Reflective film with high diffuse reflectivity and preparation method thereof

A reflective film and diffuse reflection technology, applied in the field of reflective film with high diffuse reflectivity and its preparation, can solve the problems of uneven light and dark, and the backlight module is easy to produce shadows, etc. Effects of size, improved brightness and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

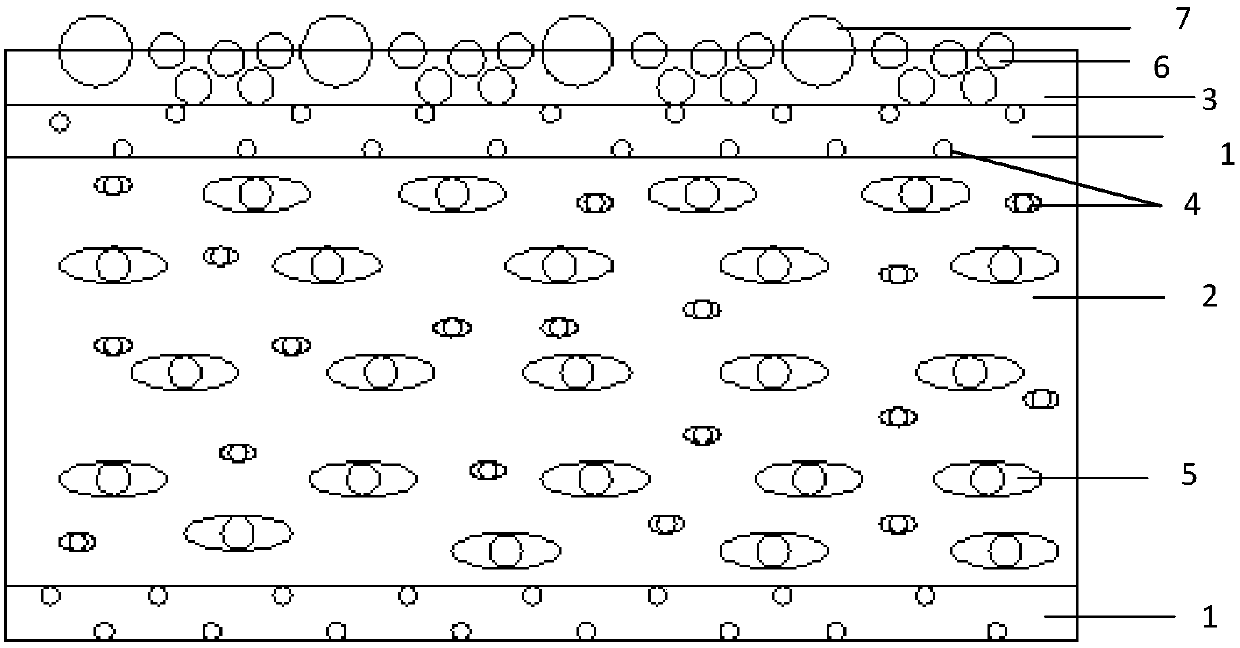

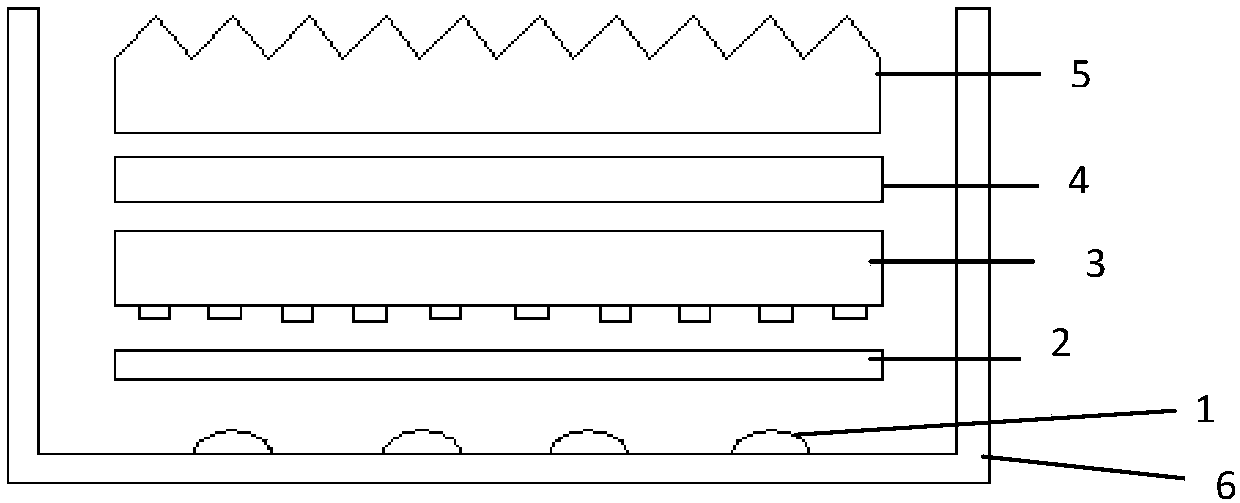

Method used

Image

Examples

Embodiment 1

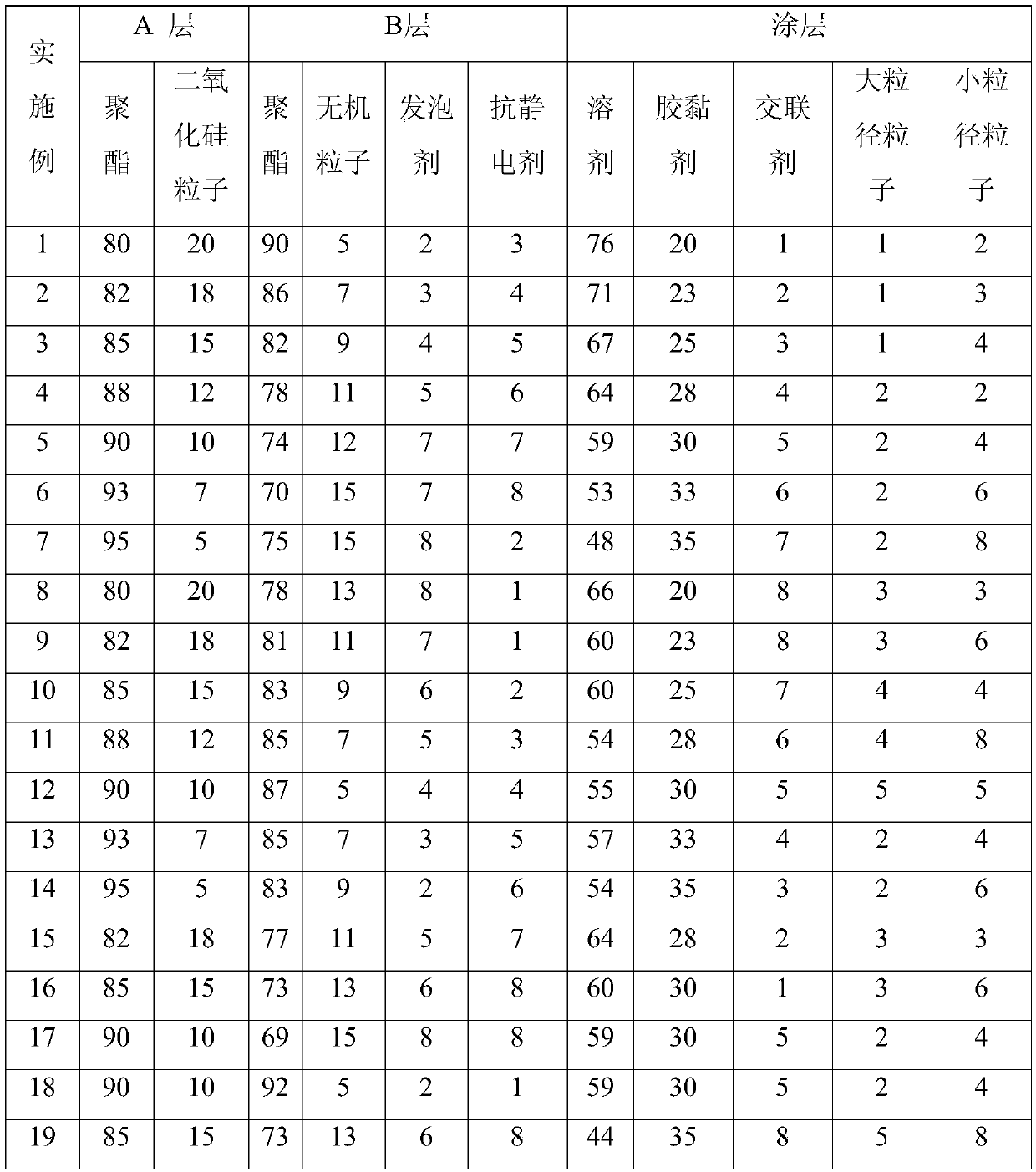

[0049] In the reflective film with high diffuse reflectivity provided by the present invention, the ratio of layer A is 80% of PET chips and 20% of silicon dioxide particles. The ratio of layer B is 90% PET chips, 5% rutile TiO 2 , 2% cyclic olefin copolymer resin, 3% antistatic agent. The coating ratio is 76% solvent (butanone: ethyl acetate = 1:2), 20% acrylate adhesive, 1% aliphatic polyisocyanate, 1% polystyrene particles with a particle size of 15-20 μm, 2% polystyrene particles with a particle size of 5-10 μm, the percentage is weight percentage. The thickness of a layer A accounts for 8% of the total thickness of the reflective film substrate, the thickness of the B layer accounts for 84% of the total thickness of the reflective film substrate, the thickness of the reflective film substrate is 188 μm, and the coating thickness is 20 μm. The relevant properties are shown in Table 2.

Embodiment 2

[0051] In the reflective film with high diffuse reflectivity provided by the present invention, the ratio of layer A is 82% of PET chips and 18% of silicon dioxide particles. The ratio of layer B is 86% PET chips, 7% rutile TiO 2 , 3% cyclic olefin copolymer resin, 4% antistatic agent. The coating ratio is 71% solvent (butanone: toluene = 1:1), 23% water-based polyurethane adhesive, 2% aliphatic polyisocyanate, 1% polymethyl methacrylate particles with a particle size of 20-25 μm , 3% polystyrene particles with a particle size of 10-15 μm, the percentages are weight percentages. The thickness of a layer A accounts for 8% of the total thickness of the reflective film substrate, the thickness of the B layer accounts for 84% of the total thickness of the reflective film substrate, the thickness of the reflective film substrate is 188 μm, and the coating thickness is 20 μm. The relevant properties are shown in Table 2.

Embodiment 3

[0053] In the reflective film with high diffuse reflectivity provided by the present invention, the ratio of layer A is 85% of PET chips and 15% of silicon dioxide particles. The ratio of layer B is 82% PET chips, 9% rutile TiO 2 , 4% polymethylpentene, 5% antistatic agent. The coating ratio is 67% solvent (toluene: ethyl acetate = 1:1), 25% epoxy resin adhesive, 3% aliphatic polyisocyanate, 1% polybutylmethacrylate with a particle size of 25-30μm Ester particles, 4% of polystyrene particles with a particle size of 10-15 μm, the percentage is by weight. The thickness of a layer A accounts for 8% of the total thickness of the reflective film substrate, the thickness of the B layer accounts for 84% of the total thickness of the reflective film substrate, the thickness of the reflective film substrate is 188 μm, and the coating thickness is 20 μm. The relevant properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com