Special adhesive resin for polyvinyl chloride corrosion-resistant steel tube with barrier property and preparation method thereof

A technology of polyvinyl chloride and anti-corrosion steel pipe, applied in the direction of epoxy resin glue, graft polymer adhesive, adhesive, etc., can solve the problems of bonding resin performance, affecting application, etc., and achieve long service life and good elasticity and toughness, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

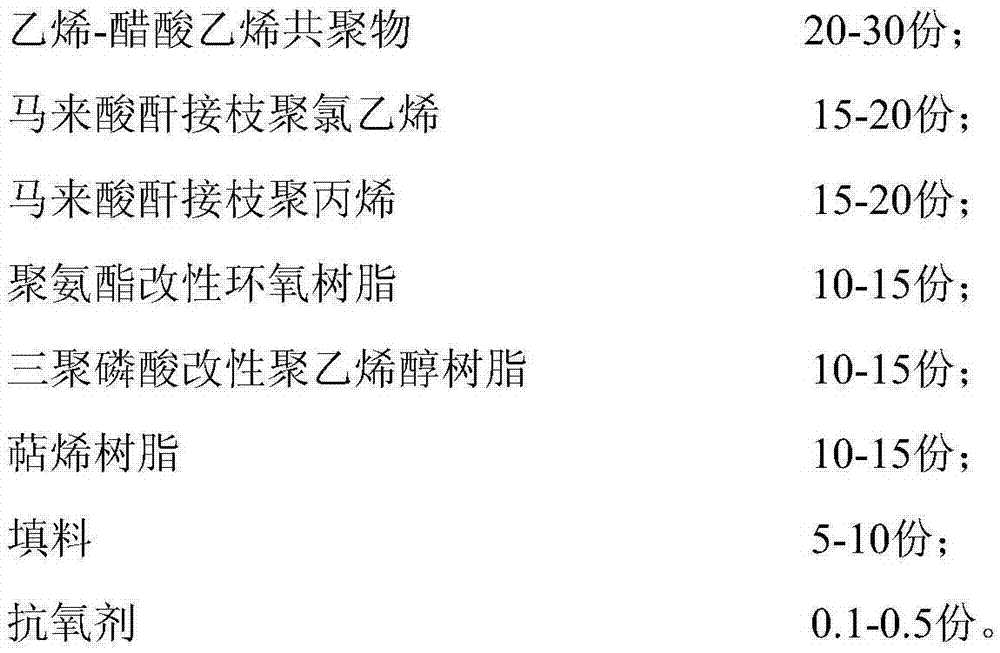

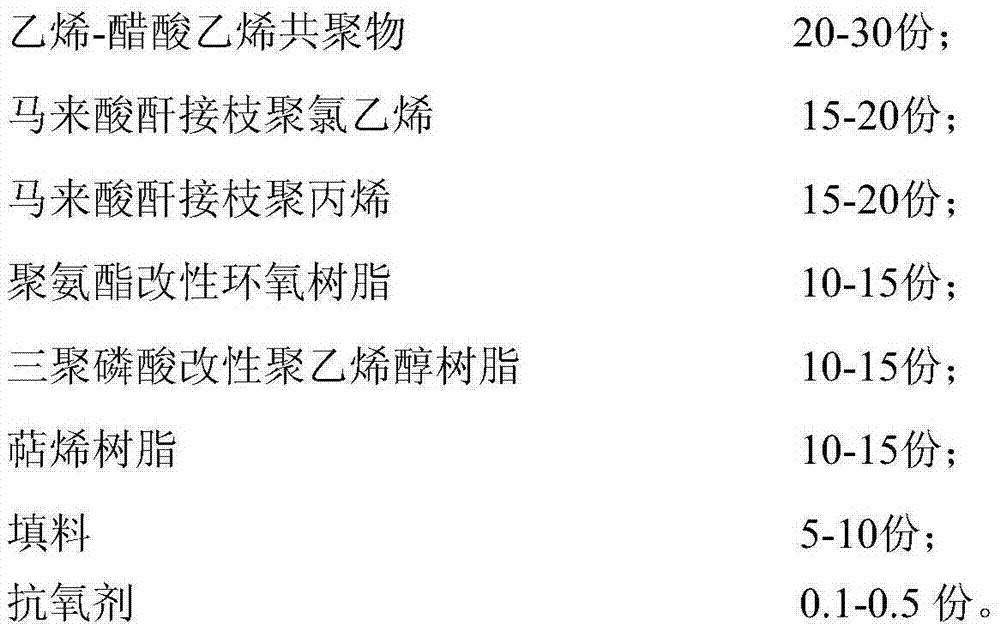

[0038] A special adhesive resin for polyvinyl chloride anti-corrosion steel pipes, comprising the following components in parts by mass: 30 parts of ethylene-vinyl acetate copolymer, 15 parts of maleic anhydride grafted polyvinyl chloride, and 15 parts of maleic anhydride grafted polypropylene 10 parts, 10 parts of polyurethane modified epoxy resin, 10 parts of tripolyphosphoric acid modified polyvinyl alcohol resin, 10 parts of terpene resin, 10 parts of filler talcum powder, and 0.5 part of antioxidant 1010.

[0039] Firstly, the ethylene-vinyl acetate copolymer, maleic anhydride-grafted polyvinyl chloride, and maleic anhydride-grafted polypropylene were oil-extended at 60° C. for 50 minutes according to the ratio. Then add antioxidant 1010, knead evenly in a kneader at high speed, and set the temperature at 180°C. Then add polyurethane modified epoxy resin, tripolyphosphoric acid modified polyvinyl alcohol resin, terpene resin and filler in turn, and continue to knead evenl...

Embodiment 2

[0041]A special adhesive resin for polyvinyl chloride anti-corrosion steel pipes, comprising the following components in parts by mass: 20 parts of ethylene-vinyl acetate copolymer, 20 parts of maleic anhydride grafted polyvinyl chloride, and 15 parts of maleic anhydride grafted polypropylene 10 parts of polyurethane modified epoxy resin, 10 parts of tripolyphosphoric acid modified polyvinyl alcohol resin, 10 parts of terpene resin, 5 parts of filler light calcium carbonate, and 0.1 part of antioxidant BHT.

[0042] Firstly, ethylene-vinyl acetate copolymer, maleic anhydride grafted polyvinyl chloride, and maleic anhydride grafted polypropylene were subjected to oil extension treatment at 70° C. for 40 minutes according to the ratio. Then add antioxidant BHT, knead evenly in a kneader at high speed, and set the temperature at 190°C. Add polyurethane-modified epoxy resin, tripolyphosphoric acid-modified polyvinyl alcohol resin, terpene resin and filler in sequence, and then kne...

Embodiment 3

[0044] A special adhesive resin for polyvinyl chloride anti-corrosion steel pipes, comprising the following components in parts by mass: 30 parts of ethylene-vinyl acetate copolymer, 15 parts of maleic anhydride grafted polyvinyl chloride, and 20 parts of maleic anhydride grafted polypropylene 10 parts, 10 parts of polyurethane modified epoxy resin, 10 parts of tripolyphosphoric acid modified polyvinyl alcohol resin, 10 parts of terpene resin, 5 parts of filler silica, and 0.3 part of antioxidant 1010.

[0045] Firstly, the ethylene-vinyl acetate copolymer, maleic anhydride grafted polyvinyl chloride, and maleic anhydride grafted polypropylene are subjected to oil extension treatment at 60-70°C for 45 minutes according to the proportion. Then add antioxidant 1010, knead evenly in a kneader at high speed, and set the temperature at 185°C. Add polyurethane-modified epoxy resin, tripolyphosphoric acid-modified polyvinyl alcohol resin, terpene resin and fillers in sequence, and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com