.23) with 300mL of sodium hydroxide solution (concentration of 13.5wt%) and react at normal pressure React in the container for about 2 hours, control the reaction temperature to maintain at about 94°C, and vacuum filter after the reaction is completed to obtain the primary desiliconization liquid in the liquid phase and the primary filter cake in the solid phase, and wash the primary filter cake at about 105°C Drying at high temperature, the aluminum-silicon ratio of the primary filter cake was measured to be 2.21;

[0041] The primary filter cake was slurried with hydrochloric acid solution, according to the liquid-solid mass ratio of 3.5, the temperature was 92°C, and the concentration of hydrochloric acid wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com