Carbon material adopting Zr-MOFs composite material as template, preparation method and application of carbon material

A technology of composite materials and carbon materials, applied in the field of carbon materials based on Zr-MOFs composite materials as templates and its preparation, can solve the problems of poor stability MOFs, etc., and achieve channel adjustability, template selectivity diversification, high ratio The effect of capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The specific operation steps of the carbon material preparation method based on the Zr-MOFs composite material as the template of the present invention are as follows:

[0031] Step (1), take the mass as (1.0mmol) ZrCl 4 and aminoterephthalic acid (H 2 BDC, 1.0mmol) Use 20 mL of DMF solvent to ultrasonically prepare the mixed solution of the two, take carboxylated graphene with a mass of 0.5% of the above mixture, and use 15 mL of N,N-dimethylformamide (DMF) solvent to ultrasonically prepare Graphene solution, and then ultrasonically mix all the prepared solutions;

[0032] Step (2), transfer all prepared solutions into a stainless steel reaction kettle, place the reaction kettle in an oven with temperature control at 120°C in advance for reaction, and keep it warm for 48 hours. The obtained precipitate is centrifugally washed with DMF, filtered, and then Dry at 120°C to obtain the sample;

[0033] Step (3), put the obtained sample into the tube furnace, under N 2 C...

Embodiment 2

[0038] The steps not particularly described are the same as those in Example 1, except that in step (3), the heating carbonization treatment temperature is 900°C.

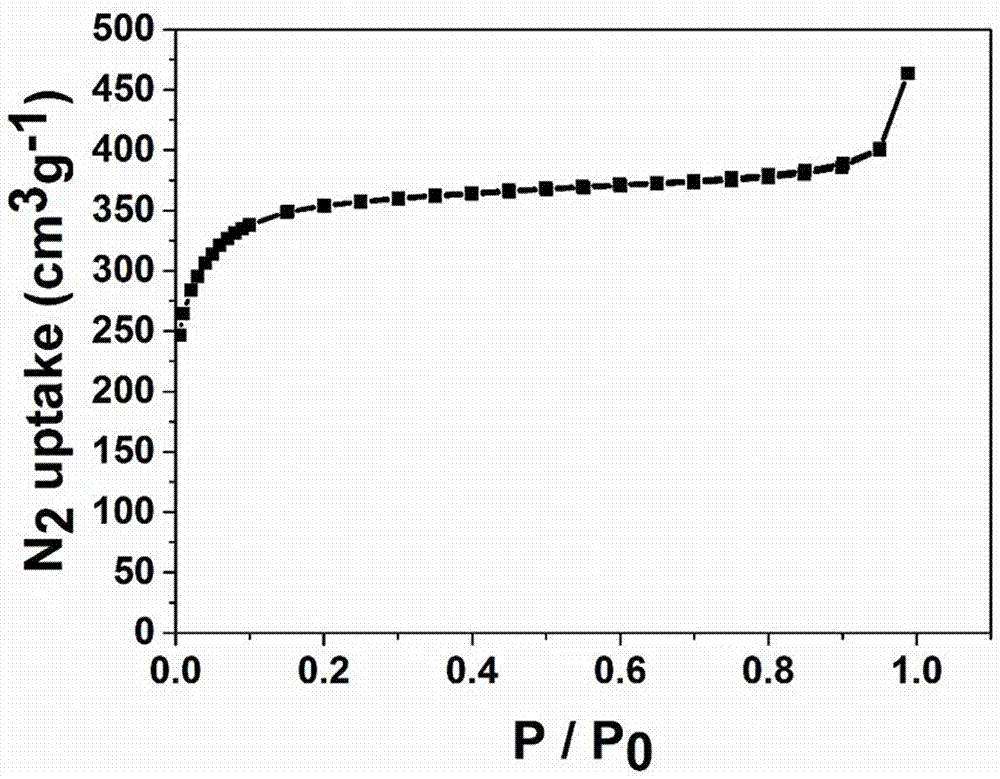

[0039] The test condition for the low-temperature nitrogen isothermal adsorption performance of the carbon material of the present invention is degassing at 200° C. for 8 hours, and then performing nitrogen isothermal adsorption and desorption test at 77 K. The result is as Figure 4Shown, embodiment 2 gained material specific surface area reaches 1315 m 2 g -1 .

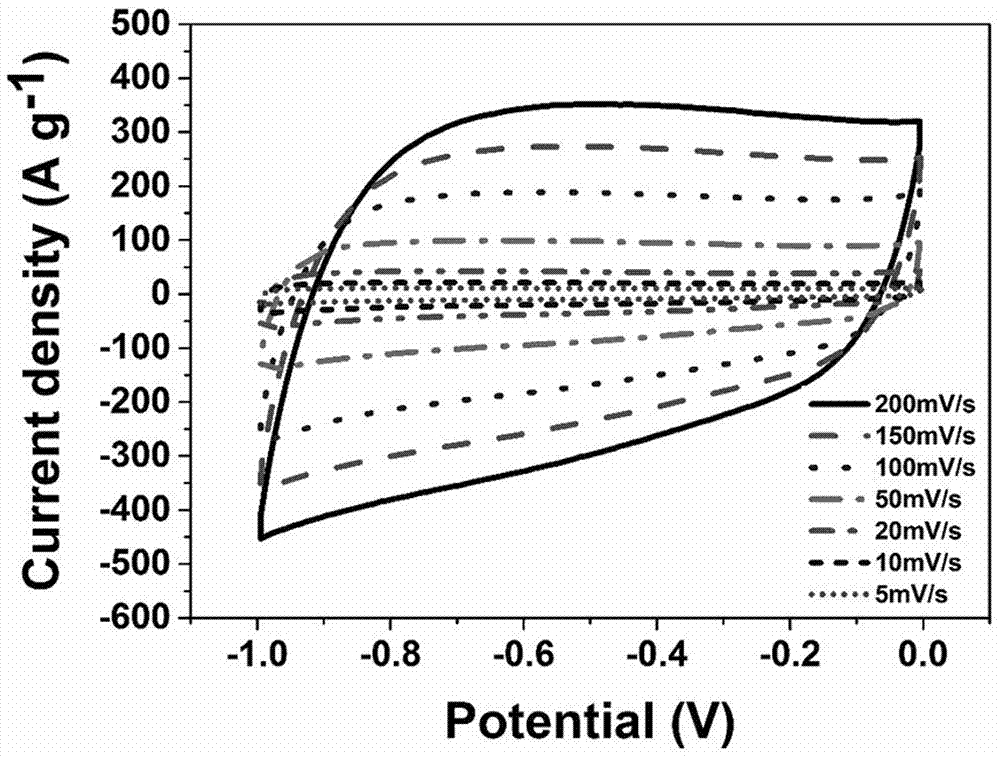

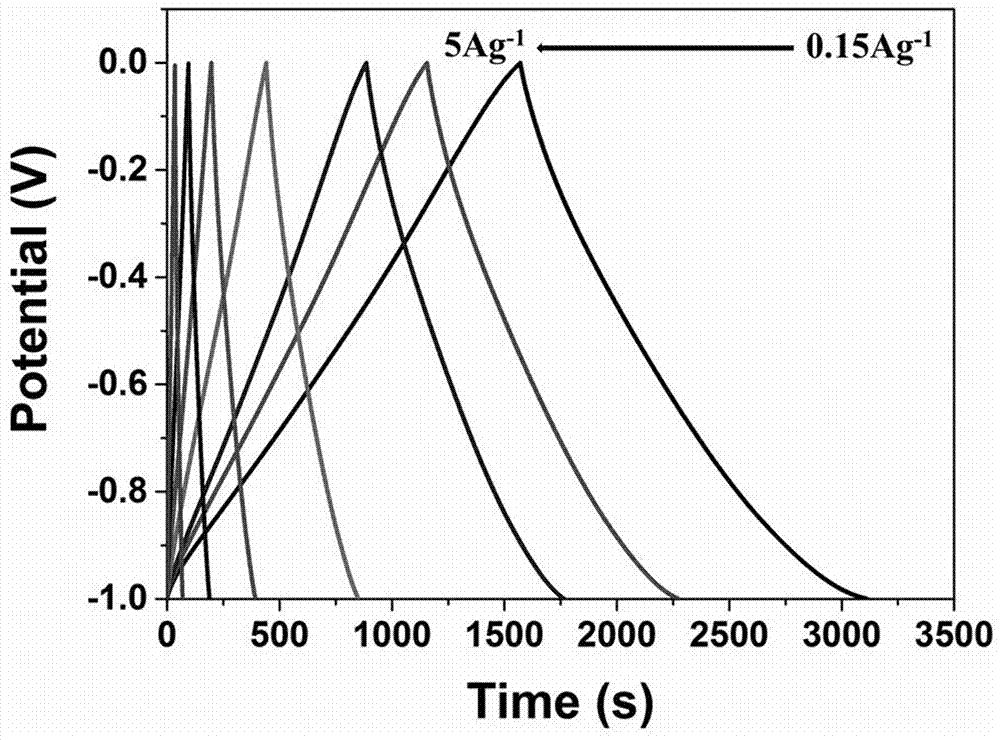

[0040] The application of the carbon material of the present invention as an electrode material of a supercapacitor, its electrochemical performance test is carried out on an electrochemical workstation. Including cyclic voltammetry curve, test results such as Figure 5 As shown, at different scan rates, the cyclic voltammetry curves maintain a good rectangular shape, indicating good electric double layer capacitive behavior and electrochemical rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com