Ir(III) complex, preparation method of Ir(III) complex, and application of Ir(III) complex to preparation of electroluminescent device

A technology of electroluminescent devices and complexes, applied in the direction of electric solid devices, electrical components, luminescent materials, etc., can solve the problems that have not yet found high-efficiency and standard red and blue light materials, achieve improved luminous brightness, good application prospects, Stable and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1I

[0052] Example 1 Ir (III) complex (Ir-Fppy 2 -phq) preparation

[0053] 1. The preparation method of the Ir(III) complex is as follows:

[0054] (1) Synthetic intermediate [Ir(Fppy) 2 Cl] 2 :

[0055] IrCl 3 ·3H 2 O 0.604g (1.7mmol) and Fppy 0.719g (3.7mmol) were added to the mixed solution of 30ml ethylene glycol ether / water (v:v=3:1), N 2 protection, 120°C, react for 24h, add 10ml H 2 O to adjust the polarity, filter, and wash the filter cake with a small amount of EtOH, then with a small amount of ether, and finally with a large amount of n-hexane, and dry to obtain a yellow solid with a yield of 40%. The product was directly put into the next reaction without further post-processing.

[0056] The structural formula of Fppy ligand is as formula (II):

[0057]

[0058] [Ir(Fppy) 2 Cl] 2 The structure of is as shown in formula (III):

[0059]

[0060] (2) Synthesis of complex Ir-Fppy 2 -phq:

[0061] [Ir(Fppy) 2 Cl] 2 0.12g (0.1mmol) and 8-hydroxyquinol...

Embodiment 2

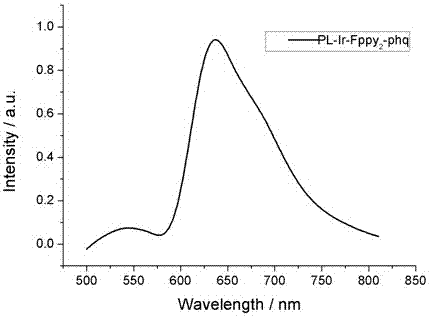

[0067] Example 2 Photoluminescence test of Ir(III) complexes

[0068] A photoluminescence test was performed on the Ir(III) complex prepared in Example 1 (using an EDINBURGH FLS980 fluorometer, with an excitation wavelength of 300 nm).

[0069] Test results such as figure 1 shown. The photoluminescence test shows that the Ir(III) complex with the structure of formula (I) emits red light in the wavelength range of 600-750nm.

Embodiment 3

[0070] Example 3 Preparation of electroluminescent device

[0071] 1. Preparation of vapor-deposited multilayer electroluminescent devices:

[0072] The Ir-Fppy 2 -phq complex and host material 4,4'-bis(carbazol-9-yl)biphenyl (CBP) doped evaporation, according to CBP:Ir-Fppy 2 The mass ratio of -phq complex is 100:6, as the light-emitting layer EML; all materials are prepared by evaporation method on the ITO glass substrate with a multi-layer structure electroluminescent device, which is Ir-Fppy 2 -phq complex LED devices.

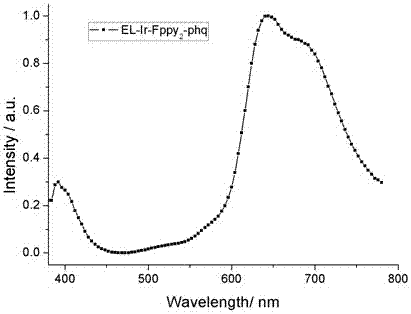

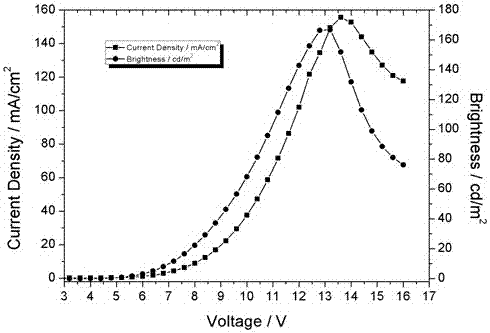

[0073] 2. Performance testing of electroluminescent devices

[0074] (1) Conduct electroluminescence test on the prepared electroluminescent device (use PR-735 spectrum test system to test). The electroluminescence device emits an electroluminescence spectrum similar to the photoluminescence spectrum, and the test results are as follows: Figure 2~3 shown.

[0075] It can be seen from the figure that the device produces electroluminescence in the 600...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com