Super-hydrophobic oleophobic coating, preparation method thereof and use method

A super-hydrophobic and oleophobic technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor wear resistance and corrosion resistance, inability to use on a large scale, harsh conditions, etc. Simple and quick to use, excellent superhydrophobicity and oleophobicity, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of superhydrophobic oleophobic fluorocarbon coating of the present invention

[0030] 1. Composition

[0031] Component A: 2g of E-51 epoxy resin, 4g of fluorinated graphite, 0.5g of ammonium carbonate, 0.5g of polyoxyethylene ether, 30mL of ethanol; the fluorine content of fluorinated graphite is 50%, and the average particle size of fluorinated graphite particles is The diameter is 100nm.

[0032] Component B: 0.6 g of aminoethylpiperazine, 5 mL of ethanol.

[0033] 2. Preparation method

[0034] Preparation of Component A: First, E-51 epoxy resin (2g) was dissolved in ethanol (5mL) to obtain an ethanol solution of epoxy resin; graphite fluoride (4g) was dispersed in ethanol (25mL), and Use an electromagnetic stirrer to disperse at a speed of 600r / min for 20min, then add ammonium carbonate (0.5g) and polyoxyethylene ether (0.5g) to the fluorinated graphite dispersion, and then use an electromagnetic stirrer to disperse at a speed of 600r / min 20min to obtain...

Embodiment 2

[0039] The difference between the superhydrophobic and oleophobic fluorocarbon coating of Example 2 and Example 1 is only that the graphite fluoride content in component A is 2 g, and the rest of the composition and preparation method are the same.

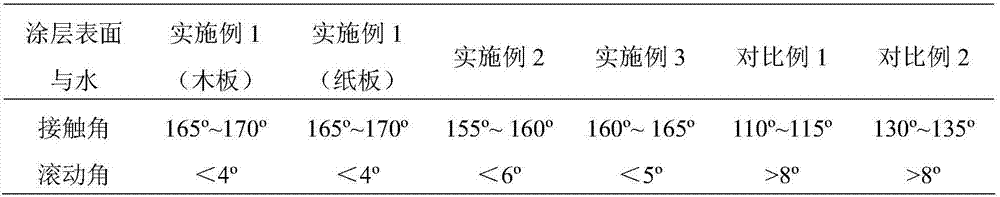

[0040] Referring to Example 1, component A and component B were evenly mixed and coated on a wooden board, and the coating sample obtained after curing was subjected to a performance test, and the test results are shown in Table 1.

Embodiment 3

[0042] The difference between the superhydrophobic and oleophobic fluorocarbon coating of Example 3 and Example 1 is only that the fluorine content of graphite fluoride in component A is 30%, and the rest of the composition and preparation method are the same.

[0043] Referring to Example 1, component A and component B were evenly mixed and coated on a wooden board, and the coating sample obtained after curing was subjected to a performance test, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com