Resistive thin-film memory and preparation method thereof

A technology of resistive switching film and memory, which is applied in the direction of electrical components, etc., can solve the problems of the performance consistency of the resistive switching unit, the inability to pre-control the area, and the randomness of the conductive channel, so as to achieve improved performance and superior performance. Good control and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

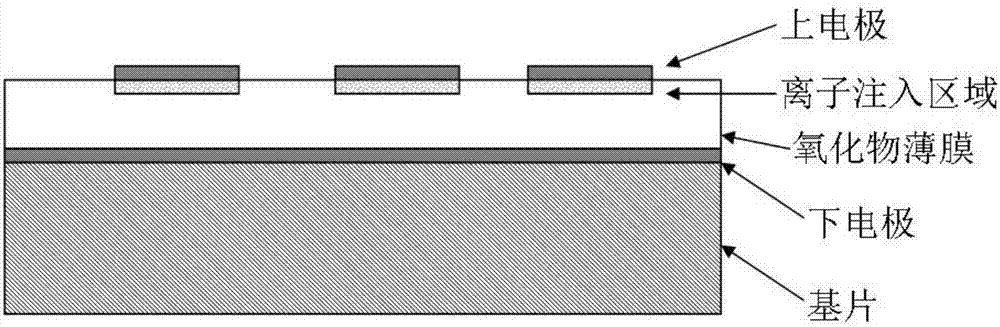

[0023] Step 1. Select a silicon substrate with a platinum electrode, and prepare a lithium niobate film with a thickness of 300 nm on one side of the platinum electrode.

[0024] Step 2, setting the locally implanted area as a photolithography mask with three circular areas with a diameter of 50 μm.

[0025] Step 3. Use the photolithography mask in step 2 to complete the photolithographic patterning process, so that the local area where the film needs to be injected (a circular area with a diameter of 50 μm) is not covered by photoresist, while the rest of the film is covered with light. Etch cover.

[0026] Step 4. Use the ions emitted by the argon ion source to perform ion implantation on the side of the silicon substrate covered with photoresist. The implantation depth is 50nm. At this time, the photoresist acts as a protective mask. Ion implantation is only possible in localized regions of the film covered with glue.

[0027] Step 5, using a sputtering method to first pr...

Embodiment 2

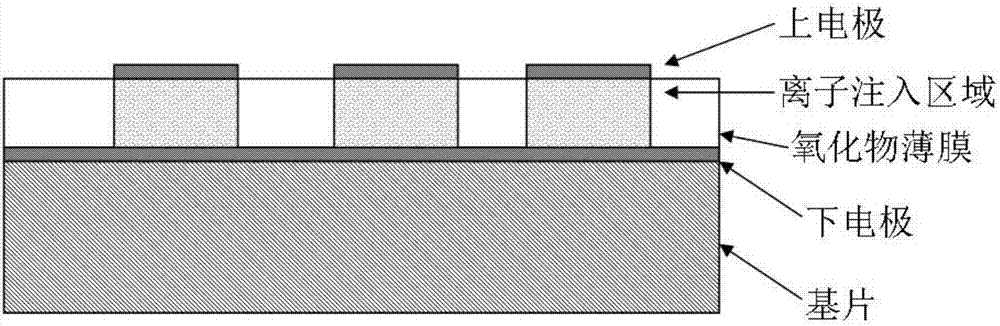

[0029] Step 1. Select a silicon substrate with a platinum electrode, and prepare a lithium niobate film with a thickness of 300 nm on one side of the platinum electrode.

[0030] Step 2, setting the locally implanted area as a photolithography mask with three circular areas with a diameter of 50 μm.

[0031] Step 3. Use the photolithography mask in step 2 to complete the photolithographic patterning process, so that the local area where the film needs to be injected (a circular area with a diameter of 50 μm) is not covered by photoresist, while the rest of the film is covered with light. Etch cover.

[0032] Step 4. Use the ions emitted by the argon ion source to perform ion implantation on the side of the silicon substrate covered with photoresist. The implantation depth is 300nm. At this time, the photoresist acts as a protective mask. Ion implantation is only possible in localized regions of the film covered with glue.

[0033] Step 5, using a sputtering method to first p...

Embodiment 3

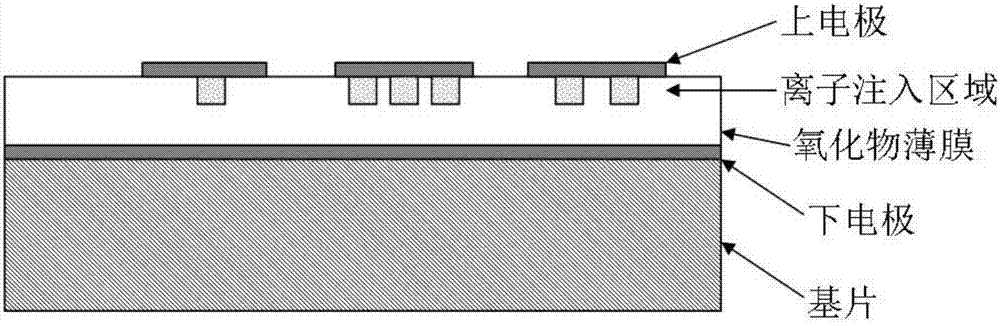

[0035] Step 1. Select a silicon substrate with a platinum electrode, and prepare a lithium niobate film with a thickness of 300 nm on one side of the platinum electrode.

[0036] Step 2, setting the locally implanted area as a photolithography mask of six circular areas with a diameter of 10 μm.

[0037] Step 3. Use the photolithography mask in step 2 to complete the photolithographic patterning process, so that the local area where the film needs to be injected (a circular area with a diameter of 10 μm) is not covered by photoresist, while the rest of the film is covered with light. Etch cover.

[0038] Step 4, using the ions emitted by the argon ion source to perform ion implantation on the side covered with photoresist, and the implantation depth is 200nm. At this time, only the film in the local area not covered by photoresist can have ion implantation.

[0039] Step 5. Set the area of the upper electrode as a photolithographic mask with three square areas with a side l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com