Halogen-free flame-resistant polypropylene composition containing triazine expansion flame retardants and preparation of composition

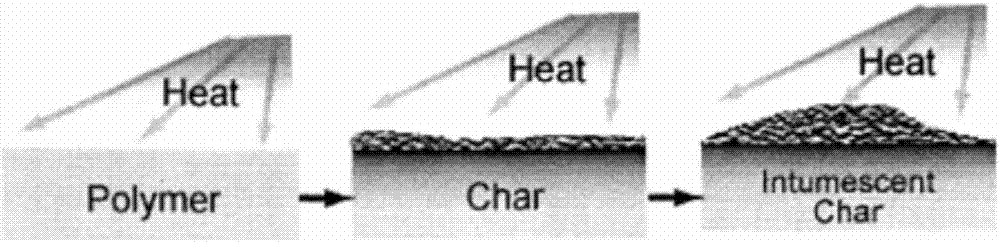

A technology of intumescent flame retardant and flame retardant polypropylene, applied in the field of polymer materials, can solve the problems of easy reaction with ammonium polyphosphate, reduced mechanical properties of flame retardant polypropylene, easy migration, etc., and achieves good mechanical properties and flame retardant. High efficiency and the effect of improving flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

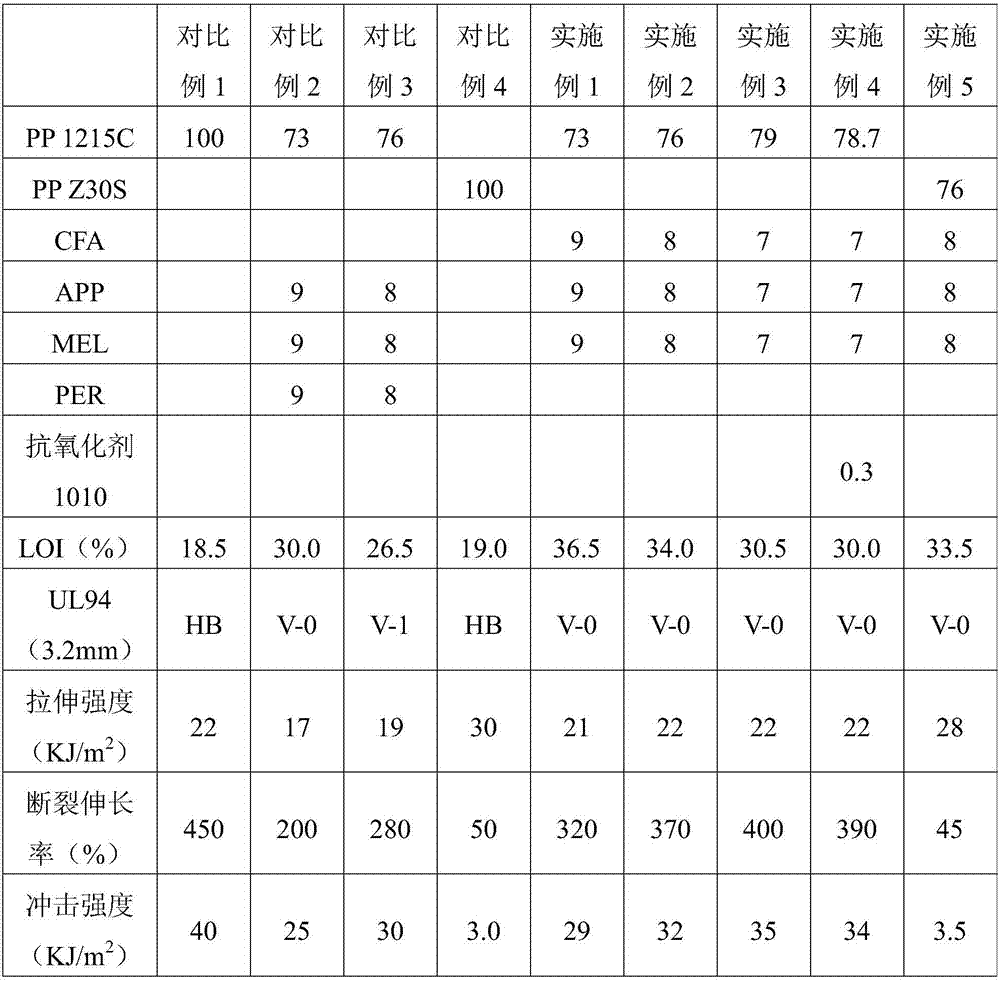

[0027] Mix 73 parts of PP 1215C, 9 parts of CFA, 9 parts of MEL and 9 parts of APP in a high-speed mixer for 2 minutes by weight, and then add them to the main hopper of a co-rotating parallel twin-screw extruder at 190-220 ° C Melting and kneading at a certain temperature, the obtained melt is extruded by a twin-screw extruder, cooled in a water tank, introduced into a pelletizer for pelletizing operation, and the obtained pellets are the high-performance halogen-free flame-retardant PP composition.

Embodiment 2

[0029] Mix 76 parts of PP 1215C, 8 parts of CFA, 8 parts of MEL and 8 parts of APP in a high-speed mixer for 2 minutes by weight, and then add them to the main hopper of the co-rotating parallel twin-screw extruder, at 190-220 ° C Melting and kneading at a certain temperature, the obtained melt is extruded by a twin-screw extruder, cooled in a water tank, introduced into a pelletizer for pelletizing operation, and the obtained pellets are the high-performance halogen-free flame-retardant PP composition.

Embodiment 3

[0031] Mix 79 parts of PP 1215C, 7 parts of CFA, 7 parts of MEL and 7 parts of APP in a high-speed mixer for 2 minutes by weight, and then add them to the main hopper of a co-rotating parallel twin-screw extruder at 190-220 ° C Melting and kneading at a certain temperature, the obtained melt is extruded from a twin-screw extruder, cooled in a water tank, introduced into a pelletizer for pelletizing operation, and the obtained pellets are the high-performance halogen-free flame-retardant PP composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com