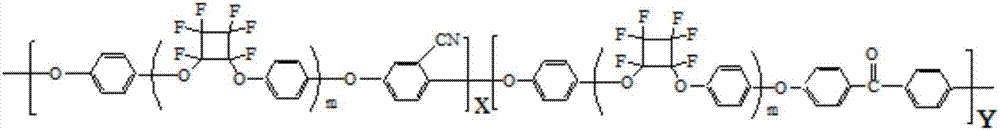

Polyaryletherketone containing nitrile group and perfluorocyclobutyl aryl-ether structure and synthetic method thereof

A technology of perfluorocyclobutyl aryl ether and polyaryl ether ketone, which is applied to organic insulators, plastic/resin/wax insulators, electrical components, etc., can solve the problems of complex preparation process requirements, reducing cable reliability, and increasing product costs. , to achieve the effect of multiple cross-linking points, low production cost, and improved physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

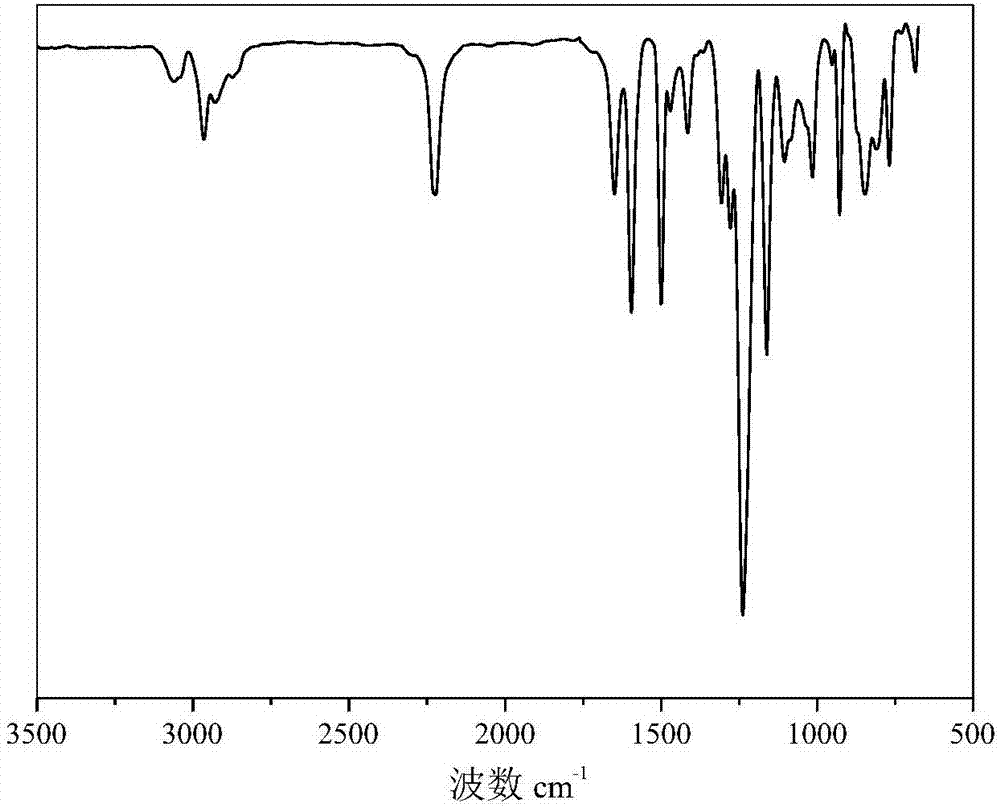

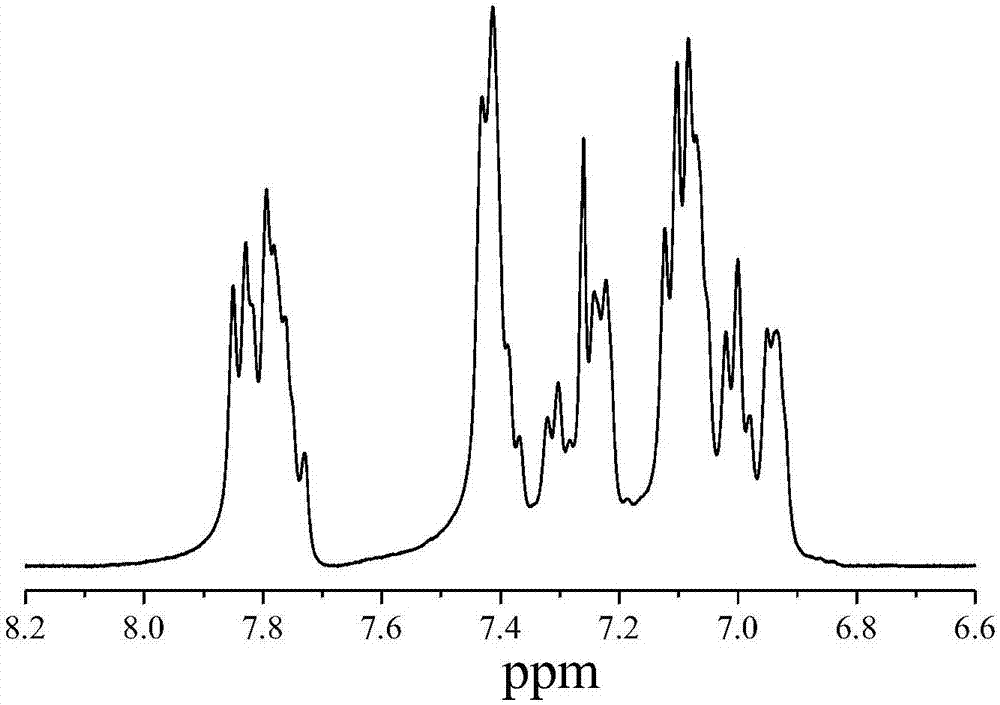

Embodiment 1

[0034] Synthesis of polyaryl ether ketone containing nitrile group and perfluorocyclobutyl aryl ether structure: 49.0000g (20mmol) perfluorocyclobutyl aryl ether phenol polymer, 0.69g (4mmol) 2,5-dichloro Benzonitrile, 3.49g (16mmol) 4,4'-difluorobenzophenone, toluene 80mL, DMAc100mL, 5.53g (40mmol) potassium carbonate, in 1mL / s N 2 Flow down at 140°C for 3 hours, then raise the temperature to 170°C for 20 hours, immediately pour the reaction solution into deionized water for precipitation under stirring, and filter. Soak the filtered precipitate with deionized water, change the water every 3 hours, filter after 24 hours, and dry the precipitate in a vacuum oven at 80°C for 10 hours to obtain a structure containing a nitrile group and a perfluorocyclobutyl aryl ether The polyaryletherketone sample was analyzed by GPC: Mn=53339, PDI=2.85, and the yield was 96%. Its synthetic route:

[0035]

Embodiment 2

[0037]Synthesis of polyaryl ether ketone containing nitrile group and perfluorocyclobutyl aryl ether structure: 49.0000g (20mmol) perfluorocyclobutyl aryl ether phenol polymer, 1.03g (6mmol) 2,5-dichloro Benzonitrile, 3.05g (14mmol) 4,4'-difluorobenzophenone, toluene 80mL, DMAc100mL, 5.53g (40mmol) potassium carbonate, in 1mL / s N 2 Flow down at 140°C for 3 hours, then raise the temperature to 170°C for 20 hours, immediately pour the reaction solution into deionized water for precipitation under stirring, and filter. Soak the filtered precipitate with deionized water, change the water every 3 hours, filter after 24 hours, and dry the precipitate in a vacuum oven at 80°C for 10 hours to obtain a structure containing a nitrile group and a perfluorocyclobutyl aryl ether The polyaryletherketone sample was analyzed by GPC: Mn = 54436, PDI = 2.95, and the yield was 97.5%, and the results of DSC research showed that the glass transition temperature of the polyaryletherketone sample pr...

Embodiment 3

[0039] Synthesis of polyaryl ether ketone containing nitrile group and perfluorocyclobutyl aryl ether structure: 49.0000g (20mmol) perfluorocyclobutyl aryl ether phenol polymer, 1.37g (8mmol) 2,5-dichloro Benzonitrile, 2.61g (12mmol) 4,4'-difluorobenzophenone, toluene 80mL, DMAc100mL, 5.53g (40mmol) potassium carbonate, in 1mL / s N 2 Flow down at 140°C for 3 hours, then raise the temperature to 170°C for 20 hours, immediately pour the reaction solution into deionized water for precipitation under stirring, and filter. Soak the filtered precipitate with deionized water, change the water every 3 hours, filter after 24 hours, and dry the precipitate in a vacuum oven at 80°C for 10 hours to obtain a structure containing a nitrile group and a perfluorocyclobutyl aryl ether The polyaryletherketone sample was analyzed by GPC: Mn=52478, PDI=2.75, and the yield was 96.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com