High-durability floor wax and preparation method thereof

A technology of durability and floor wax, applied in polishing compositions containing abrasives, etc., can solve the problem of poor durability of floor wax, and achieve the effects of enhancing film-forming properties, improving smoothness, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

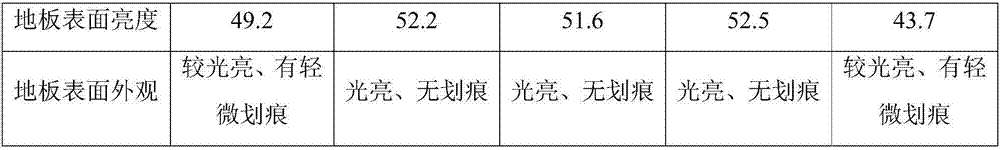

Examples

Embodiment 1

[0031] A high-durability floor wax, the components and parts by weight of the high-durability floor wax are: 18 parts of paraffin wax, 6 parts of beeswax, 8 parts of spermaceti, 4 parts of nano silicon dioxide, silane coupling agent 0.2 parts, 4 parts of nano-zinc oxide, 0.3 parts of polyvinyl acetate emulsion, 0.3 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 4 parts of hydroxyethyl cellulose, 3 parts of lemon oil, 4 parts of propylene glycol, polysiloxane-polymer 0.6 parts of ether copolymer emulsion, 3 parts of acrylic resin.

[0032] The preparation method of above-mentioned high durability floor wax comprises the following steps:

[0033] (1) Add paraffin, beeswax, spermaceti and appropriate amount of water into the reaction kettle, heat up to 80-90°C while stirring, stir and melt until mixed evenly, and set aside;

[0034] (2) Add nano-silica and nano-zinc oxide into the mixer, and after preliminary mixing, add silane coupling agent and polyvinyl acetate ...

Embodiment 2

[0038] A high-durability floor wax, the components and parts by weight of the high-durability floor wax are: 26 parts of paraffin wax, 8 parts of beeswax, 14 parts of spermaceti, 8 parts of nano silicon dioxide, silane coupling agent 0.4 parts, 6 parts of nano-zinc oxide, 0.5 parts of polyvinyl acetate emulsion, 0.6 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 6 parts of hydroxyethyl cellulose, 5 parts of lemon oil, 6 parts of propylene glycol, polysiloxane-polymer 0.8 parts of ether copolymer emulsion, 5 parts of acrylic resin.

[0039] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0041] A high-durability floor wax, the components and parts by weight of the high-durability floor wax are: 22 parts of paraffin wax, 7 parts of beeswax, 11 parts of spermaceti, 6 parts of nano silicon dioxide, silane coupling agent 0.3 parts, 5 parts of nano-zinc oxide, 0.4 parts of polyvinyl acetate emulsion, 0.5 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 5 parts of hydroxyethyl cellulose, 4 parts of lemon oil, 5 parts of propylene glycol, polysiloxane-polymer 0.7 parts of ether copolymer emulsion, 4 parts of acrylic resin.

[0042] The preparation method of this embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com